Fair-faced concrete formwork splicing and reinforcing method

A technology for assembly of fair-faced concrete and formwork, which is applied to formwork/formwork components, formwork/formwork/work frame connectors, and on-site preparation of building components, which can solve the problem of high construction requirements and difficult finalization , integration and other issues, to achieve the effect of simple assembly, reduced investment in equipment rental, and reduced template displacement and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

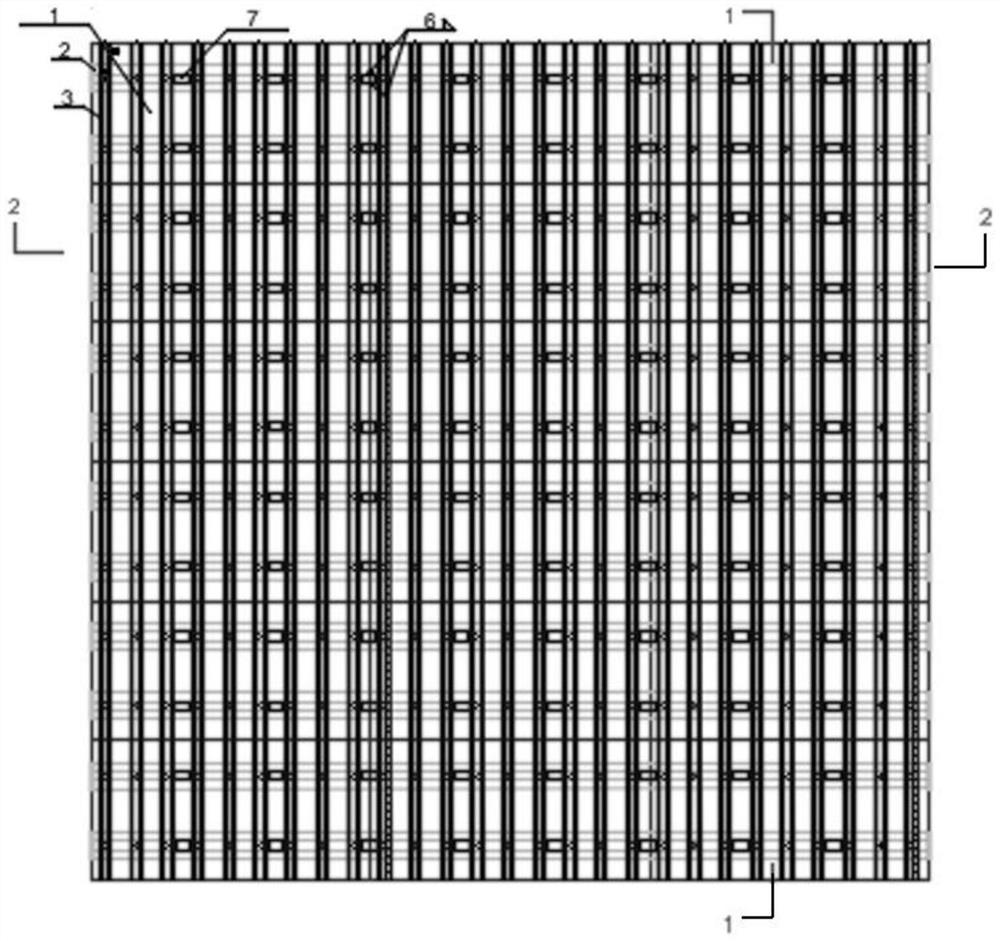

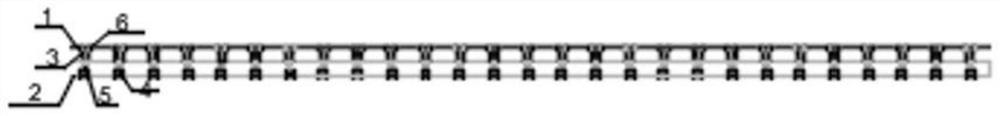

[0051] Such as Figure 1-3 As shown, it shows a kind of assembly and reinforcement effect of fair-faced concrete formwork, including fair-faced concrete formwork 1, channel steel 2, several-shaped steel 3, connectors 4, ordinary bolts 5, self-tapping bolts 6, and channel steel 2. Part 4 is welded and connected. Self-tapping screw holes and ordinary bolt holes are reserved on the several-character steel 3 for installing self-tapping bolts 6 and ordinary bolts 5 respectively. The double channel steel 2 is placed horizontally on the assembly table. The steel 3 and the double channel steel 2 are vertically placed, and the fair-faced concrete formwork 1 is placed on the several-character steel 3, and the clear-faced concrete formwork 1 is bonded with silicone structural sealant.

[0052] In this embodiment, the connector 4 is a steel plate.

Embodiment 2

[0054] A method for assembling and strengthening fair-faced concrete formwork, comprising the following steps:

[0055] S1, prepare fair-faced concrete formwork;

[0056]S2. Make double channel steel, and the channel steel is welded and connected by connectors;

[0057] S3. Processing a few-shaped steel, reserving self-tapping screw holes and ordinary bolt holes;

[0058] S4. Place the double channel steel horizontally on the assembly table, and adjust the distance between the double channel steel;

[0059] S5, vertically place the several-character steel and the double channel steel;

[0060] S6. Place the fair-faced concrete formwork on the several-shaped steel, and perform preliminary assembly, and use a ruler to check that the formwork flatness is ≤ 3mm;

[0061] S7. Remove the fair-faced concrete formwork, and tighten the double channel steel and the several-shaped steel through bolts for reinforcement;

[0062] S8. Reinstall the fair-faced concrete formwork, check an...

Embodiment 3

[0069] In a specific embodiment, a method for assembling and strengthening fair-faced concrete formwork also includes the following steps:

[0070] Step 1. Use 15mm thick high-quality clear-water special-coated formwork (fair-faced concrete formwork) and wood-grain clear-water panels. The template is divided into 900*1800mm, and the size of the clear water panel is 915*1830*15mm. Check that there are no cracks and moires on the surface of the formwork, the surface coating layer is thick and uniform, smooth and smooth, and has good wear resistance;

[0071] Step 2, making double channel steel, between the channel steel, welded connection with connector 1, the distance between the connectors is 600mm;

[0072] Step 3: Process Jizi steel according to the diagram of the fair-faced concrete formwork system, in which the self-tapping screw hole diameter is φ5, and the hole spacing is 50mm. The hole diameter of common bolts is φ20, and the hole spacing is 450mm;

[0073] Step 4. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com