Electromagnetic induction heating assisted supersonic plasma spraying gun device

An electromagnetic induction heating, supersonic plasma technology, applied in induction heating devices, induction heating, coating and other directions, can solve the problems of difficult melting of high melting point powder, low spraying speed, easy burnout of nozzles, etc., to increase the spraying surface , Increase the spraying temperature and enhance the effect of the spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

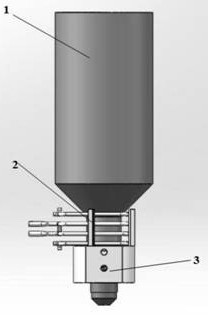

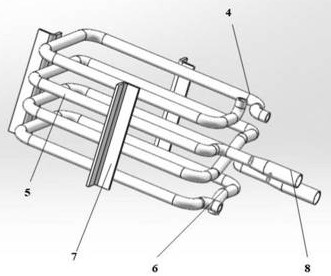

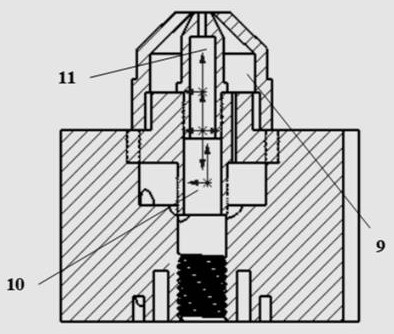

[0025] The inventive device such as figure 1 As shown, it includes a gun body 1, a rectangular coil 2 of an electromagnetic induction heating device, and a nozzle 3 with an atomizing device. The electromagnetic induction heating device includes an upper cold water pipe 4 , a rectangular heating coil 5 , a lower cold water pipe 6 , a fixing frame 7 and a wire interface 8 . The nozzle device with the atomizing device comprises an air sleeve 9 , a nozzle connector 10 and a nozzle 11 .

[0026] The working principle of the spray gun is that the tungsten cathode is connected to the gun body 1, the working gas generates a plasma arc through the tungsten cathode and the nozzle anode, and the powder is sent axially to the gun body through the powder feeding pipe, and is heated by plasma heating and electromagnetic induction heating device 2. It is heated to a molten state for the second time and reaches supersonic speed. It is atomized by the atomizing device and sprayed out from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com