Hydraulic system of variable-amplitude mechanism of crank arm type overhead working truck

A technology of aerial work vehicle and luffing mechanism, which is applied in the directions of fluid pressure actuation system components, cranes, mechanical equipment, etc., can solve the problems of secondary arm bending deformation, damage, deformation of the contact part of the secondary arm and the connecting hub, etc. Achieve the effect of avoiding extrusion damage, prolonging service life and reducing fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

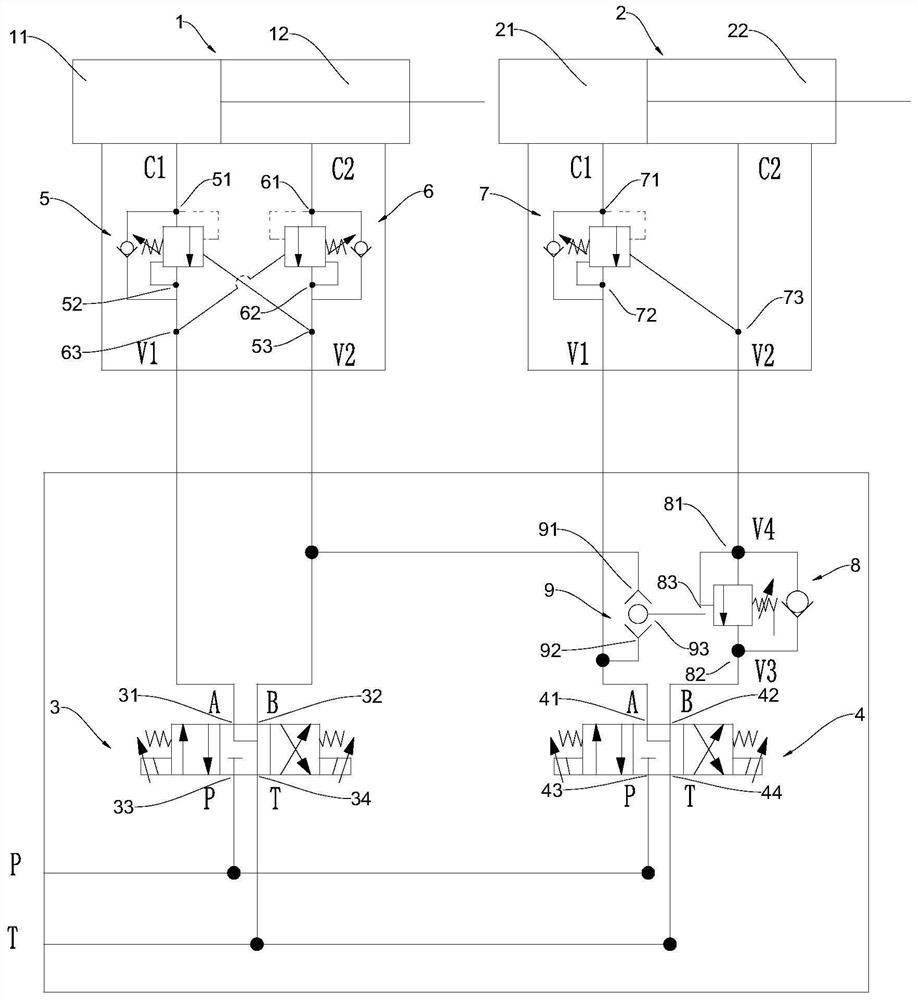

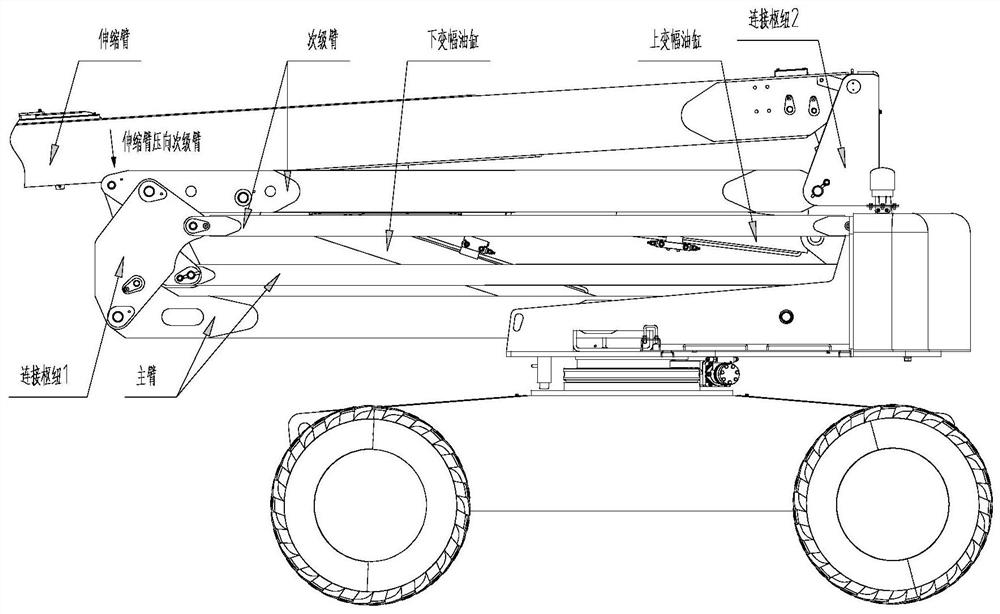

[0019] refer to figure 1 As shown, a hydraulic system of the luffing mechanism of the crank-arm type aerial work vehicle of the present invention includes:

[0020] The upper luffing oil cylinder 1, the upper luffing oil cylinder 1 includes an upper luffing rodless cavity 11 and an upper luffing rod cavity 12;

[0021] The lower luffing oil cylinder 2, the lower luffing oil cylinder 2 includes a lower luffing rodless cavity 21 and a lower luffing rod cavity 22;

[0022] The first reversing valve 3, the first reversing valve 3 includes a first working port 31 and a second working port 32;

[0023] The second reversing valve 4, the first reversing valve 3 includes a third working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com