An Evaporative Cooling External Cooling System for DC Converter Station

A DC converter station, evaporative cooling technology, applied in the cooling/ventilation of substations/switchgear, water shower coolers, direct contact heat exchangers, etc., can solve the problem of insufficient cooling efficiency, waste of resources, and low work efficiency To achieve the effect of speeding up the evaporation of spray water, speeding up the circulation of heat and improving work efficiency

Active Publication Date: 2022-05-31

国网湖北省电力有限公司直流公司

View PDF19 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in the evaporative cooling type external cooling system of the existing DC converter station, the circulating water pump is manually started to realize the circulation of cooling water and spray cooling, which is time-consuming and laborious, with low work efficiency and serious waste of resources, and it is difficult to automatically cool the cooling water. Carry out circulating transportation and cooling, and the cooling method of cooling water is single, the cooling efficiency is not high enough, the effect is poor, and it is very inconvenient to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

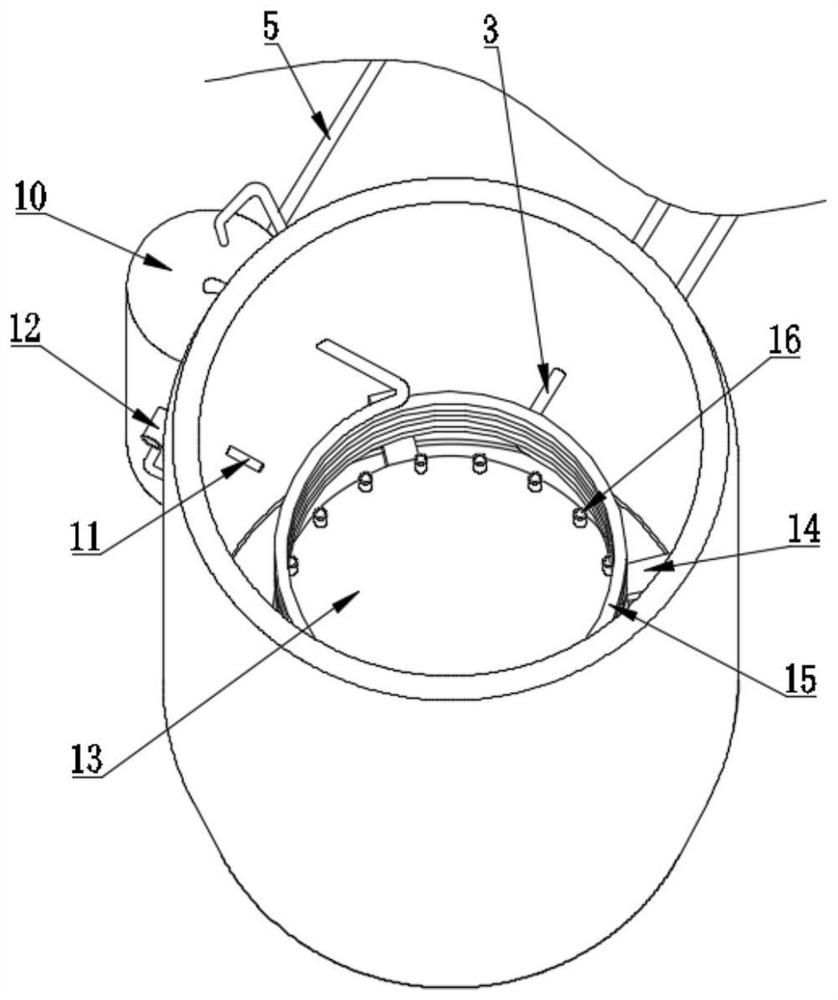

[0030] The circulation mechanism includes a second magnetic slide plug 23 that is located inside the circulation chamber 20 and is slidably connected to the inner wall of the circulation chamber 20,

[0032] The first partition 25 and the first magnetic slide plug 18 are provided with the first magnetic slide plug 18 to move up to the second cooling water.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

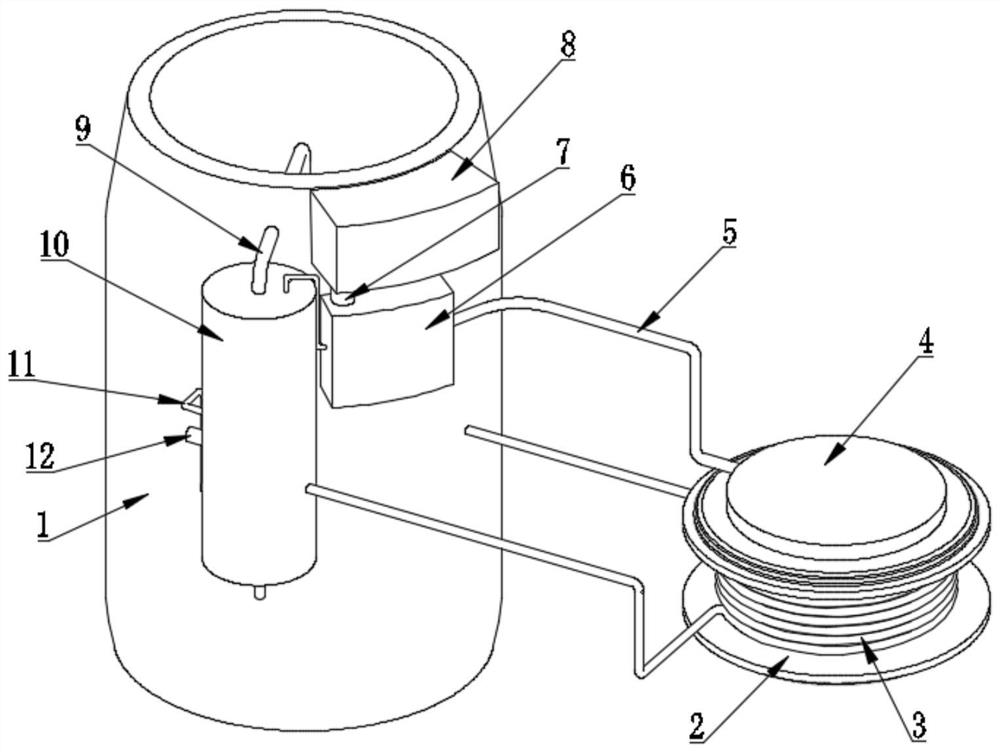

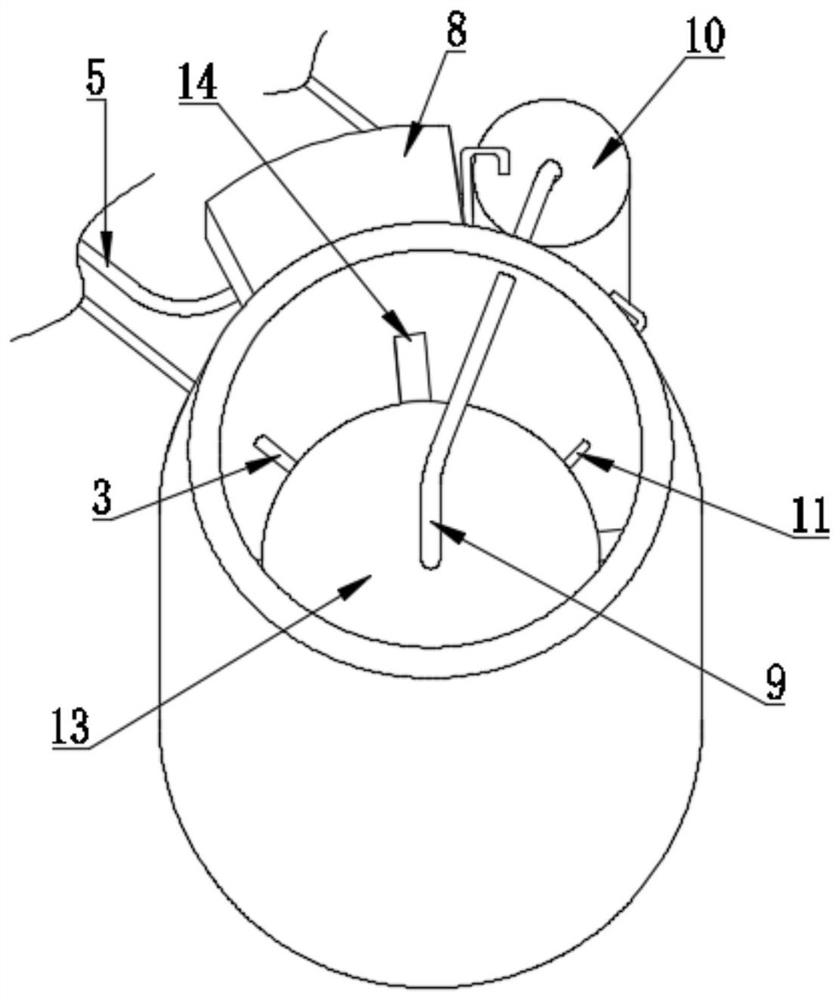

The invention discloses an evaporative cooling type external cooling system for a DC converter station, which includes a heating component, a first cooling water pipe spirally surrounds the outer side of the heating component, a hollow storage plate is arranged on the top of the heating component, Thermal expansion fluid is arranged in the hollow storage tray, an external cooling tower is arranged on one side of the heating component, and a hollow cavity, a water storage tank and a water replenishment tank are fixedly installed on the outer side of the outer cooling tower. The present invention not only can automatically exchange the cooling water in the first cooling water pipe, the circulation chamber and the second cooling water pipe when the temperature of the heating component is high, realizes the self-circulation of the cooling water, cools down the heating component, is convenient to use, and can also be used in After the cooling water is exchanged, the second cooling water pipe is automatically sprayed and blasted, and the evaporation of the sprayed water is used to speed up the heat exchange and the cooling effect is better. Suitable for converter stations.

Description

An evaporative cooling external cooling system for DC converter station technical field The present invention relates to evaporative cooling technical field, relate in particular to a kind of evaporative cooling type external cooling for direct current converter station But the system. Background technique At present, in the evaporative cooling type external cooling system of the existing direct current converter station, it is mostly realized by manually starting the circulating water pump. The current circulation and spray cooling of cooling water are time-consuming and labor-intensive, with low work efficiency and serious waste of resources. The cooling water is circulated and transported and cooled. At the same time, the cooling method of the cooling water is single, the cooling efficiency is not high enough, and the effect is poor. Very inconvenient. SUMMARY OF THE INVENTION The object of the present invention is to solve the shortcoming existing in the prio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02B1/56F28C1/00F28F27/00

CPCH02B1/56F28C1/00F28F27/003F28C2001/006Y02E60/60

Inventor 陈建宝周广韩情涛宁波史册陈大军戴迪杨文李少翀饶洪林

Owner 国网湖北省电力有限公司直流公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com