Decondensation temperature control system

A technology for controlling the system and condensation temperature, which is applied in the direction of electrical components, panel/switch station circuit devices, substation/switch device cooling/ventilation, etc., which can solve the damage of electrical components, increase the space occupied by the decondensation device, Large damage to electrical components, etc., to achieve the effect of reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the description of the invention, it is to be noted that the term "mount", "connected", "connection", such as a fixed connection, unless otherwise expressly specified and defined, unless otherwise expressly specified and defined. Connect, or integrate; may be mechanical connection, or electrical connection; may be directly connected, or indirectly connected by an intermediate medium, which can be in the interior of the two elements. For those skilled in the art, the specific meaning of the above terms can be understood in the art.

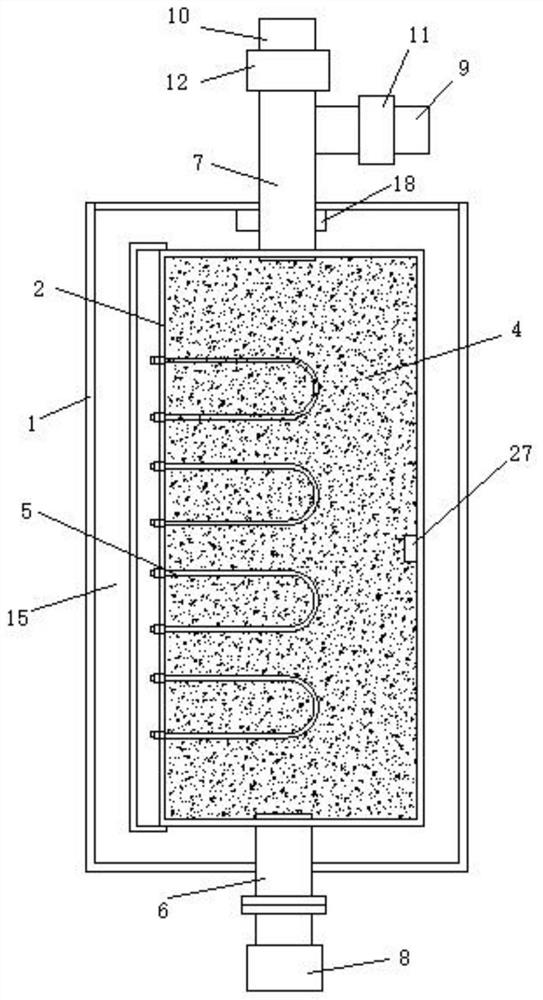

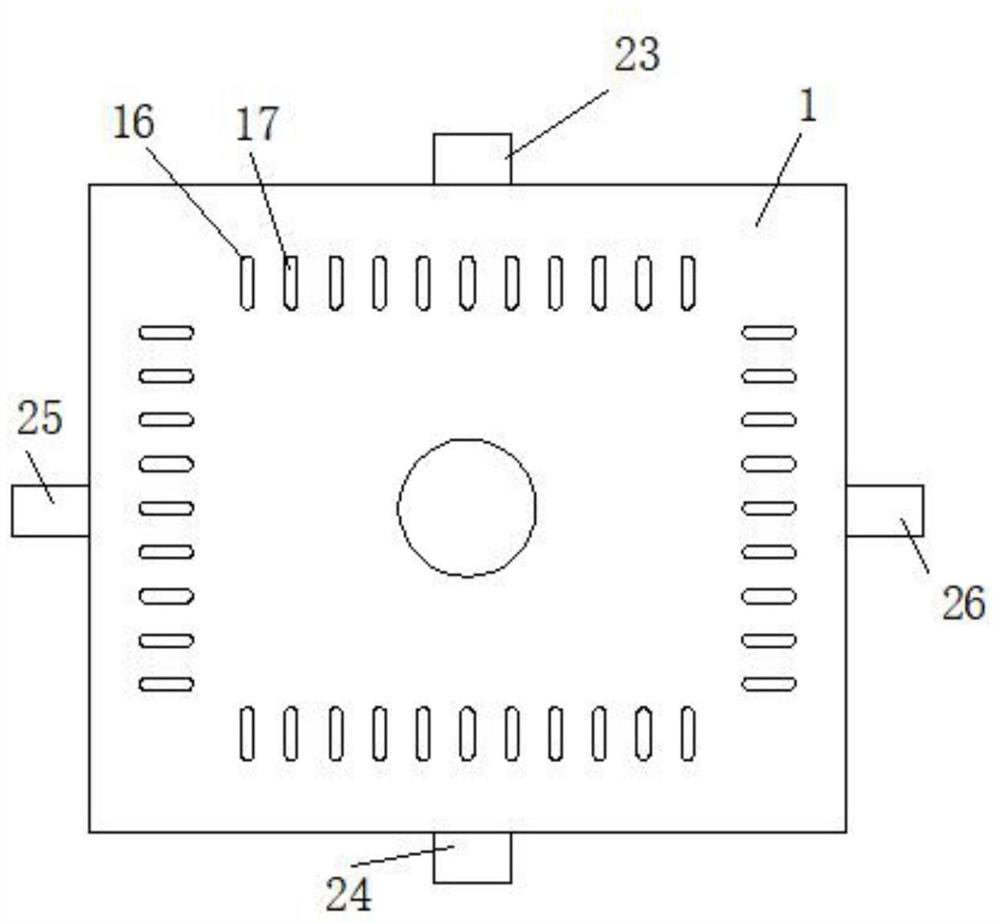

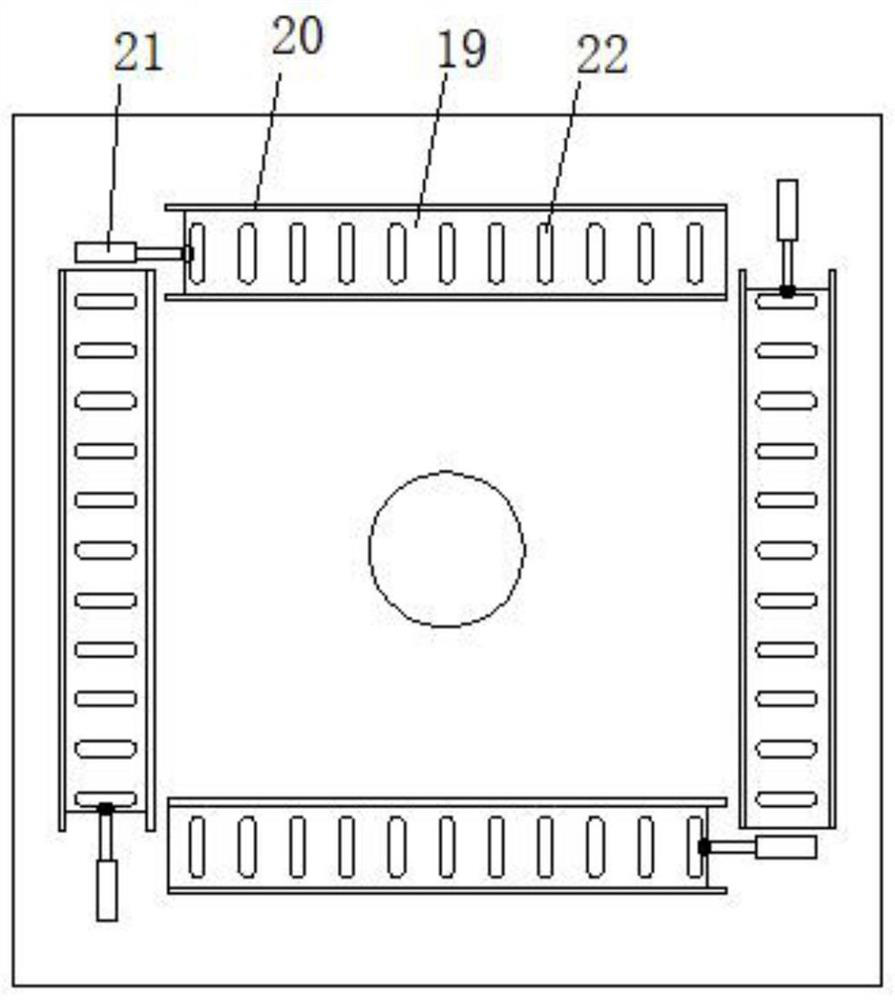

[0025] like Figure 1-5 As shown, a de-condensed temperature control system includes an outer casing 1, a dehumidifier 2, a controller 3;

[0026] The outer casing 1 is disposed in the distribution box.

[0027] The intrinsic desiccant 4 is filled in the dehumidification tank 2, the physical desiccant 4 employs one of active alumina, silica gel, activated carbon, a mineral desiccant, a molecular sieve desiccant, a clay desiccant, and the like....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com