High-strength and high-conductivity flat steel and manufacturing method and application thereof

A technology of high conductivity and manufacturing method, which is applied in the direction of cable/conductor manufacturing, circuit, metal rolling, etc., can solve the difficulty of further improving the conductivity and strength of conductive steel, and the unification of high conductivity and high strength. Issues such as the development and expansion of the application of conductive steel to achieve the effect of improving conductivity, improving electrical conductivity, and improving service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

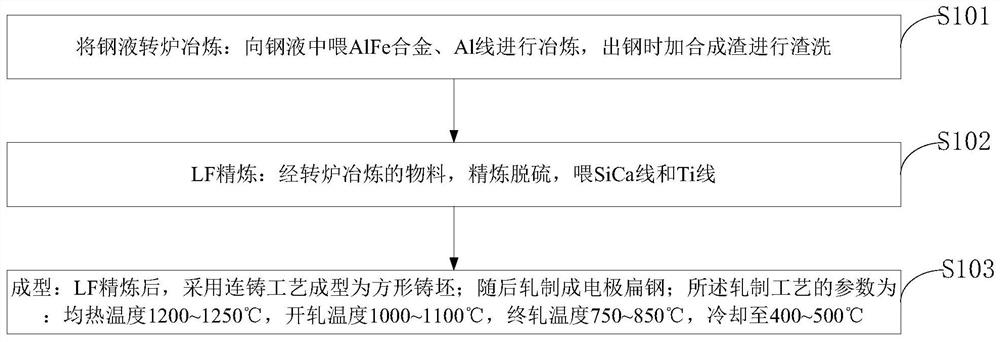

Method used

Image

Examples

Embodiment 1

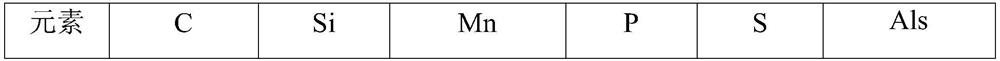

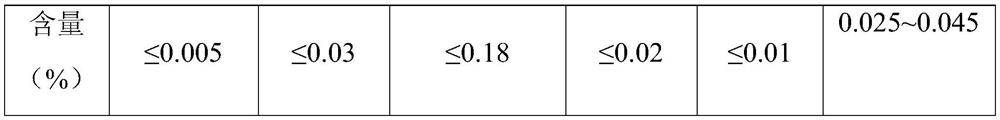

[0189] The high-strength and high-conductivity flat steel described in this embodiment contains 0.006% by weight of C, 0.025% of Ti, 0.05% of Si, 0.2% of Mn, 0.02% of P, 0.004% of S, and the rest is Fe.

Embodiment 2

[0191] The high-strength and high-conductivity flat steel described in this embodiment contains 0.001% by weight of C, 0.03% of Ti, 0.05% of Si, 0.1% of Mn, 0.015% of P, 0.003% of S, and the rest is Fe.

Embodiment 3

[0193] The high-strength and high-conductivity flat steel described in this embodiment contains 0.005% by weight of C, 0.04% of Ti, 0.045% of Si, 0.1% of Mn, 0.015% of P, 0.003% of S, and the rest is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com