Gas cylinder inflation and deflation subsystem suitable for unattended operation

A sub-system, filling and deflation technology, applied in the pipeline system, container filling method, fixed capacity gas storage tank, etc., can solve the problems of excessive leakage rate of the filling and unloading switch, delay of launch mission, gas leakage, etc., and achieve closure The effect of sealing redundancy, improving safety, and improving sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below in conjunction with the accompanying drawings.

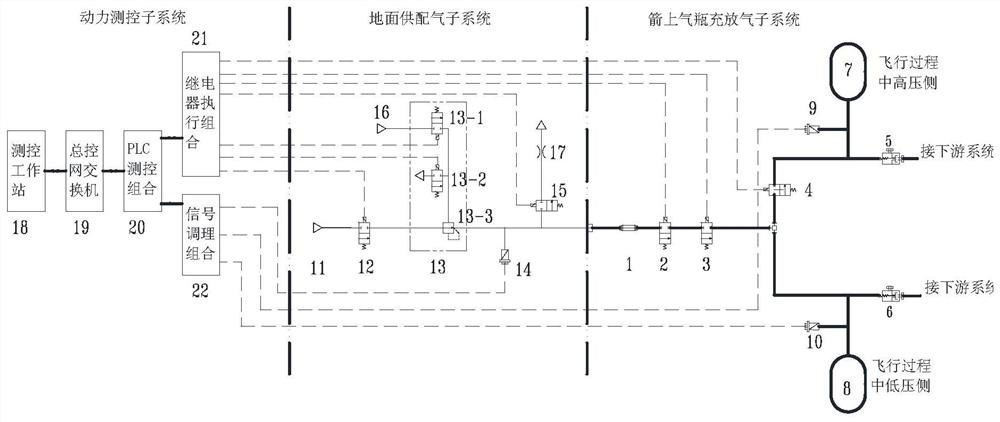

[0040] Such as figure 2 As shown, the present invention is an unattended gas cylinder filling and deflation subsystem, which includes a power measurement and control subsystem, a ground gas supply and distribution subsystem, and an arrow-mounted gas cylinder filling and deflation subsystem. The power measurement and control subsystem includes measurement and control workstation 18, main control network switch 19, PLC measurement and control combination 20, signal conditioning combination 22, and relay execution combination 21; the ground gas supply and distribution subsystem includes ground high-pressure gas source 11, ground solenoid valve 12, electric Pressure reducer 13, post-valve pressure sensor 14, first deflation solenoid valve 15, ground control air source 16, and deflation flow limiting element 17; Upper solenoid valve 2, second arrow upper solenoid valve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com