Piezoelectric ultrasonic guided wave detection device and method

A piezoelectric ultrasonic and detection device technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound wave emission technology for material analysis, and instruments. , can not effectively reduce crosstalk and other problems, to achieve the effect of reducing reflection oscillation, high stability, reducing noise and harmonic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

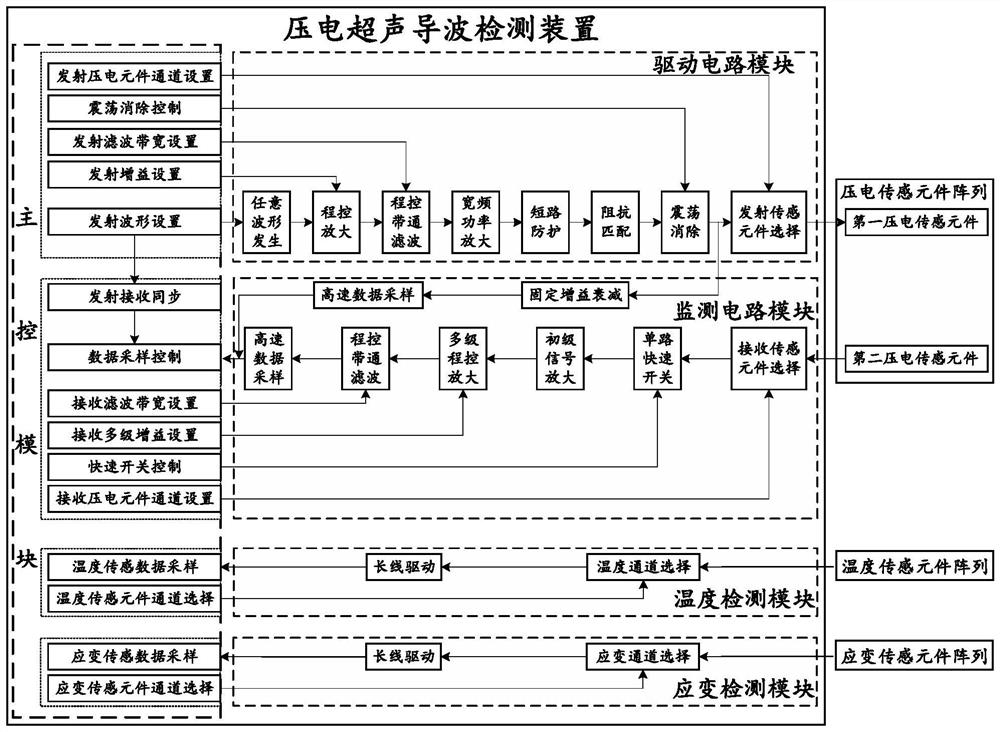

[0068] Such as figure 1 As shown, Embodiment 1 of the present invention provides a piezoelectric ultrasonic guided wave detection device, including: driving and monitoring of piezoelectric sensing elements, monitoring of temperature sensing elements and strain sensing elements.

[0069] When using piezoelectric sensing elements for structural damage monitoring, paste multiple piezoelectric sensing elements on the structure to be tested, use one piezoelectric sensing element to transmit a high-voltage driving signal, and use another piezoelectric sensing element to receive Response signal, if the structure is damaged, the response signal will carry damage information.

[0070] Therefore, the piezoelectric sensing element part mainly includes two parts: the driving circuit and the monitoring circuit, and the main control module performs overall coordinated control of all circuits of the entire instrument.

[0071] The driving part of the piezoelectric sensing element is compose...

Embodiment 2

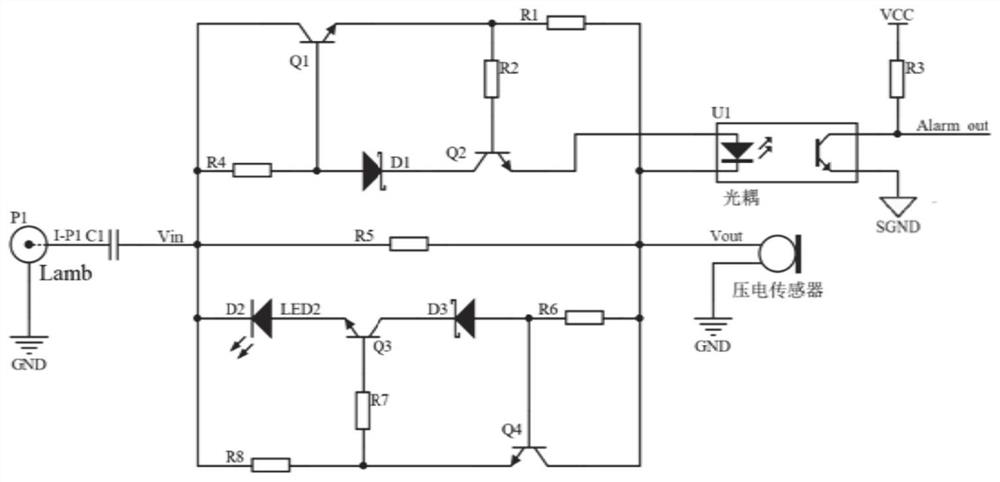

[0092] Embodiment 1 of the present invention provides a piezoelectric ultrasonic guided wave detection device, including each specific module in Embodiment 1, wherein a specific example of a short circuit protection module is given, as figure 2 shown, including:

[0093] The electrical signal input terminal Vin is connected to the signal output terminal V through the fifth resistor R5 OUT connection, signal output V OUT It is used to connect with the emitting piezoelectric sensing element, the signal input end is respectively connected with the first end of the fourth resistor R4 and the collector of the first triode Q1, and the emitter of the first triode Q1 is respectively connected with the first resistor The first end of R1 is connected to the first end of the second resistor R2, and the second end of the second resistor R2 is connected to the base of the second transistor Q2;

[0094] The second terminal of the fourth resistor R4 is respectively connected to the base o...

Embodiment 3

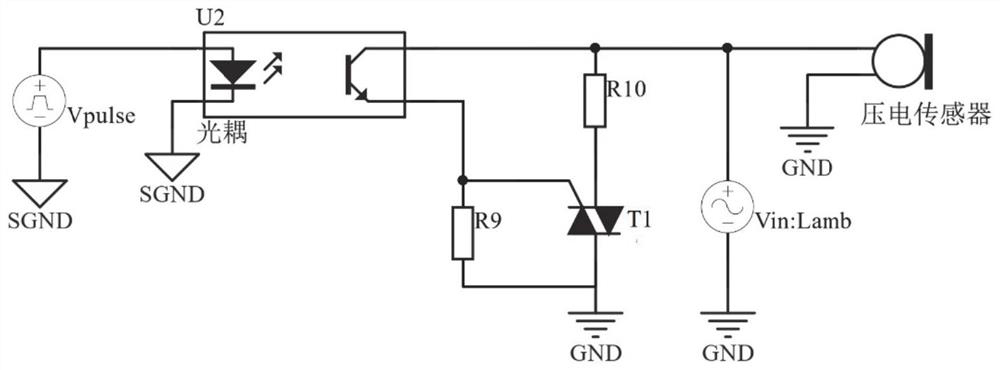

[0103] Embodiment 1 of the present invention provides a piezoelectric ultrasonic guided wave detection device, including each specific module in Embodiment 1, wherein a specific example of an oscillation elimination module is given, as image 3 shown, including:

[0104] The Lamb wave signal input terminal Vin is respectively connected to the transmitting piezoelectric sensing element, the third terminal of the second optocoupler U2, and the first terminal of the tenth resistor R10; the second terminal of the tenth resistor R10 is connected to the first terminal of the first bidirectional thyristor T1 The first end is connected, the gate of the first two-way thyristor T1 is connected to the fourth end of the second optocoupler U2, and the first end of the ninth resistor R9, the third pin of the first two-way thyristor T1 is connected to the first end of the ninth resistor R9 Both ends are grounded.

[0105] The first end of the second optocoupler is connected to the pulse inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com