High-corrosion-resistance stainless steel and manufacturing method thereof

A corrosion-resistant, stainless steel technology, applied in the field of high-corrosion-resistant stainless steel production, can solve the problem that the lid of the thermos cup is not easy to unscrew, and achieve the effect of avoiding excessive internal pressure, saving process and cost, and saving grinding steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

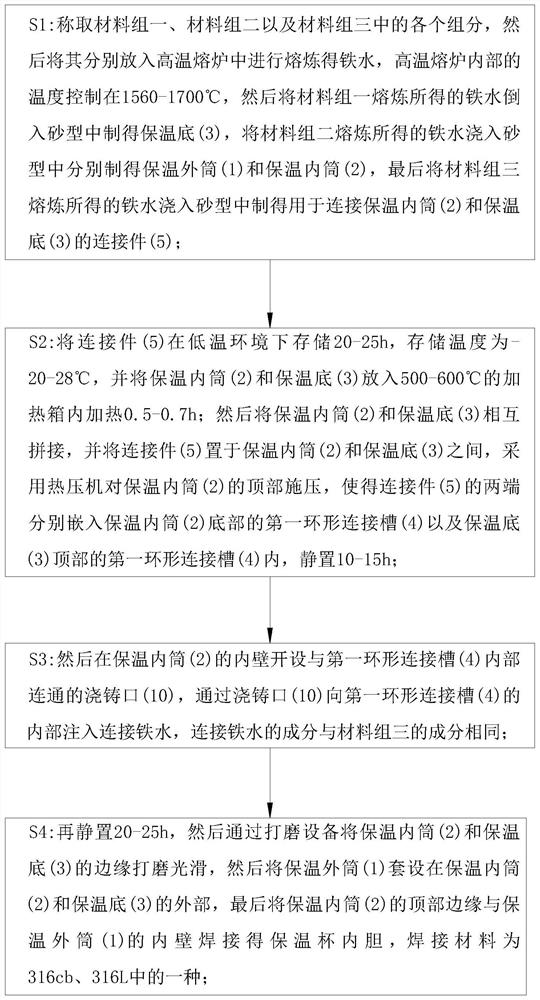

[0044] The preparation method of the corrosion-resistant stainless steel is as follows:

[0045] S1: Weigh each component in material group 1, material group 2 and material group 3, and then put them into high-temperature furnace for smelting to obtain molten iron. The temperature inside the high-temperature furnace is controlled at 1560-1700°C, and then The molten iron smelted in Group 1 is poured into the sand mold to make the insulation bottom 3, the molten iron smelted in the material group 2 is poured into the sand mold to make the insulation outer cylinder 1 and the insulation inner cylinder 2 respectively, and finally the molten iron obtained in the material group 3 is smelted Pour into the sand mold to make the connector 5 for connecting the heat preservation inner cylinder 2 and the heat preservation bottom 3;

[0046] S2: Store the connecting piece 5 in a low temperature environment for 20-25 hours, the storage temperature is -20-28°C, and put the insulation inner cy...

Embodiment approach

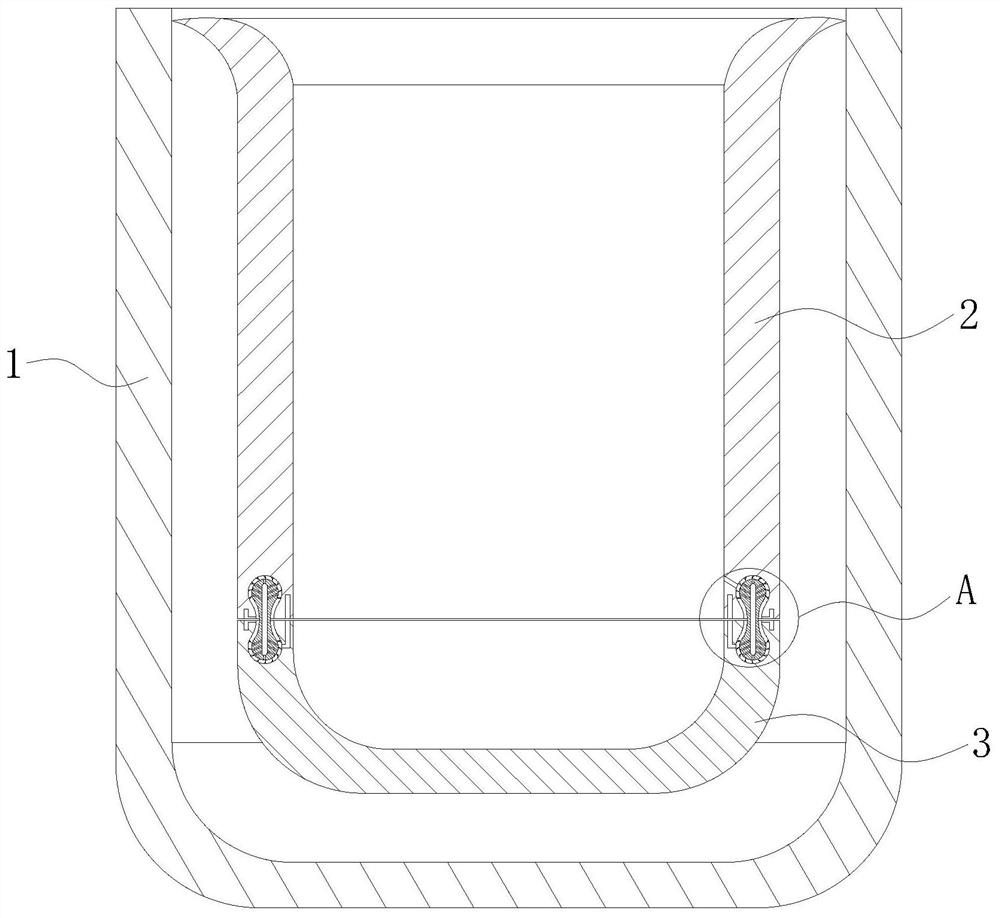

[0052] As an embodiment of the present invention, the inner wall of the first annular connecting groove 4 is evenly provided with raised thorns 11; the raised thorns 11 are composed of material group three; The connected molten iron will be integrally formed with the protruding thorns 11 on the inner wall of the first annular connecting groove 4 when it is solidified, so that the connection between the molten iron and the inner wall of the first annular connecting groove 4 is more firmly connected, further increasing the size of the first annular connection. The connection strength and pull-out resistance of the connecting groove 4 and the connecting piece 5.

[0053] As an embodiment of the present invention, the bottom edge of the thermal insulation inner cylinder 2 and the top edge of the thermal insulation bottom 3 are provided with a second annular connection groove 8 communicating with two sets of first annular connection grooves 4; The cross-section of the annular conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com