Fixing method for exterior wall insulation board

A technology of external wall thermal insulation board and fixing method, which is applied in thermal insulation, processing of building materials, building components, etc., can solve the problems of difficult quality control, hidden leakage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

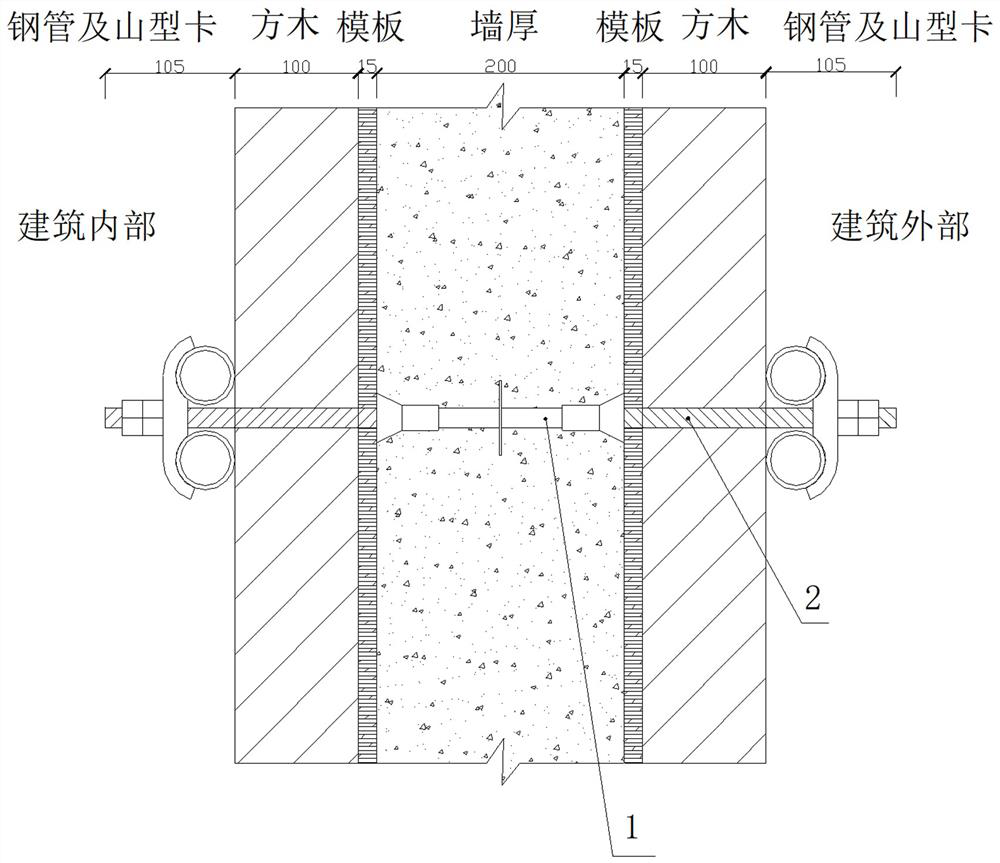

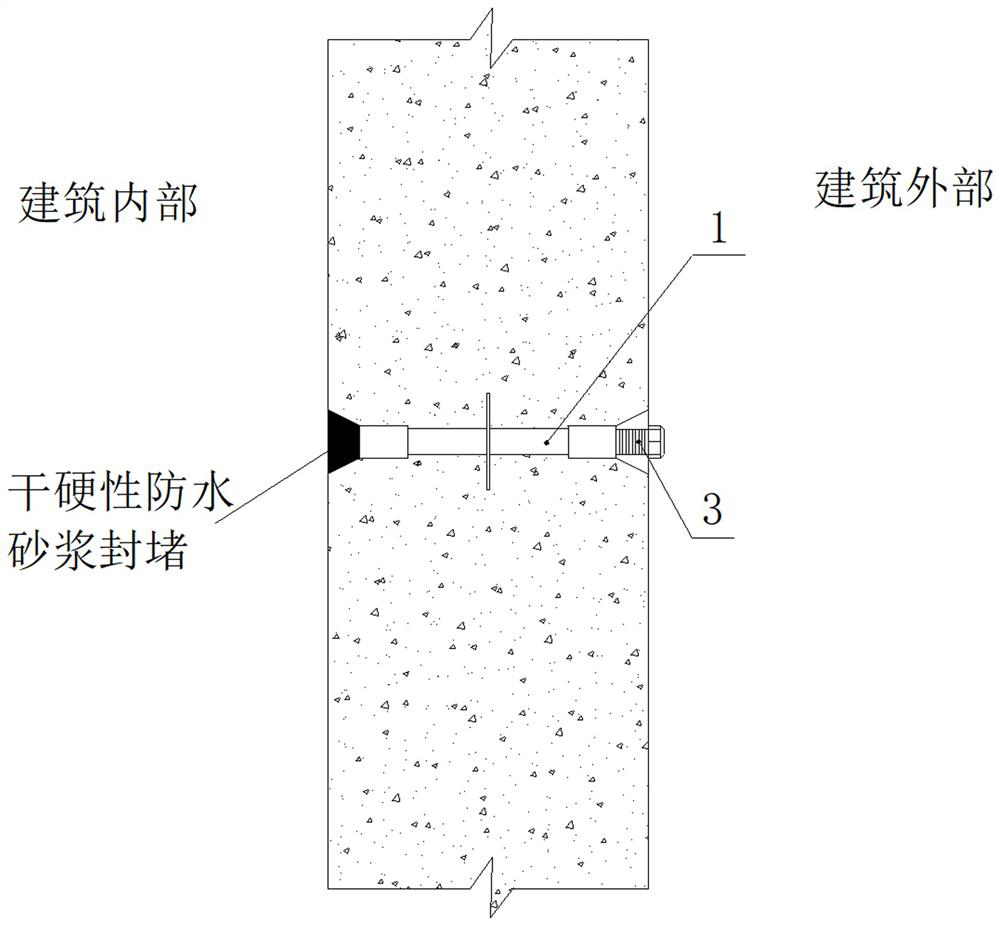

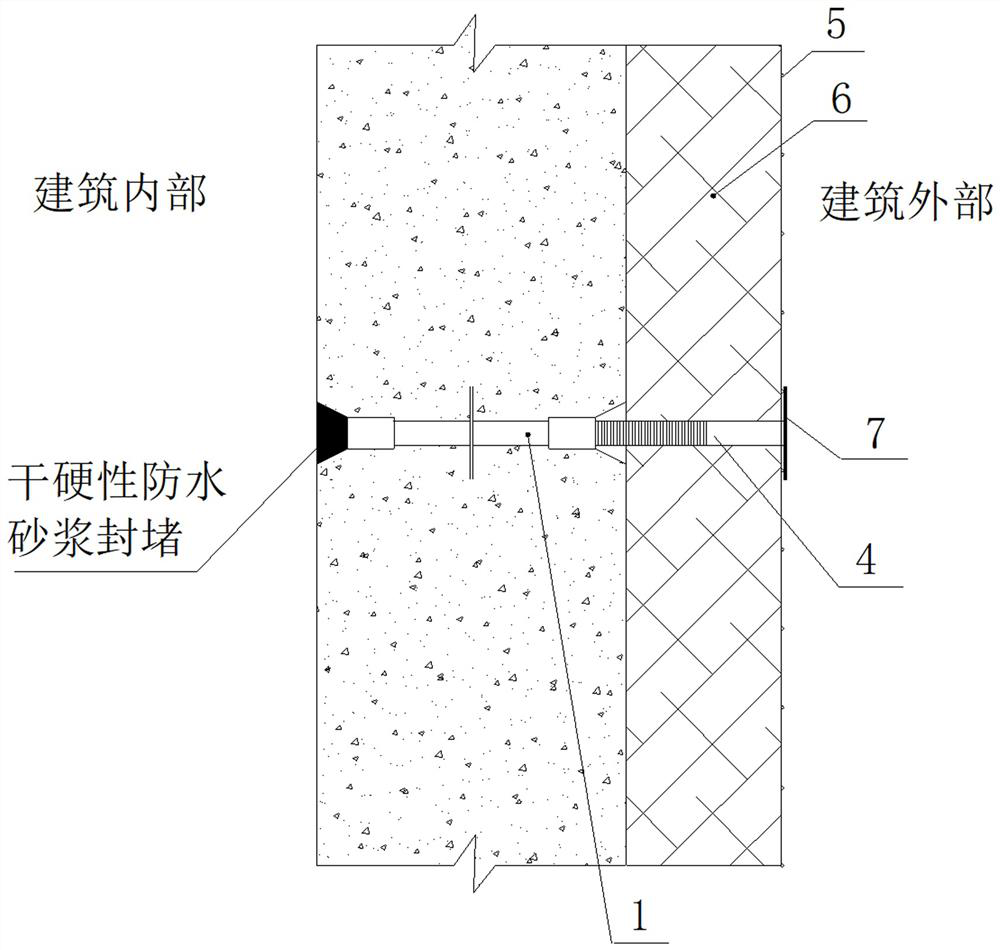

[0020] Such as Figure 1 to Figure 3 As shown, a method for fixing an external wall insulation board includes the following steps: Step 1: Processing of the external wall formwork and pouring of concrete in the main construction stage: the external wall formwork is fixed with a three-stage water-stop screw 1, and the external wall is placed to prevent water seepage The occurrence of the phenomenon; the specific operation is as follows: first, process the exterior wall formwork according to the design size, and open a number of through holes at the set position for the movable screw rod 2 to pass through, and then place the exterior wall formwork at the set position, The three-section water-stop screw 1 is placed between two exterior wall templates, the two ends of the three-section water-stop screw 1 are threaded with the movable screw rod 2, and the two ends of the two movable screw rods 2 pass through the through hole and are located The outside of the exterior wall formwork...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap