Feeding manipulator of automatic winding machine for electronic transformer elements and using method

A technology for electronic transformers and automatic winding machines, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., and can solve the problems of not being able to adapt to the main body performance of the winding machine, unfavorable winding tasks for transformer components, and large deviations in placement positions. , to achieve the effect of improving winding efficiency and quality, avoiding and uncoordinated, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

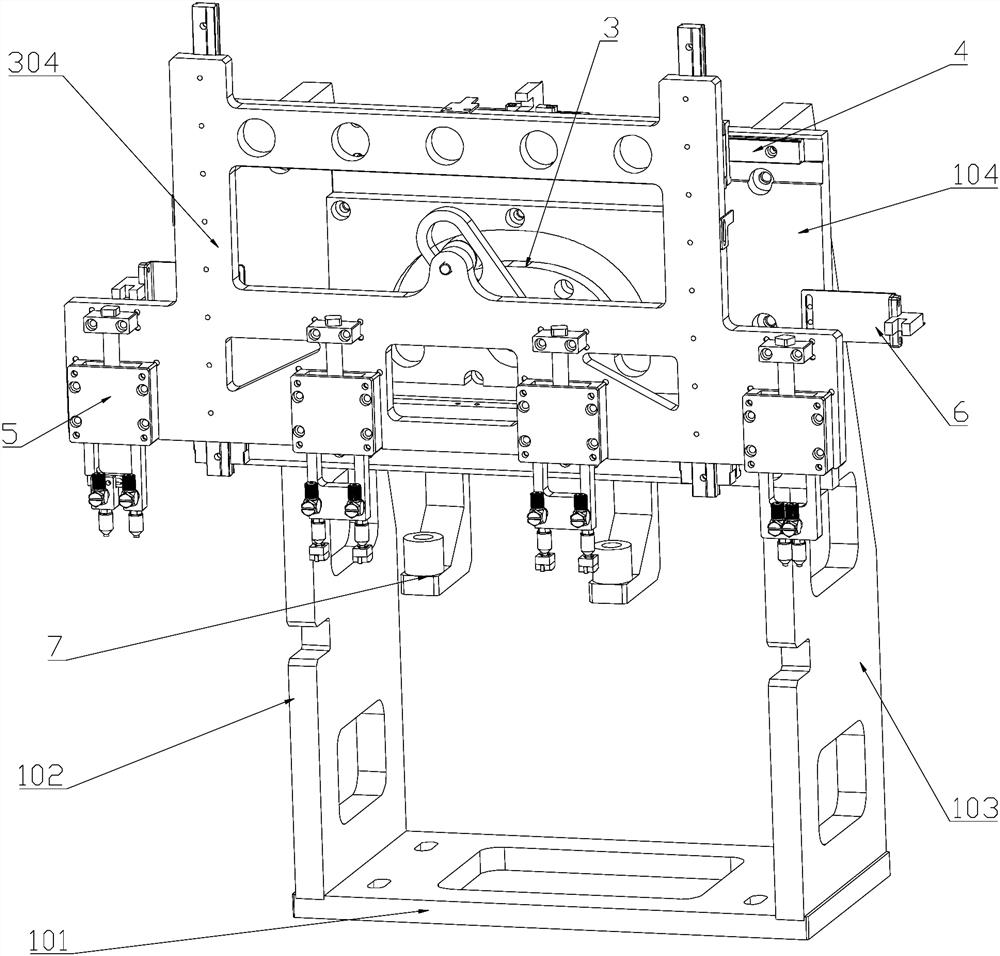

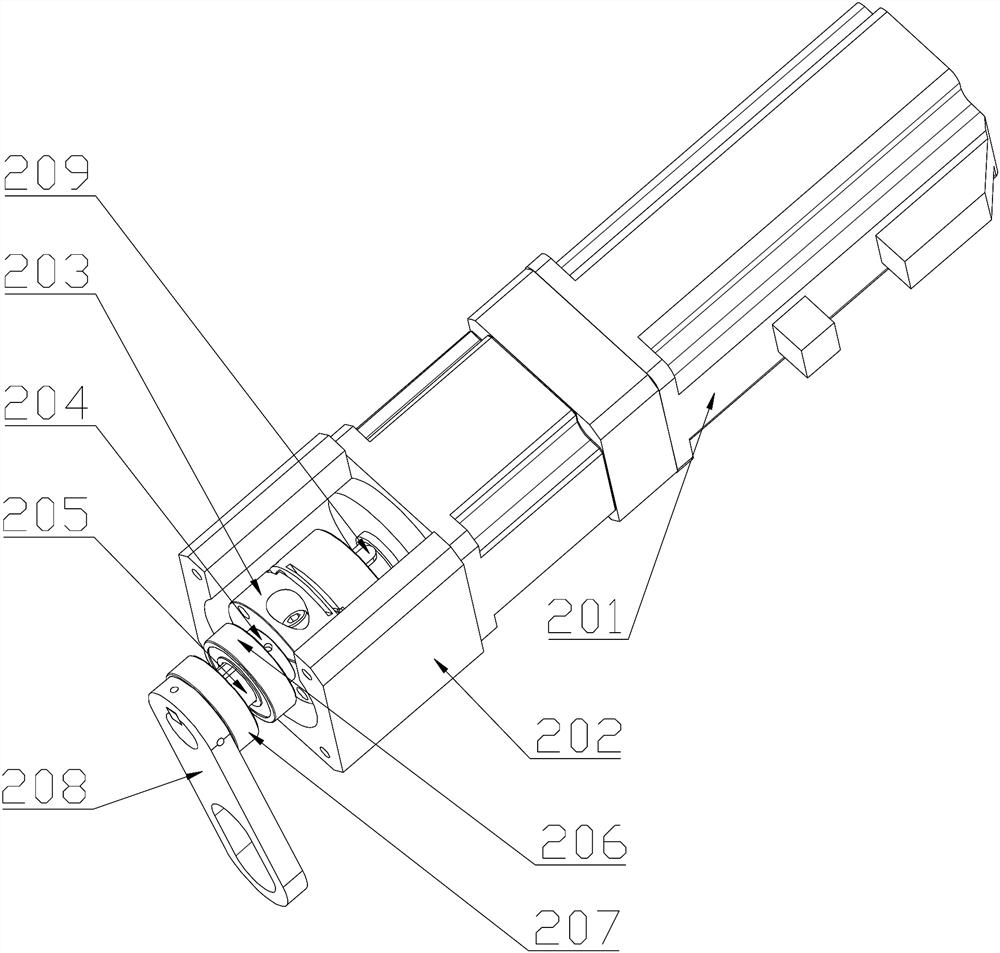

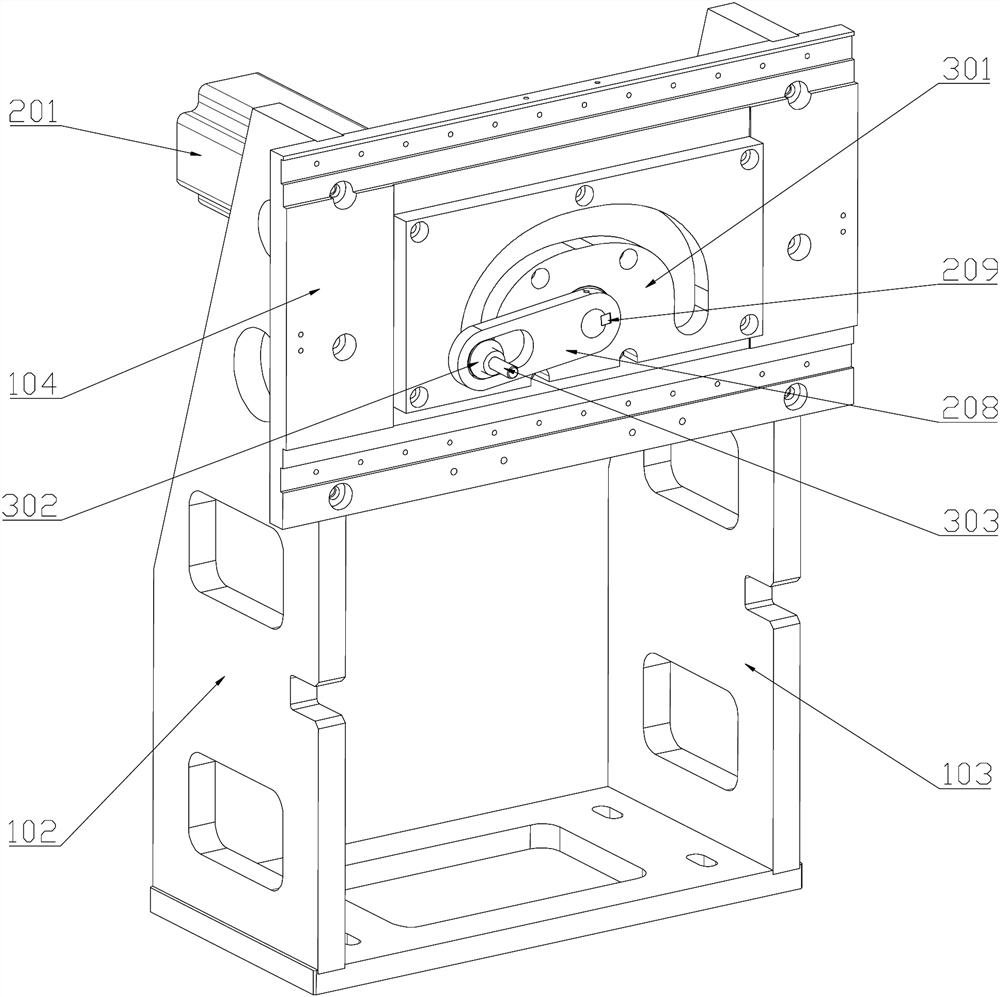

[0048] see Figure 1-9 , the feeding manipulator of the electronic transformer component automatic winding machine, which includes the power unit 2 installed on the back of the support plate 1, the power unit 2 is connected to the U-groove crank 208 through the transmission shaft 205, and the U-groove crank 208 will The power is transmitted to the cam mechanism 3 installed in front of the main mounting plate 104, the cam roller shaft 303 of the cam mechanism 3 is connected with the rotating shaft hole of the movable plate 304, and the loading execution end is driven on the guide rail slider mechanism 4 at the same time. Performing vertical motion and horizontal motion, the joint motion track formed by it is consistent with the motion track of the cam roller 302, so that the manipulator 5 installed on the loading execution end runs according to the preset motion track, and realizes automatic feeding. Through the automatic feeding manipulator with the above structure, automatic ...

Embodiment 2

[0058] The feeding manipulator of the automatic winding machine for electronic transformer components and the method of use thereof include the following steps:

[0059] Step1: When using for the first time, install the feeding manipulator correctly on the feeding station of the electronic transformer component automatic winding machine;

[0060] Step2: placing batches of electronic transformer components with winding wires at the position to be picked by the manipulator 5;

[0061] Step3: Adjust the pneumatic suction nozzle 506 of the feeding manipulator to the initial position, and then adjust the distance between the pneumatic suction nozzle 506 to an appropriate distance;

[0062] Step4: Start the power unit 2, the servo motor drives the transmission shaft 201 to rotate, the U-groove crank connected to the transmission shaft 205 drives the cam mechanism to move along the cam contour; the cam roller shaft drives the movable plate and the manipulator on it according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com