Preparation method of self-compacting concrete based on compressible stacking model

A self-compacting concrete and concrete technology, which is applied in the field of concrete, can solve the problems of large creep, high heat of hydration, and aggravating environmental pollution, and achieve the effects of easy operation, reducing the amount of cementitious materials, and ensuring fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: a method for preparing self-compacting concrete based on a compressible packing model disclosed by the present invention, comprising the following steps,

[0021] S1 Determine the volume ratio of cementitious material and aggregate according to the performance parameters of concrete and the compressible packing model;

[0022] S2 Determine the dosage of each component in the raw material of the concrete according to the water-binder ratio and the predetermined theoretical dosage of the cementitious material;

[0023] S3 Stir and mix each component in the raw material of the concrete according to the dosage of S2 to obtain concrete;

[0024] Among them, concrete includes cement, fly ash, mineral powder, and aggregates composed of fine aggregate and coarse aggregate.

Embodiment 2

[0025] Embodiment 2: a method for preparing self-compacting concrete based on a compressible packing model disclosed by the present invention, the difference from Embodiment 1 is that the specific implementation of S1 is as follows,

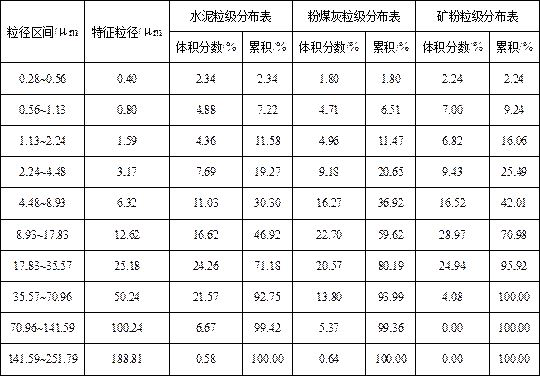

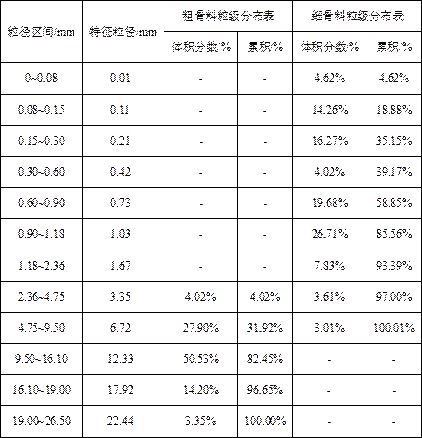

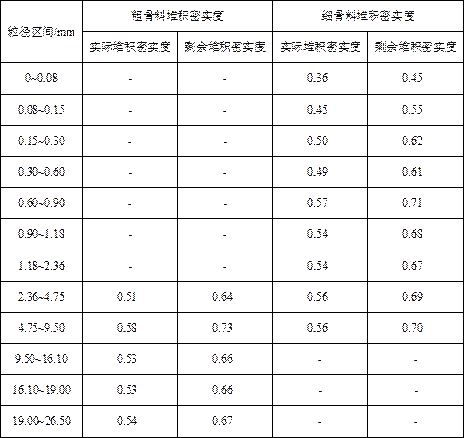

[0026] S11 Collect the performance parameters of cementitious materials and components in the aggregate, the performance parameters include density, particle size distribution and particle size volume fraction; specifically, use the pycnometer drainage method to measure cement, fly ash, mineral powder, fine The density of aggregate and coarse aggregate, the measurement results are shown in Table 1; the particle size distribution of cement, fly ash, slag, fine aggregate and coarse aggregate was measured by laser particle size analyzer, and the standard vibrating screen was used to sieve Measure the particle size volume fraction of cement, fly ash, mineral powder, fine aggregate and coarse aggregate, and the measurement results are shown in Table 2 ...

Embodiment 3

[0039] Embodiment 3: a method for preparing self-compacting concrete based on a compressible packing model disclosed in the present invention, the difference from Embodiment 1 is that the specific implementation of S2 is as follows,

[0040] S21 Determine the volume ratio of water to cementitious material according to the predetermined compressive strength of concrete and the packing density of cementitious material, that is, the water-cement ratio is (1.12~1.33):1;

[0041] S22 According to the requirements of Green CC concrete, determine the theoretical dosage of cementitious material to be 320~370kg / m³, and then determine the volume of cementitious material, water and aggregate in order in combination with the water-binder ratio, and then determine the cementitious material, water and aggregate The dosage of each component in

[0042]S23 Determine the dosage of the water reducing agent according to the dosage of the gelling material, wherein the dosage of the water reducing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump spread | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com