Assembling frame for manufacturing hollow fiber membrane module and automatic assembling device

A fiber membrane and assembly frame technology, applied in the field of water treatment, can solve the problems of difficult operation, high labor cost, heavy weight, etc., and achieve the effects of low product scratch rate, high degree of automation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

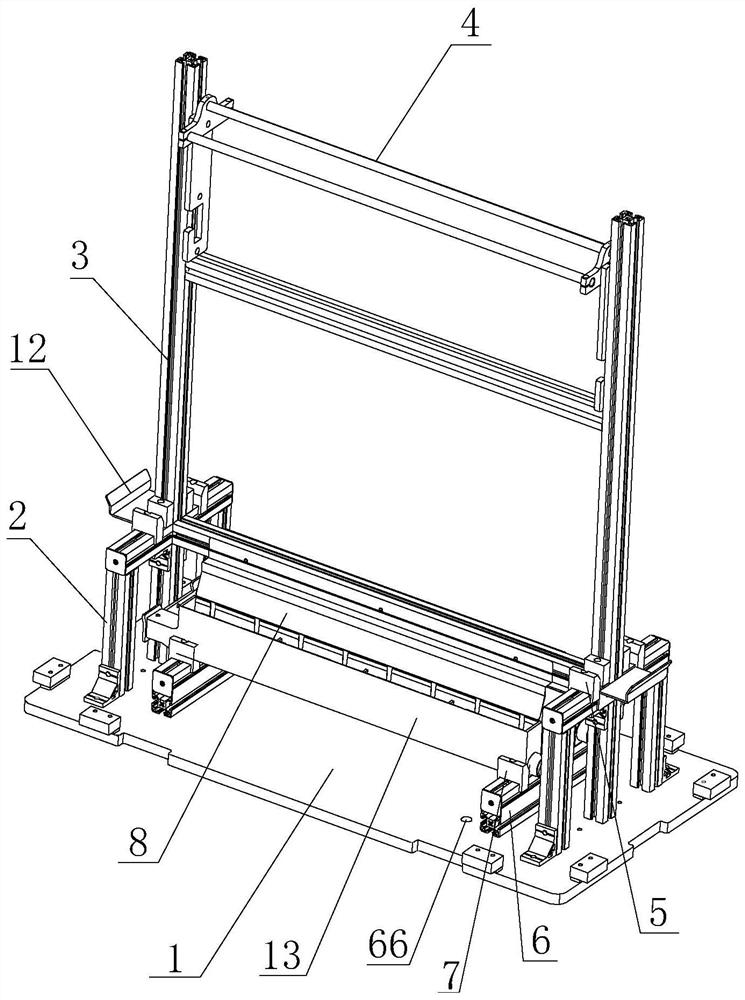

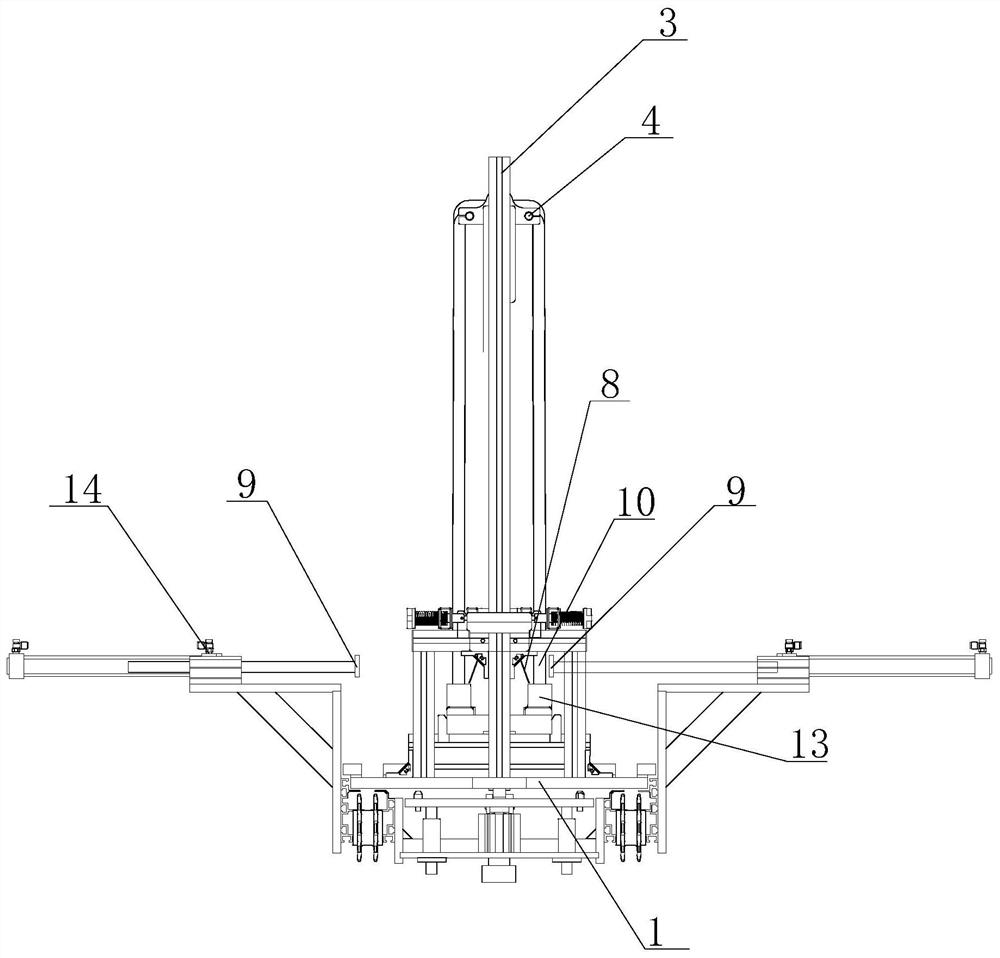

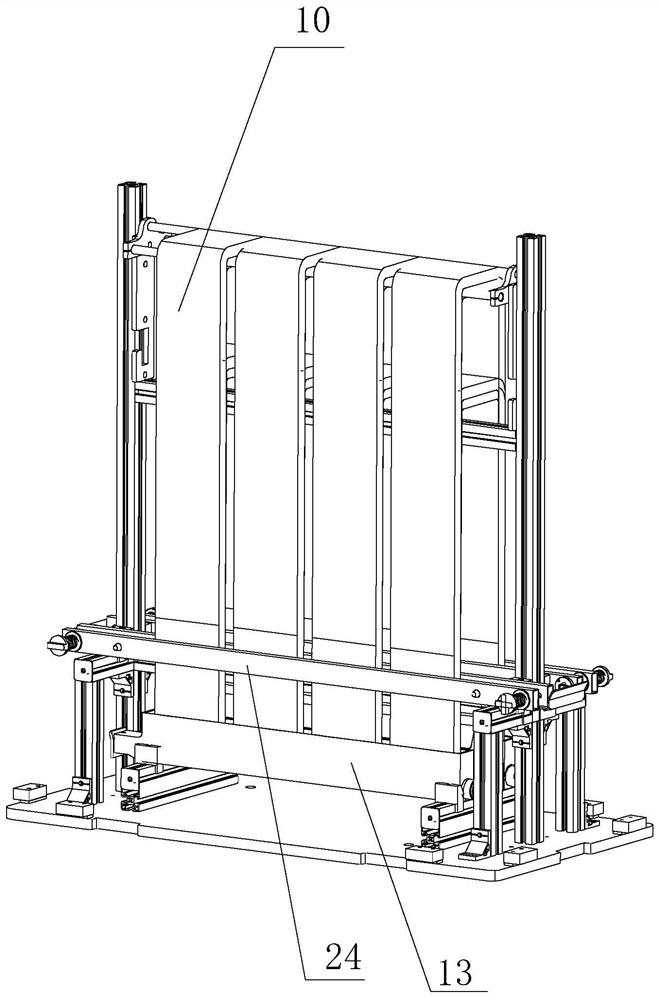

[0025] The present invention will be further described below in conjunction with FIGS. 1-7 and specific embodiments.

[0026] An assembly frame for making hollow fiber membrane modules, as attached figure 1 , 2 , 3, including the diaphragm clamp 24, the assembly frame body and the outer guide block 9, the assembly frame body is as attached figure 1 As shown, it includes a support frame 2, a vertical support bar 3 is fixedly connected to the left and right sides of the support frame 2, two horizontal support bars 4 are connected between the support bars 3, and two horizontal support bars 4 are respectively arranged on the left and right sides of the support frame 2. For the diaphragm clamp holder 5, two pairs of diaphragm clamp holders 5 are respectively distributed on the front and rear sides of the support rod 3, the water collection pipe positioning frame 6 is arranged inside the support frame 2, and the left and right sides of the water collection pipe positioning frame 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com