Digital railway vehicle cab framework

A rail vehicle and driver's cab technology, applied in the field of the skeleton structure of the digital rail vehicle driver's cab, can solve the problems that the bearing capacity is not applicable, and can not meet the bearing and performance at the same time, and achieves the effects of easy replacement, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be explained below in conjunction with the accompanying drawings.

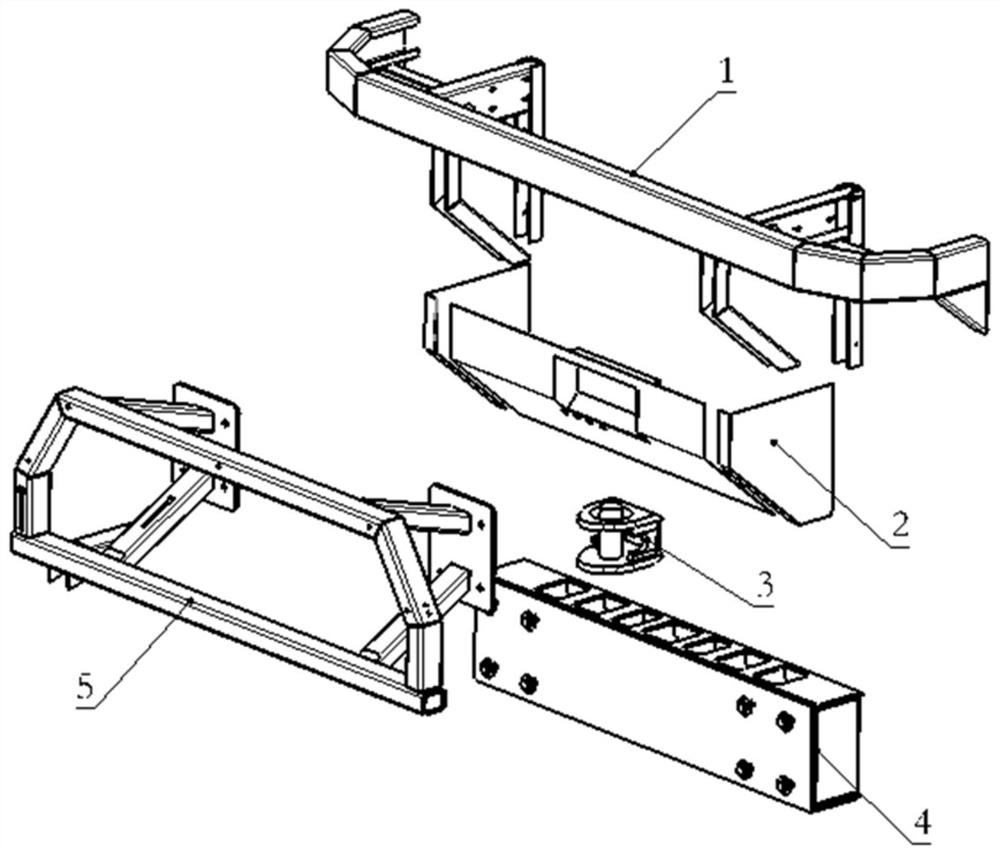

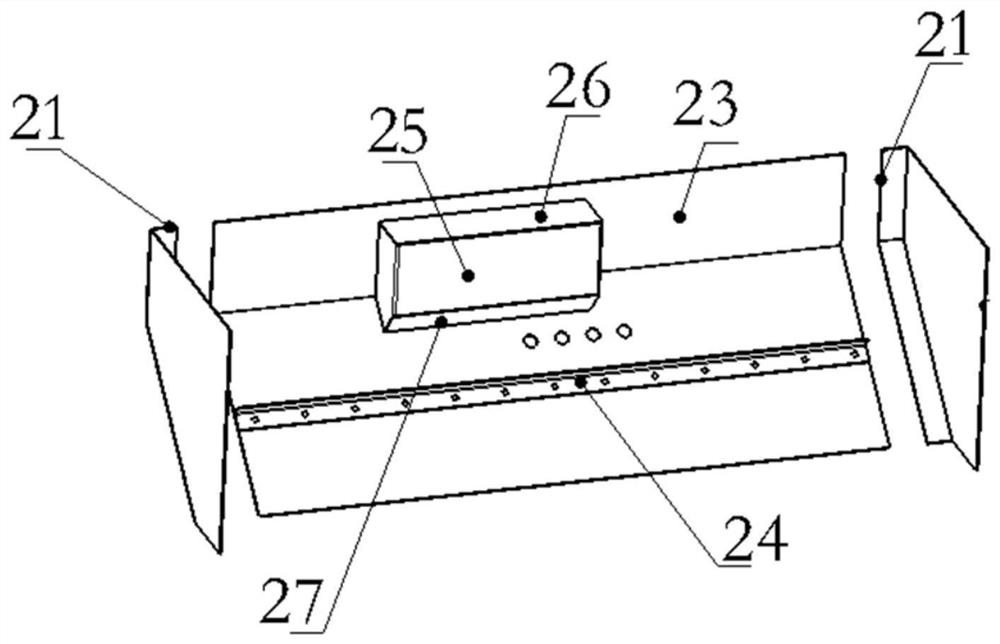

[0027] Such as figure 1 , Figure 7 As shown, it is composed of the front end frame 1, the cab sealing structure 2, the connecting seat 3, the coupler mounting base 4, and the anti-collision device 5. The coupler mounting base 4 and the anti-collision device 5 are fixedly connected by bolts, and the material of its structural parts is 2.5 Use Q310NQL2 below mm, use Q345NQR2 above 2.5mm, and connect other parts by welding (all welding in this article is inert gas shielded welding). The sealing structure 2 of the driver's cab is welded and fixed to the front end frame 1 to form a sealed overall structure at the front. The anti-collision device 5 is fixed to the front part of the coupler mounting seat 4 by bolts.

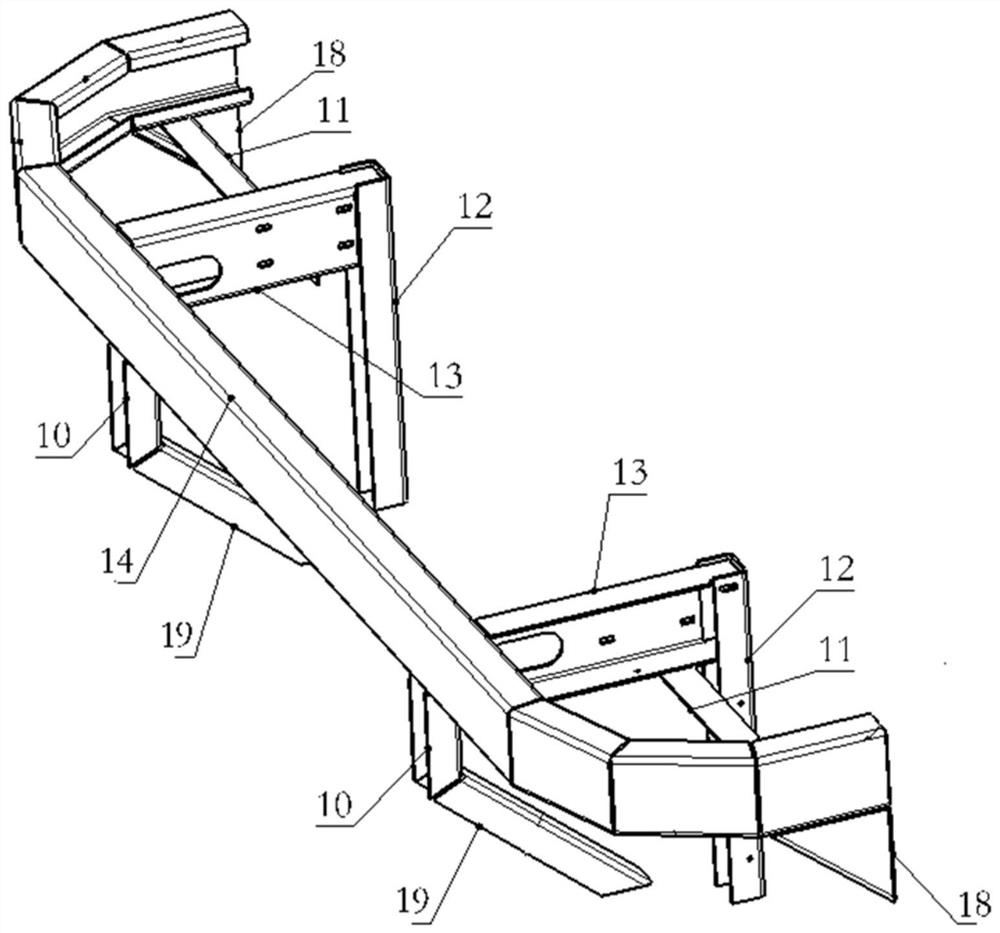

[0028] Such as figure 2 As shown, the front end frame 1 includes a U-shaped driver's cab frame 14 arranged in a horizontal direction, and two suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com