Treatment system for coal sample containers

A coal sample and processing system technology, applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of difficult sample container handling, affecting the detection efficiency of coal samples, etc., to ensure normal detection efficiency and management Convenient and efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

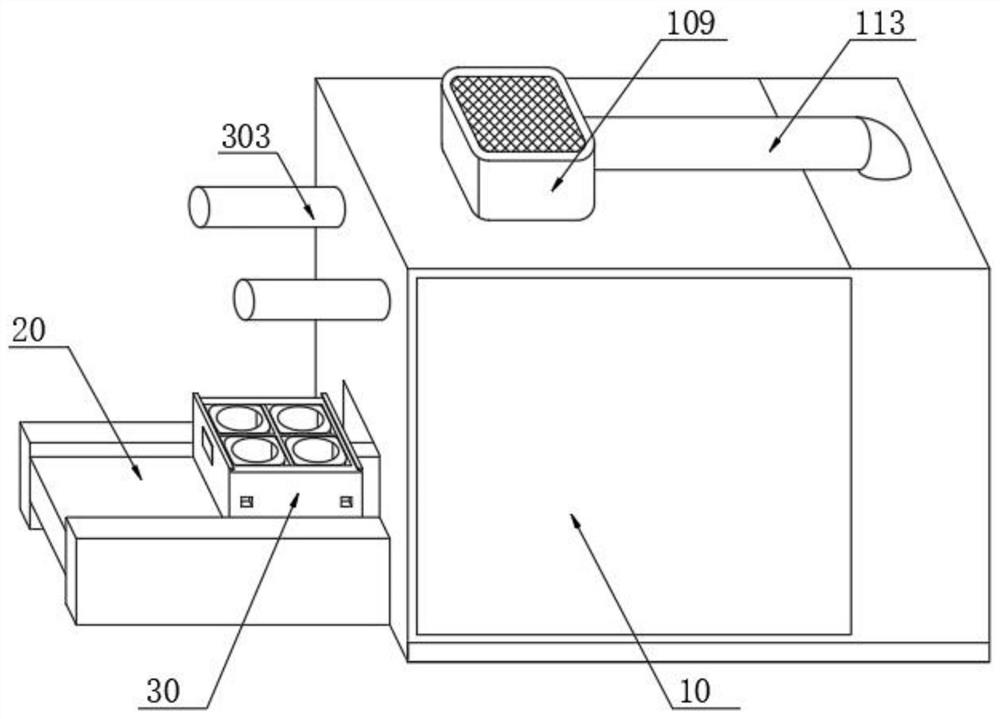

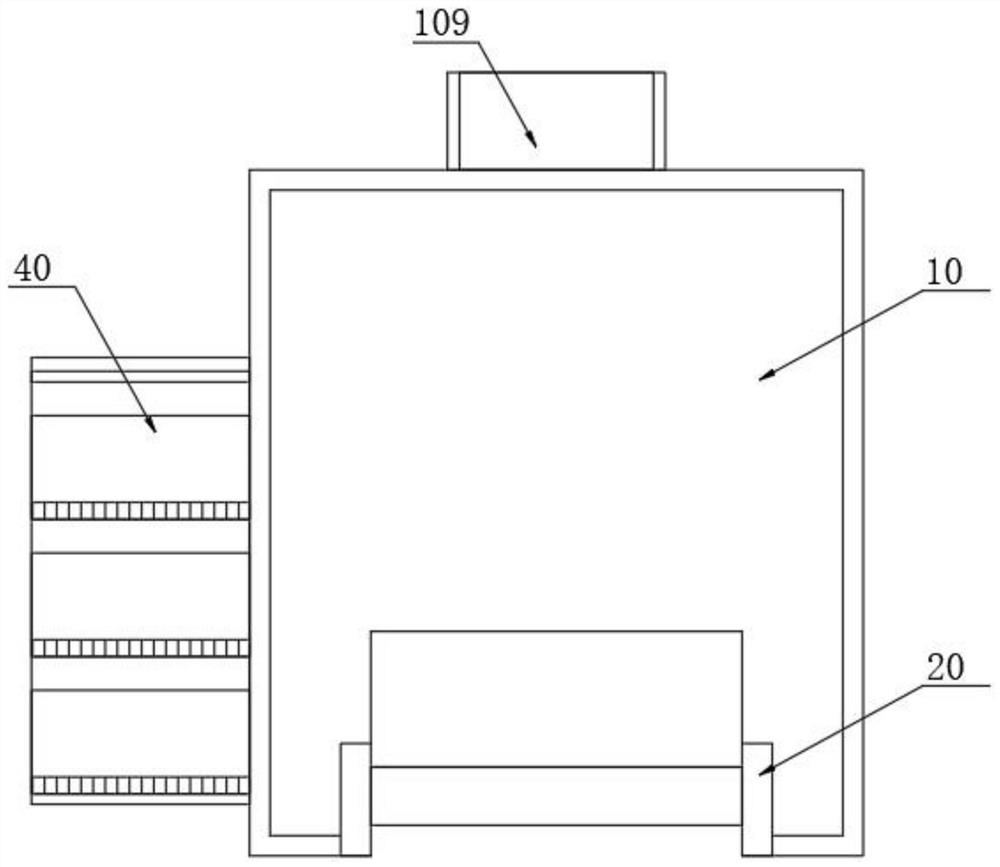

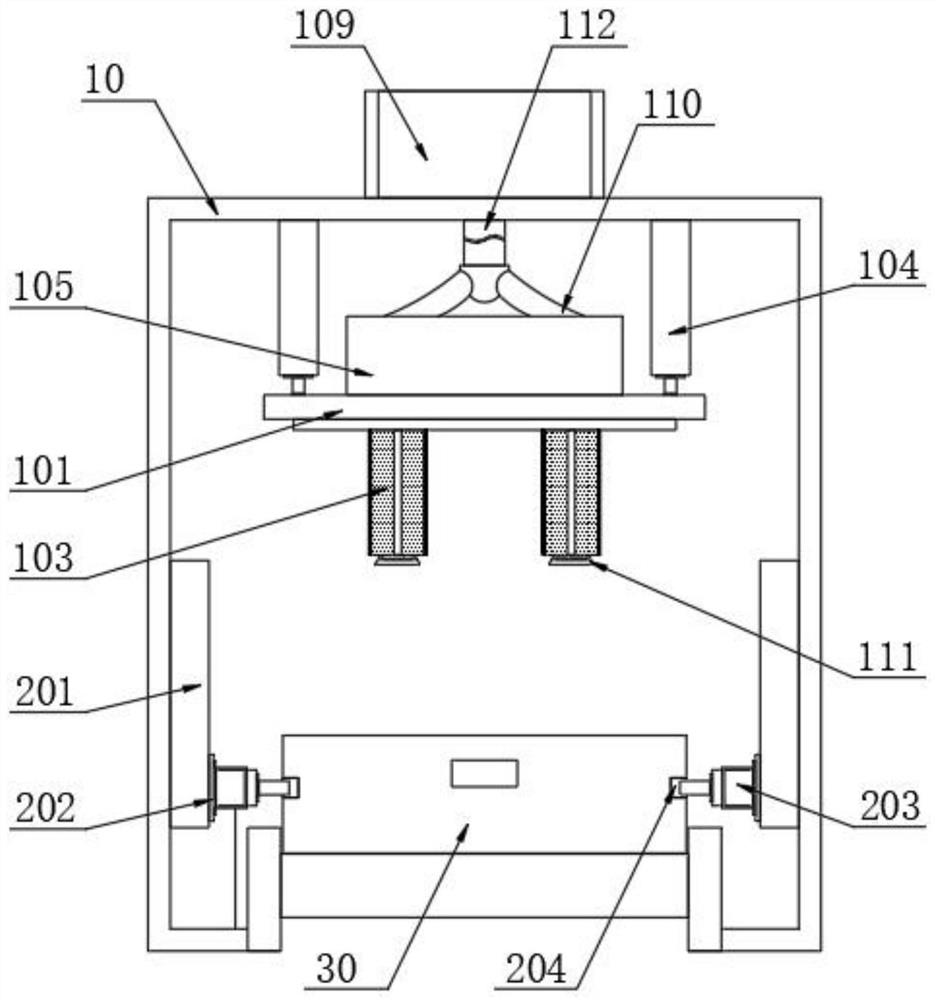

[0041] see Figure 1-8 As shown, a coal sample container processing system includes a processing box 10 and a transport rack 20, one side of the transport rack 20 extends to the inside of the processing box 10, and a discharge rack 30 is placed on the top of the transport rack 20, and the transport rack 20 is used to 20. The discharge rack 30 is sent into the inside of the processing box 10, and the coal sample container after detection and processing is placed inside the discharge rack 30, wherein at least four coal sample containers are placed in the inside of the discharge rack 30. The interior of the box 10 and the front and rear sides of the transport rack 20 are symmetrically provided with two lifting components, and the discharge rack 30 above the transport rack 20 is lifted by the two lifting components, thereby facilitating the coal samples in the discharge rack 30. The interior of the container is cleaned. A cleaning mechanism is provided on the top of the inner wall...

Embodiment 2

[0047] In the present invention, the cleaning mechanism also includes a material pump 109 arranged on the top of the processing box 10. Several collecting pipes 110 are arranged inside the driving box 105, and the bottom ends of several collecting pipes 110 extend to several cleaning rollers respectively. Inside 102, there is a certain movable gap on the inner wall of the cleaning roller 102 on the surface of the collecting pipe 110, and the bottom end of the collecting pipe 110 is connected with a pumping port 111, and the feeding end of the pumping pump 109 is connected with a pumping pipe 112, and the inside of the pumping pipe 112 is connected with several collecting pipes 110 respectively, wherein the pumping pipe 112 adopts a flexible pipe, and the flexible pipe can cooperate with the movable frame 101 to carry out the operation of lifting up and down as a whole, and the discharge of the pumping pump 109 A discharge pipe 113 is communicated with the end, and a collection ...

Embodiment 3

[0050] In the present invention, the lifting assembly includes a fixed plate 201 positioned at the front and back of the inner wall of the processing box 10, and the opposite sides of the two fixed plates 201 are all movably provided with a linear motor-202, wherein one side of the two linear motors-202 is provided with There is a linear slide rail 1, one side of the two linear motors 202 is provided with a servo electric cylinder 2 203, and one end of the drive shaft of the two servo electric cylinders 203 is provided with a connecting block 204;

[0051] Both the front and the back of the discharge rack 30 are provided with chute 60 , and the insides of the two chute 60 are symmetrically provided with four connection grooves 70 matching with the connection block 204 .

[0052] Push the connection block 204 into the connection groove 70 in the discharge rack 30 through the drive shaft of the servo electric cylinder 2 203, and then lift it on the side of the fixed plate 201 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com