Ultra-early-strength high-ductility low-shrinkage mortar and preparation method thereof

A technology with high ductility and low shrinkage, applied in the field of fiber-reinforced cement-based composite materials, can solve problems such as low early strength, lack of advantages, and durability problems, and achieve the goals of improving early strength, optimizing service performance, and optimizing particle gradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

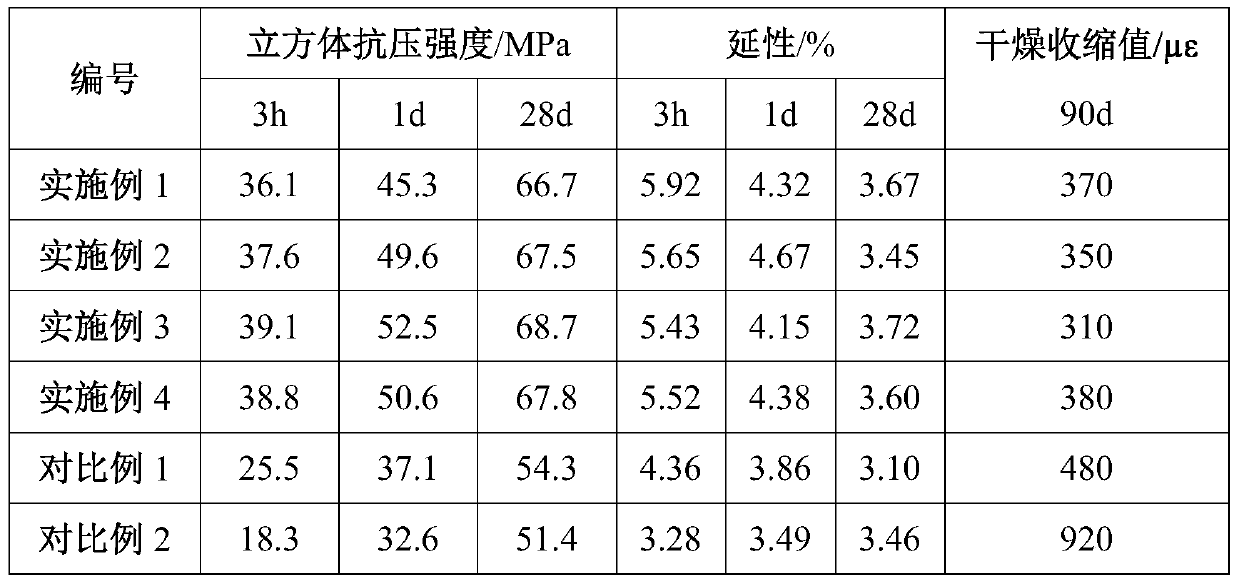

Embodiment 1

[0021] Super early strength, high ductility and low shrinkage mortar includes the following components by weight: 60 parts of sulfoaluminate cement, 4 parts of Portland cement, 24 parts of fly ash, 32 parts of fine aggregate, 20 parts of water, polyethylene 1.9 parts of alcohol fiber, 0.6 parts of polycarboxylate water reducer.

[0022] Concrete preparation method comprises the following steps:

[0023] Step 1, dissolving polycarboxylate water reducer in water, adding predispersed polyvinyl alcohol fibers to form a mixture;

[0024] Step 2, weighing each component according to parts by weight, dry mixing sulphoaluminate cement, Portland cement, fly ash and fine aggregate at a speed of 140r / min for 2min;

[0025] Step 3, slowly add 80wt% of water in which all the water reducer is dissolved, and wet stir at a speed of 190r / min for 3min to form a uniform slurry;

[0026] Step 4: Finally, add the remaining 20wt% of the water in which the polycarboxylate-based water reducer is di...

Embodiment 2

[0028] Super early strength, high ductility and low shrinkage mortar includes the following components in parts by weight: 64 parts of sulfoaluminate cement, 8 parts of Portland cement, 28 parts of fly ash, 28 parts of fine aggregate, 18 parts of water, polyethylene 1.6 parts of alcohol fiber, 0.75 parts of polycarboxylate water reducer.

[0029] Concrete preparation method comprises the following steps:

[0030] Step 1, dissolving polycarboxylate water reducer in water, adding predispersed polyvinyl alcohol fibers to form a mixture;

[0031] Step 2, weighing each component according to parts by weight, dry mixing sulphoaluminate cement, Portland cement, fly ash and fine aggregate at a speed of 150r / min for 4min;

[0032] Step 3, slowly add 85wt% of water dissolved in polycarboxylate-based water reducer, and wet stir for 5 minutes at a speed of 185r / min to form a uniform slurry;

[0033] Step 4: Finally, add the remaining 15wt% of the water in which the polycarboxylate-based...

Embodiment 3

[0035] Super early strength, high ductility and low shrinkage mortar includes the following components in parts by weight: 76 parts of sulfoaluminate cement, 10 parts of Portland cement, 20 parts of fly ash, 31 parts of fine aggregate, 22 parts of water, polyethylene 1.8 parts of alcohol fiber, 0.5 parts of polycarboxylate water reducer.

[0036] Concrete preparation method comprises the following steps:

[0037] Step 1, dissolving polycarboxylate water reducer in water, adding predispersed polyvinyl alcohol fibers to form a mixture;

[0038] Step 2, weighing each component according to parts by weight, dry mixing sulphoaluminate cement, Portland cement, fly ash and fine aggregate at a speed of 140r / min for 2min;

[0039] Step 3, slowly add 88wt% of water dissolved in polycarboxylate-based water reducer, and wet stir for 5 minutes at a speed of 185r / min to form a uniform slurry;

[0040] Step 4: Finally, add the remaining 12wt% of the water in which the polycarboxylate-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com