Turntable bearing type organic sewage treatment method based on triboelectrification

A triboelectric, organic sewage technology, applied in electrochemical water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low efficiency and high cost, reduce costs and reduce pollution , the effect of good practical and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

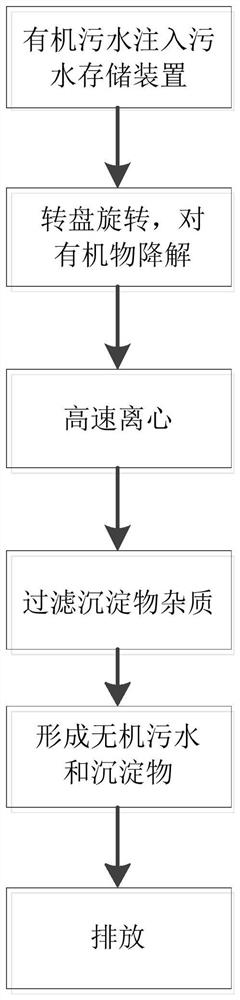

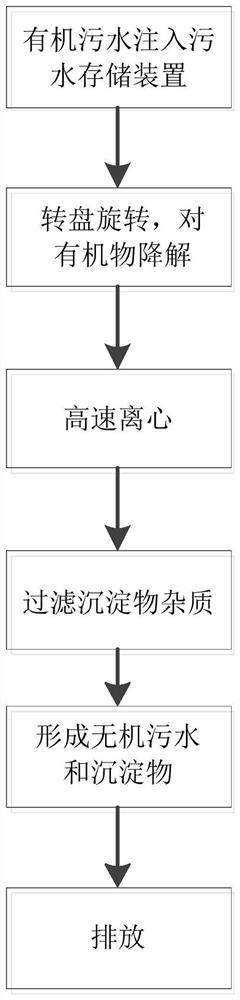

[0021] This embodiment discloses a turntable bearing type organic sewage treatment method based on friction electrification, the method is:

[0022] The sewage storage device is used to store sewage. A friction electrification device is installed in the sewage storage device. The surface of the turntable of the friction electrification device is attached with a dielectric material. The external motor drives the turntable to rotate and rubs against the metal surface below the turntable. The turntable rotates and degrades, performs high-speed centrifugation, and introduces polarized charges on the surface with the help of triboelectric effect. The charges contact with organic sewage to generate free radicals, and use the strong oxidation of free radicals to degrade organic matter in organic sewage, filter impurities, and separate them into inorganic Sewage and sediment, the infinite sewage is discharged to realize the harmless treatment of organic sewage.

[0023] The sewage sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com