Unmanned production operation system and method for plant factory

An operation system and plant growth technology, applied in the field of unmanned production operation methods and systems, can solve problems such as defects in information acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The inspection car 310 at least includes a first rail car and a second rail car.

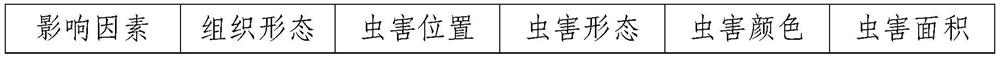

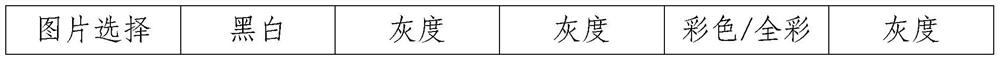

[0054] The vision module of the first rail car is provided with a black and white picture camera unit for first priority picture capture. When the first rail car moves along the track, at least the camera for identifying the growth state of the plants can be used to initially identify the growth state of the plants planted on each cultivation plate in each cultivation layer.

[0055] The vision module of the second railcar is provided with a camera unit capable of taking at least grayscale pictures. Both the first rail car and the second rail car can move on and around the cultivation frame 100 along the track, so as to ensure that the second rail car can reach the positioning position sent by the first rail car, and realize the precise positioning of plants in abnormal state. When it is recognized that there is an abnormality in the growth state of the plants growing in a certain cultiv...

Embodiment 2

[0062] This embodiment is a further improvement on Embodiment 1, and repeated content will not be repeated here.

[0063] The system is also provided with a temperature control device, which is also controlled by the data processing center 320 . When the plant is short of water or under high temperature, the leaves of the plant appear curled or turn yellow. When the first rail car finds plants in an abnormal state (for example, leaf curling) through the inspection of the first priority, the second rail car can pass the inspection of the plant in the abnormal state through the second priority. If no foreign matter is found, the data The processing center 320 considers the light, temperature or nutrient imbalance of the plants, and further feeds back to the data processing center 320 . The data processing center 320 will check the humidity, temperature, light and nutrient supply of the plant growth environment, and control the plant growth supply device 200 to adjust the enviro...

Embodiment 3

[0066] This embodiment is a further improvement on Embodiment 1 and Embodiment 2, and repeated content will not be repeated.

[0067] The cultivating frame 100 can be divided into a sowing and seedling raising area, a planting and thinning area and a growing area based on different growth stages of plants. The cultivation frame 100 in the sowing and seedling cultivation area comprises a sponge and a cultivation board. Vegetable seeds are sown on the seedling sponge block. Specifically, the seeds are sown on the sponge block, neatly placed on the cultivation board through the cultivation basket, and placed on the multi-layer seedling raising rack to raise seedlings after sowing. Before the seeds germinate, turn off the light on the seedling rack, and turn on the light after 2 days after the seeds germinate, and turn on and off the lights according to the time controller setting program. Preferably, the size of the single sponge block is 25mm×25mm×25mm. This section requires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com