Oil gas recovery tester

A tester, oil and gas technology, applied in the field of oil and gas recovery tester, can solve the problems of gas station business, complicated installation steps, inconvenient to move, etc., and achieves the effects of flexibility, fast response, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The application will be described in further detail below in conjunction with the accompanying drawings.

[0033] The embodiment of the present application discloses an oil gas recovery tester.

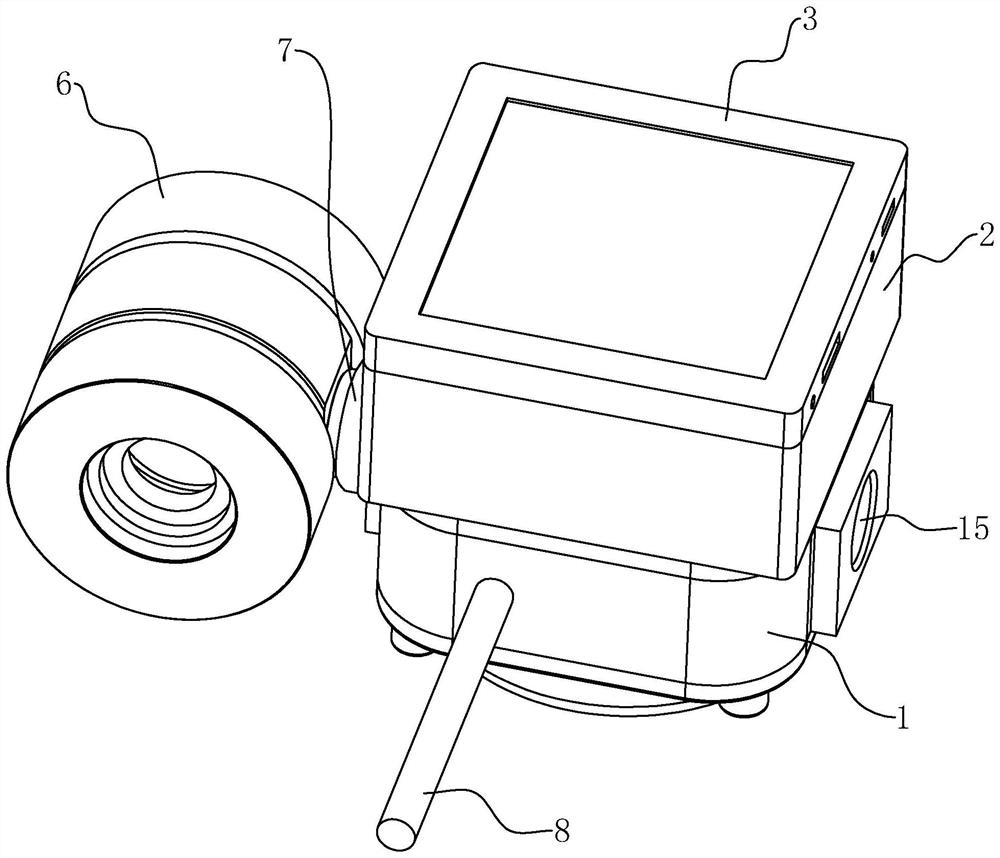

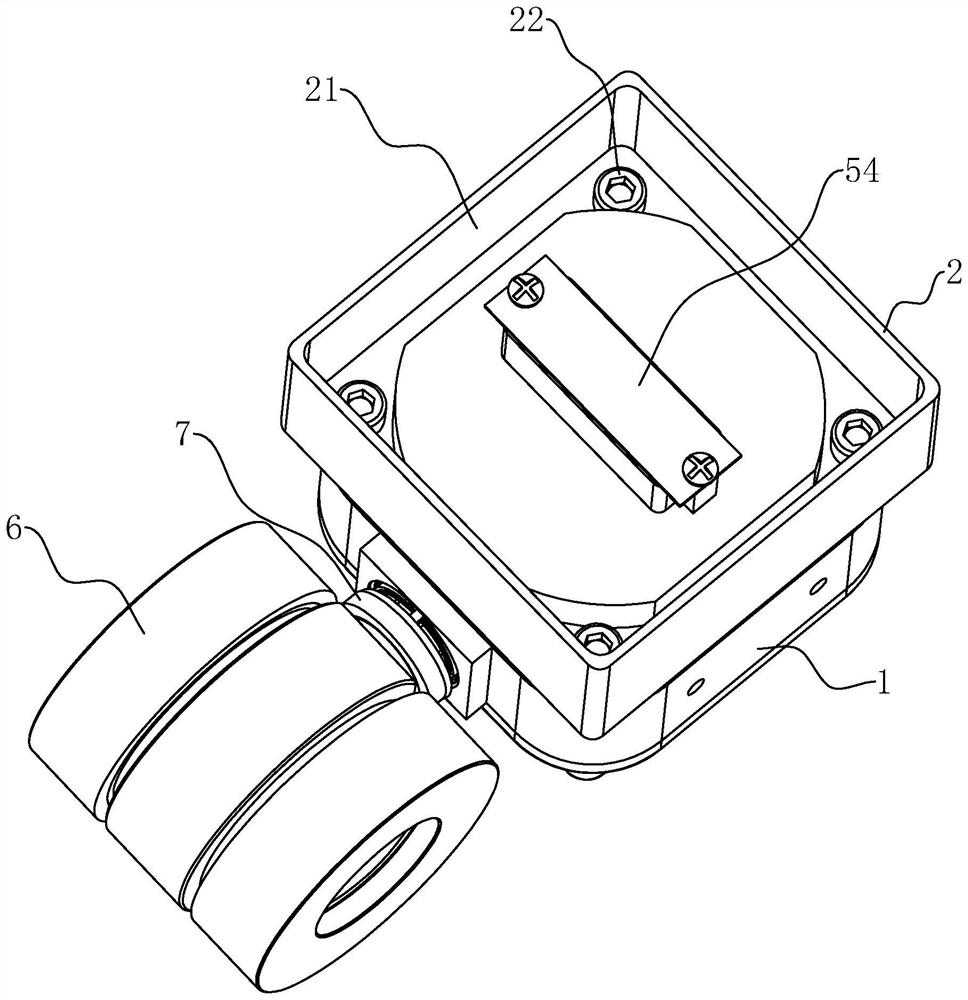

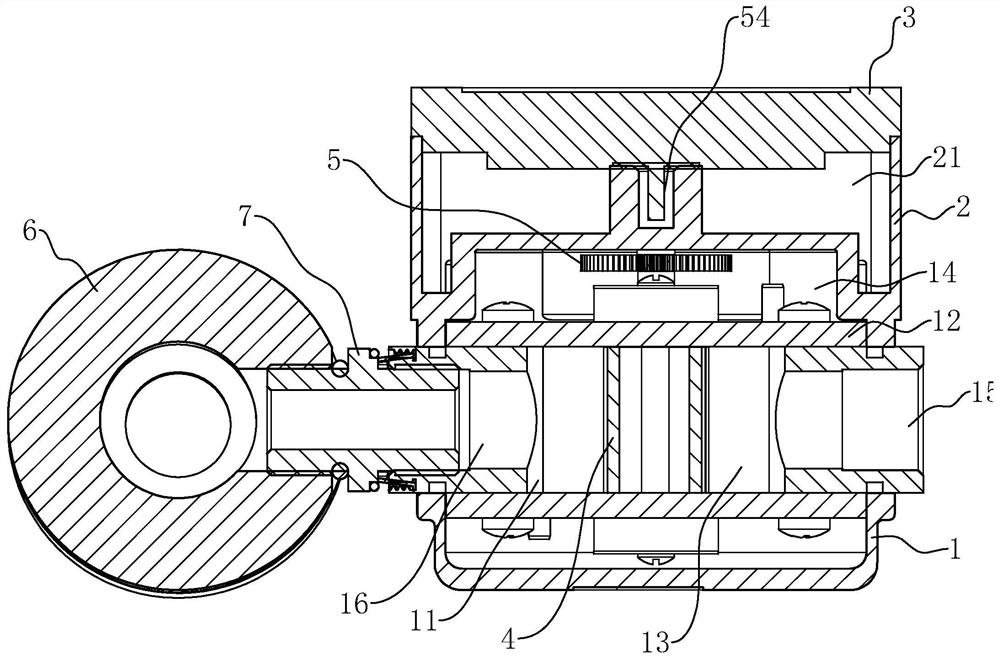

[0034] refer to Figure 1 to Figure 3 The oil and gas recovery tester includes a body, the body includes a base 1, an upper cover 2 that is adapted to the base 1 and forms an installation cavity 11, a touch-screen operation display panel group 3 installed on the outer surface of the upper cover 2, and is rotatably installed on the base The waist wheel set 4 on 1, the gear set 5 that is connected to the waist wheel set 4 through the connecting shaft 43 and rotates synchronously with it, and the adapter 6 that is connected to the side of the base 1 for connecting with the refueling gun.

[0035] refer to Figure 3 to Figure 6 , wherein, the installation chamber 11 is provided with a sealing partition 12 to divide it into a gas flow chamber 13 and a gas metering chamber 14, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com