Negative pressure type microorganism grouting device

A microbial and negative pressure technology, applied in the field of negative pressure microbial grouting device, can solve problems such as dependence, and achieve the effect of reducing production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

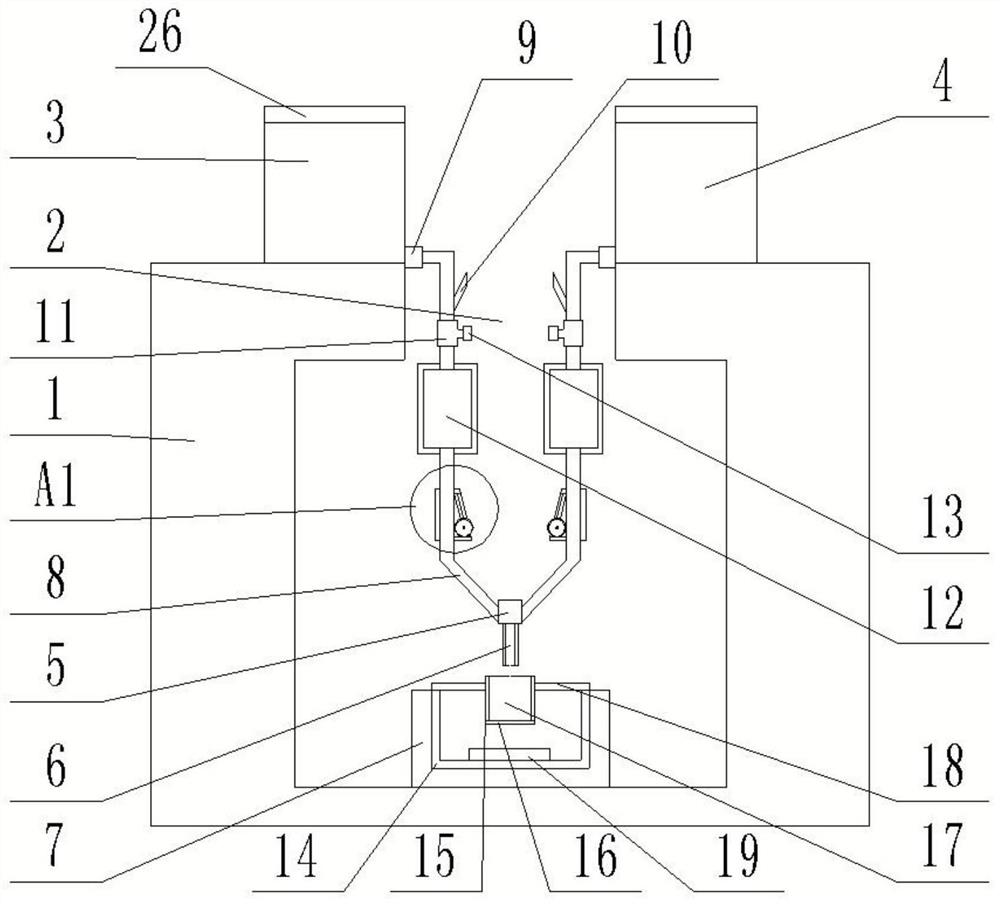

[0023] refer to Figure 1-2 , the present invention provides a negative pressure microbial grouting device, which is characterized in that it includes: a test case 1, a communication hole 2 is provided on the top surface of the test case 1, and a nutrient solution cylinder 3 and a mixed liquid cylinder are provided on the top surface of the test case 1 4. The nutrient solution cylinder 3 and the mixing liquid cylinder 4 are arranged symmetrically with respect to the communication hole 2. The outer walls of the bottom of the nutrient solution cylinder 3 and the mixing liquid cylinder 4 are connected with a drip irrigation mechanism. Connected with a conduit 6, the bottom surface of the inner cavity of the test shell 1 is provided with a constant temperature box 7, and a sample is arranged in the constant temperature box 7, and the conduit 6 corresponds to the position of the sample;

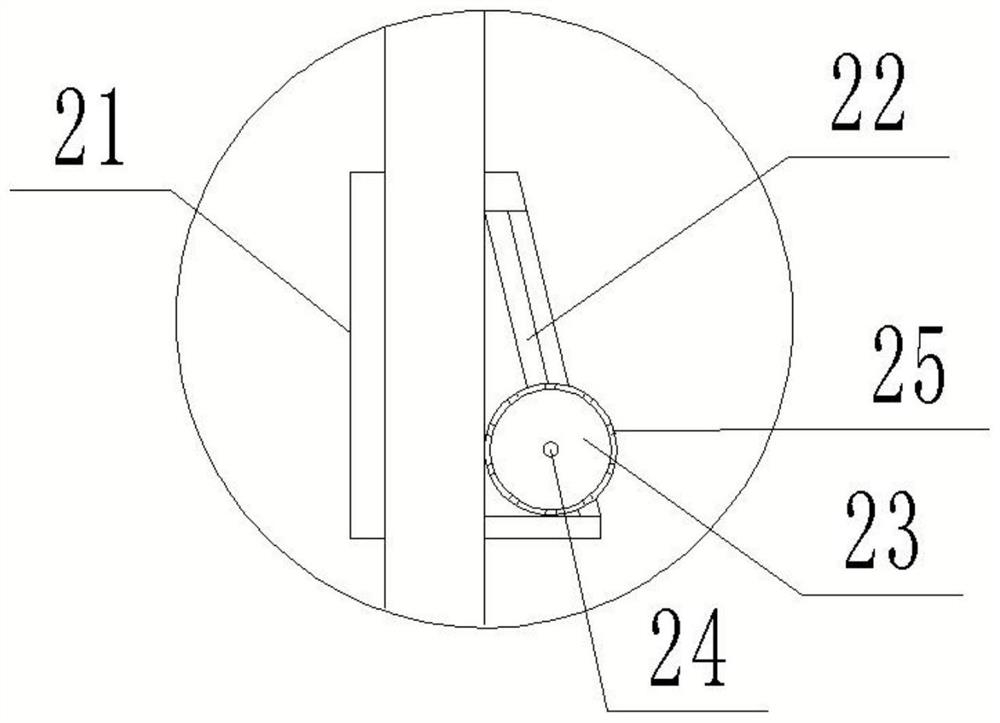

[0024] The drip irrigation mechanism includes a hose 8, the tops of the two hoses 8 communicat...

Embodiment 2

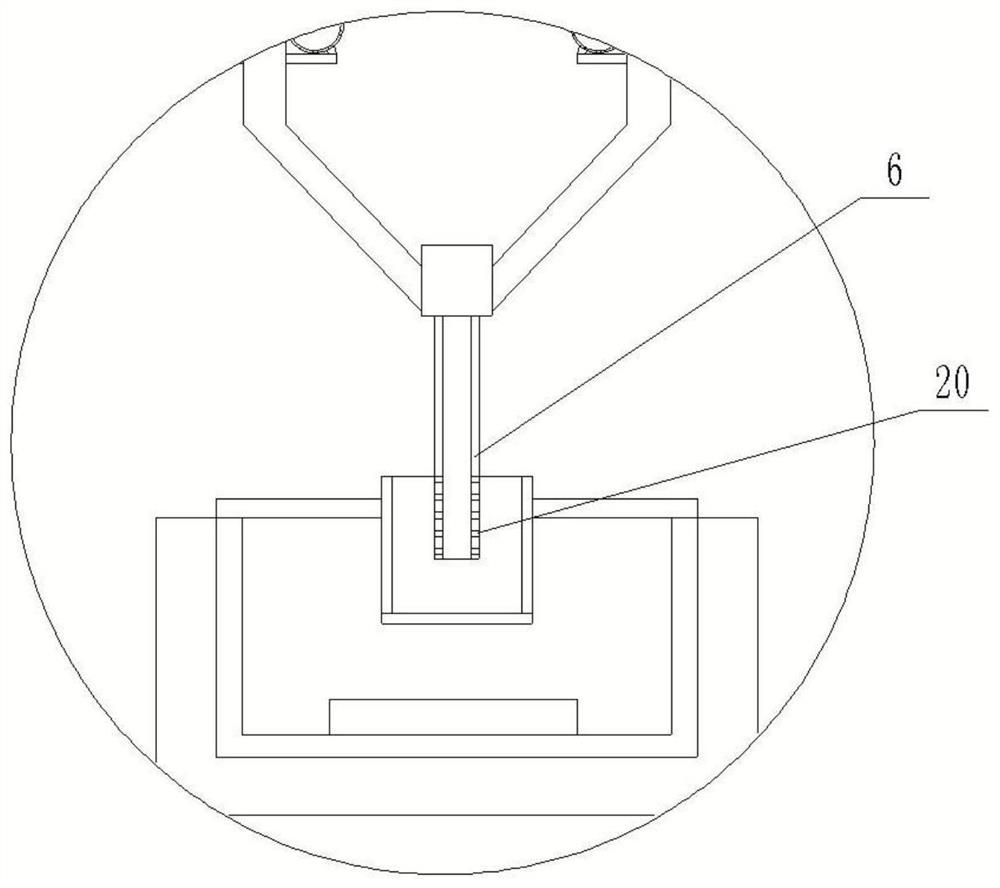

[0039] refer to image 3 , to further optimize the scheme, the bottom of the outer wall of the conduit 6 is provided with a number of penetration holes 20, the top of the conduit 6 communicates with the bottom of the stopcock 5, the bottom end of the conduit 6 is set inside the sample body 17, and several penetration holes 20 are located in the sample body Within 17.

[0040] The arrangement of the permeable holes 20 can realize grouting inside the sample body 17 and improve the grouting efficiency.

Embodiment 3

[0042] refer to Figure 4 , the support seat 18 includes a support ring 27, the support ring 27 is sleeved outside the sample cylinder 15, a number of clamping mechanisms are arranged at equal intervals on the inner wall of the support ring 27, and a number of observation mechanisms are arranged at equal intervals on the top surface of the support ring 27 in the circumferential direction. The hole 28, the top surface of the support ring 27 abuts against the top surface of the connecting cylinder 14; the clamping mechanism and the observation hole 28 are arranged at intervals;

[0043] The clamping mechanism includes a clamping rod 29, one end of the clamping rod 29 is fixedly connected with a rubber pad 30, the inner wall of the support ring 27 is provided with a clamping groove 31, and the other end of the clamping rod 29 is located in the clamping groove 31, and the clamping groove 31 both sides are provided with reset groove 32, and snap-in rod 29 both sides are affixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com