A transparency modifier for vapor phase antirust film

A gas-phase anti-rust and modifier technology, applied in the field of transparency modifier, can solve the problems of unevenness, abnormal color of anti-rust film, and reduce the appearance quality of products, and achieve the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a vapor phase antirust film, the steps are as follows:

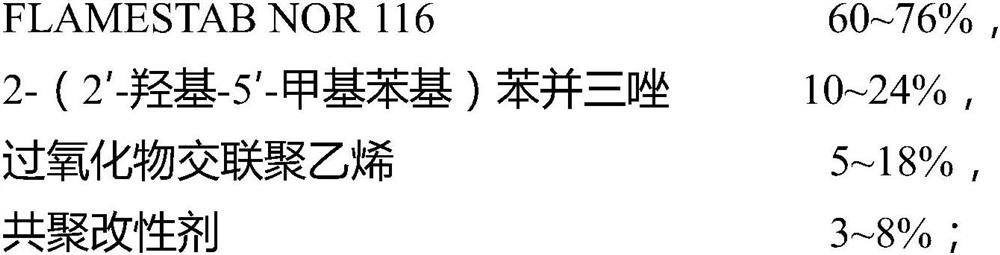

[0037] (1) Preparation of transparency modifier: according to FLAMESTAB NOR 116 60%, 2-(2'-hydroxy-5'-methylphenyl) benzotriazole 14%, peroxide cross-linked polyethylene 18%, The proportion of copolymerization modifier is 8% and the raw material is weighed, the temperature of the twin-screw extruder is set to 140°C, the above is added to it, mixed and extruded to obtain the transparency modifier;

[0038] (2) Preparation of vapor phase antirust film: according to high pressure polyethylene 2426 29%, linear polyethylene 7042 39%, metallocene polyethylene 20%, vapor phase antirust masterbatch 10%, transparency improver 2%, at a temperature of 150 ℃ Next, the raw material is placed in the blown film equipment and blown into a film with a thickness of 0.1mm.

Embodiment 2

[0040] A preparation method of a vapor phase antirust film, the steps are as follows:

[0041] (1) Preparation of transparency modifier: according to FLAMESTAB NOR 116 72%, 2-(2'-hydroxy-5'-methylphenyl) benzotriazole 10%, peroxide cross-linked polyethylene 12%, The ratio of 6% of the copolymerization modifier is to weigh the raw materials, set the temperature of the twin-screw extruder to 140°C, add the above, mix and extrude and granulate to obtain the transparency modifier;

[0042] (2) Preparation of vapor phase antirust film: according to high pressure polyethylene 2426 29%, linear polyethylene 7042 39%, metallocene polyethylene 20%, vapor phase antirust masterbatch 10%, transparency improver 2%, at a temperature of 150 ℃ Next, the raw material is placed in the blown film equipment and blown into a film with a thickness of 0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com