Water-cooling bearing box end cover with good sealing effect

A water-cooled bearing and sealing effect technology, applied in the field of bearing cooling, can solve the problems of the bearing box and the end cover being installed tightly, the bearing box installation workload is large, and the installation parts are many, etc., so as to achieve convenient and fast installation and good heat dissipation effect. , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

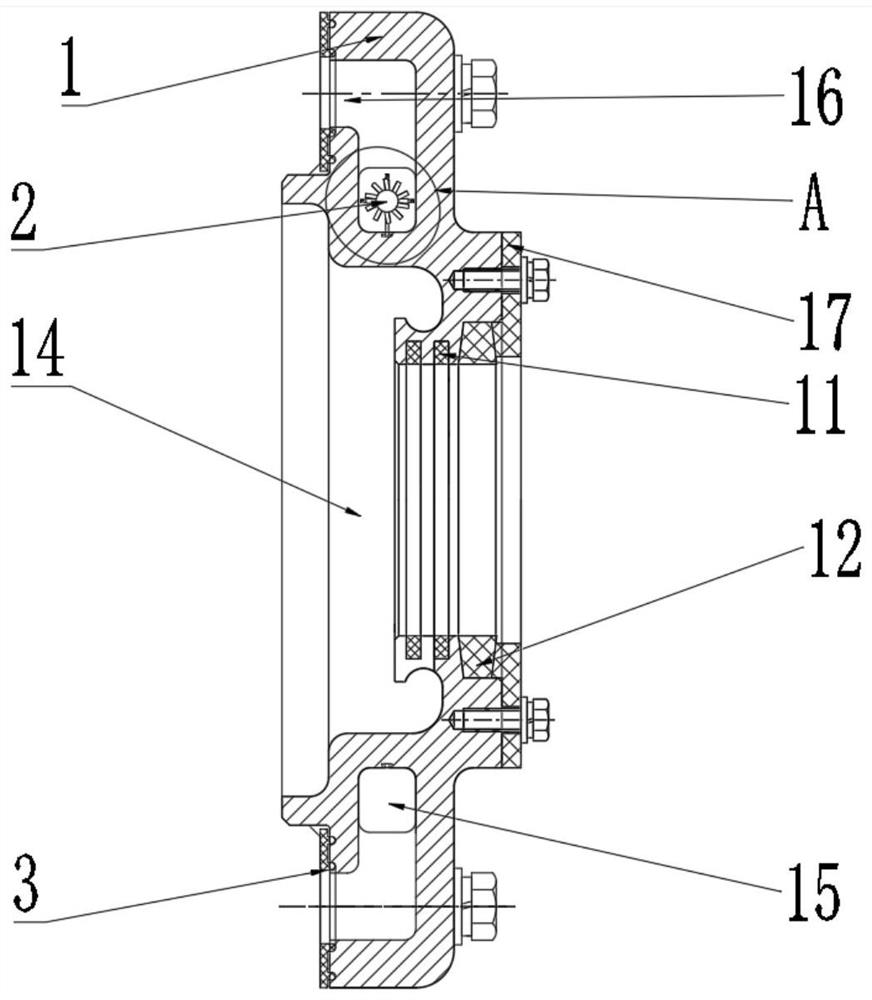

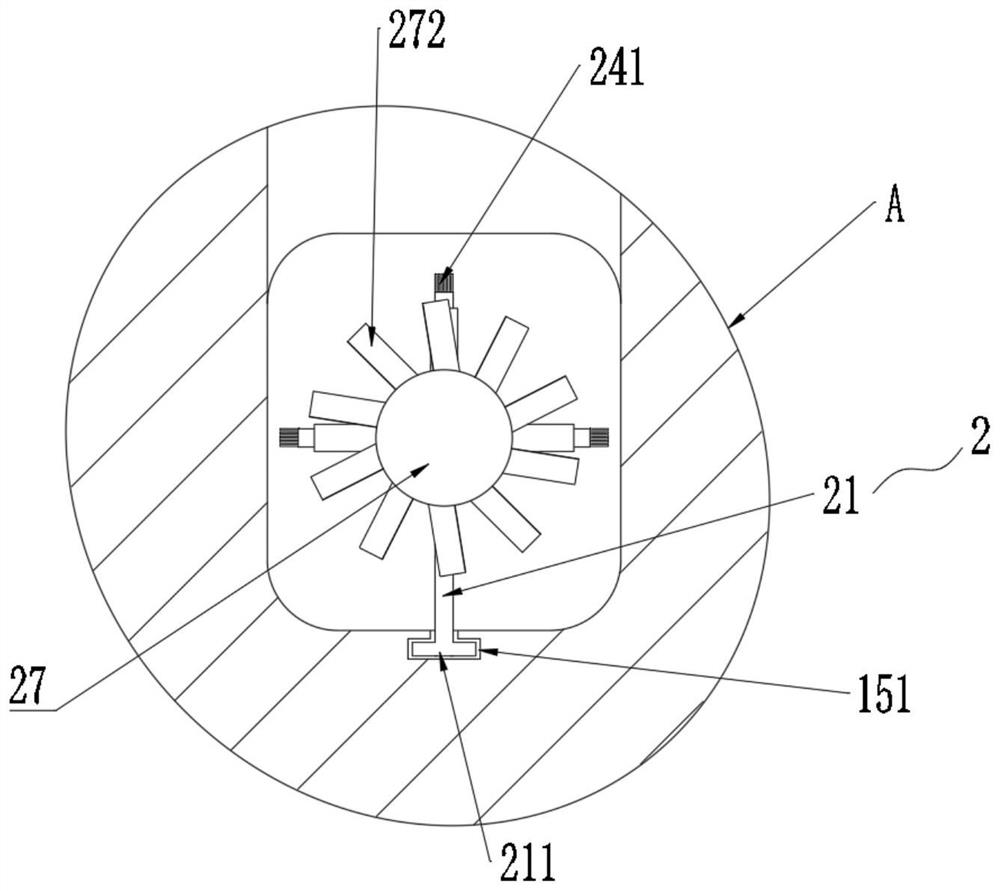

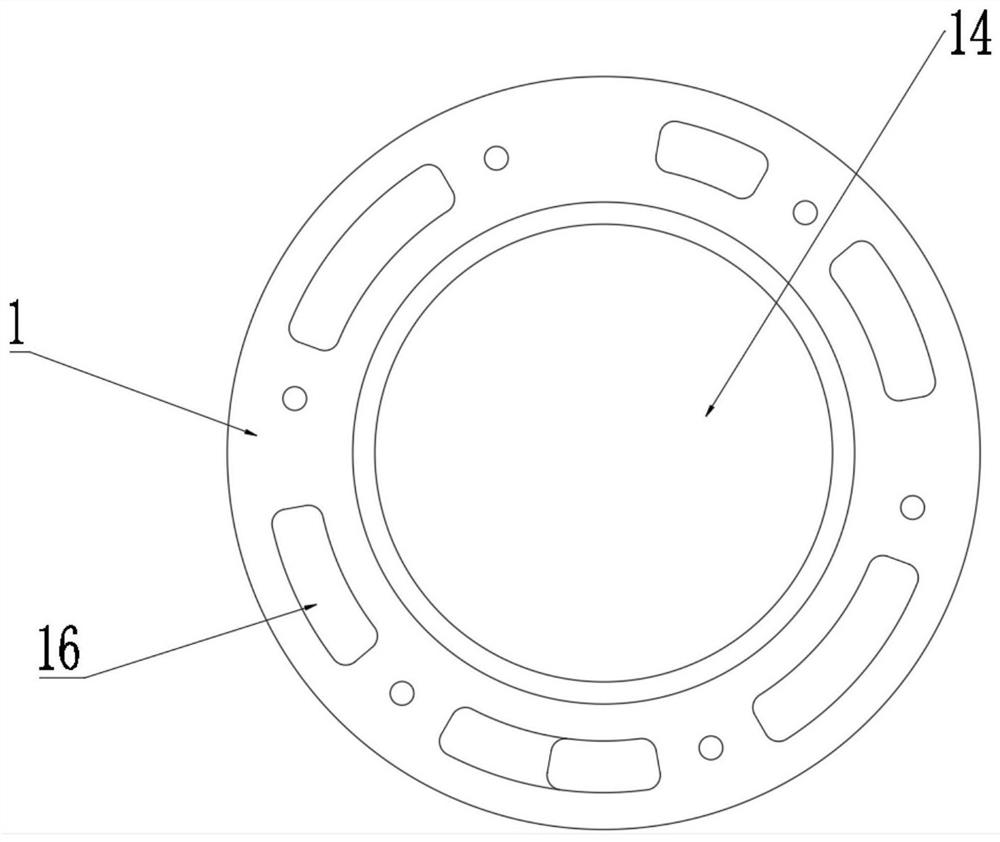

[0042] Such as Figures 1 to 8 as well as Figure 9 As shown, the end cover of the water-cooled bearing box with good sealing effect in this embodiment includes the end cover body 1, and the end cover body 1 is provided with a socket step hole 14, and the diameters from the socket step hole 14 to the butt end to the free end are successively reduced. The socket stepped hole 14 with the smallest diameter matches the size of the drive shaft, and two first sealing rings 11 are embedded on the inner wall of the smallest diameter socket stepped hole 14; the end cover body 1 is far away from the end of the bearing box Also embedded with a second sealing ring 12, the second sealing ring 12 is detachably pressed on the end cover body 1 through a compression cover 17, and the compression cover 17 is detachably fixed on the end cover body 1 by several bolts , when working, the two first sealing rings 11 and the second sealing ring 12 are fitted and sleeved on the rotating shaft, which ...

Embodiment 2

[0049] Such as Figures 1 to 8 as well as Figure 10 As shown, the difference between the end cover of the water-cooled bearing box with good sealing effect in this embodiment and the first embodiment is that the push block 251 and the top connection end of the cleaning slide rod 24 are all arranged on an inclined plane, and the inclined surface has a large contact area, which makes the cleaning slide The rod 24 stretches out to be more efficient for cleaning.

[0050] The working principle of the present invention: when in use, fix the end cover body 1 at both ends of the bearing box, that is, the end cover body 1 is sleeved on the shaft, the first sealing ring 11 and the second sealing ring 12 play a sealing role, and the second sealing ring The ring 12 is pressed on the end surface of the end cover body 1 by the pressing cover 17. Since there is more lubricating oil on the side close to the bearing box, the wear of the first sealing ring 11 is relatively small, while the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com