Energy-saving and low-pollution geological core cutting machine

A cutting machine, low-polluting technology, applied in the preparation of test samples, stone processing equipment, instruments, etc., can solve the problems of labor-intensive, easy to shift, inconvenient feeding, etc., to improve efficiency and effect, friction force Great, supportive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

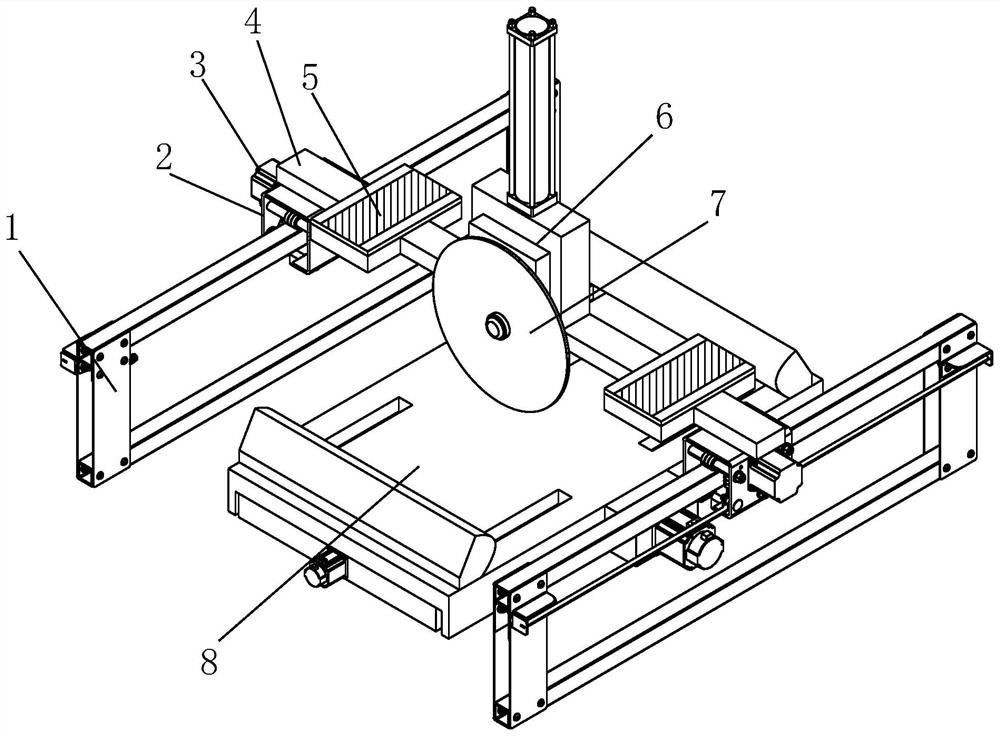

[0030] see figure 1 , the present invention provides an energy-saving and low-pollution geological core cutting machine through improvement, including a support 1, and the support 1 is provided with two groups. The first motor 3, the top of the mobile device main body 2 is provided with a crossbar 4, the two ends of the crossbar 4 are provided with a dust suction device main body 5, the middle part of the crossbar 4 is equipped with a drive adjustment device main body 6, and the front end of the drive adjustment device main body 6 is provided with The cutting blade 7 is provided with an auxiliary device 8 below the cutting blade 7 .

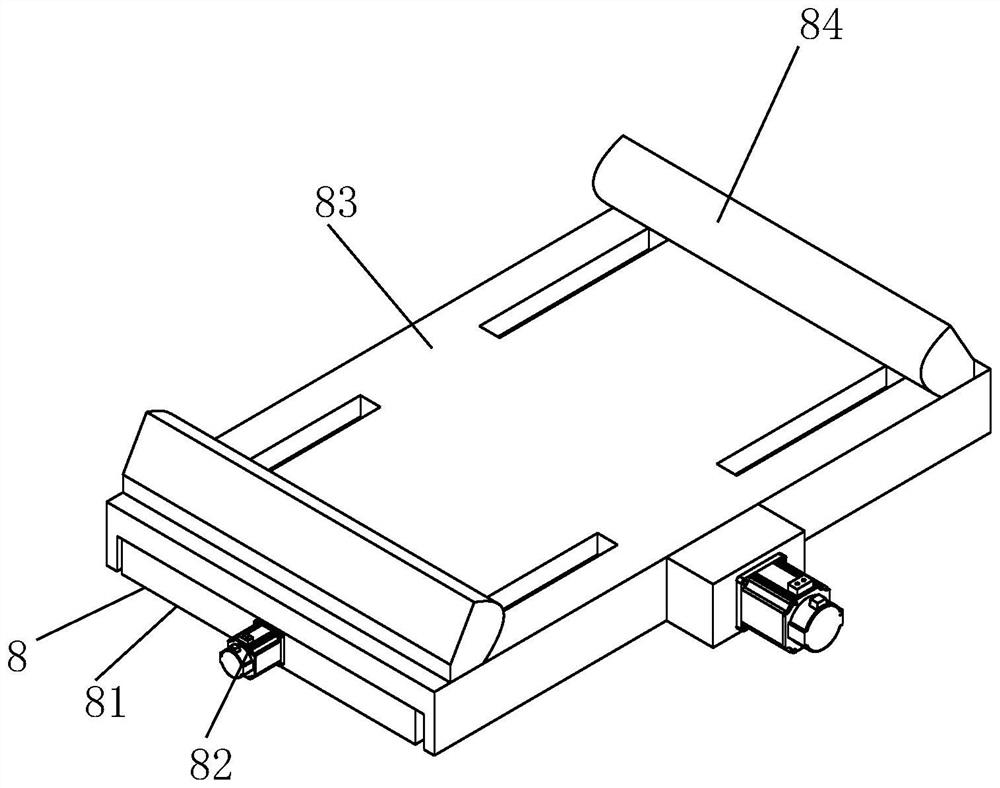

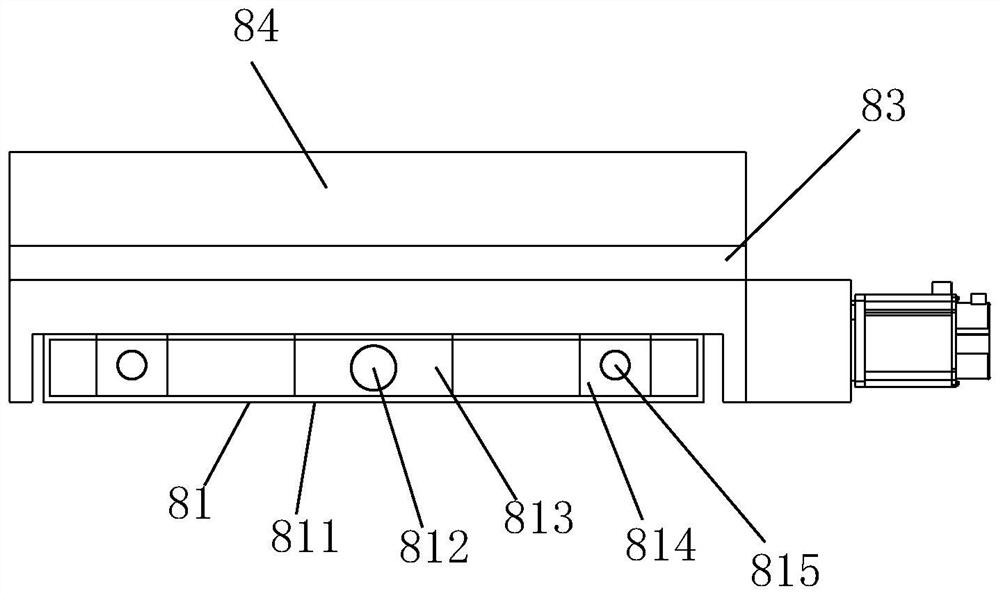

[0031] see figure 2 The present invention provides an energy-saving and low-pollution geological core cutting machine through improvement. The auxiliary device 8 includes an adjustment mechanism 81, a second motor 82, a drive mechanism 83 and a contact mechanism 84. The middle part of the front end of the adjustment mechanism 81 is provided wit...

Embodiment 2

[0037] The present invention provides an energy-saving and low-pollution geological core cutting machine through improvement. The lower ends of the left and right sides of the drive box 831 are protruding, and the bottom of the protruding position is level with the bottom of the transmission box 811, which is convenient for sliding back and forth. The ground is supported stably; the top of the transmission box 811 is open, which is convenient for driving the drive box 831 to move back and forth stably; the guide grooves 832 at the front and rear positions are not connected, so that the moving position can be stably limited.

[0038] The present invention provides an energy-saving and low-pollution geological core cutting machine through improvement, and its working principle is as follows;

[0039] First, when it is necessary to use the geological core cutting machine, first place it in the position where it needs to be used, and the position must be horizontal;

[0040] Secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com