Hot-melting welding cutter with function of enhancing blood vessel sealing

A technology of hot-melt welding and blood vessels, which is applied in heating surgical instruments, medical science, surgical forceps, etc., can solve the problems of uneven force and thickness of clamping tissue, loose blood vessel sealing, effect influence, etc., and achieves circuit and mechanical design. Simple and reliable, anti-adhesion of the cutter head, and the effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] In order to specifically understand the technical solution provided by the present invention, the technical solution of the present invention will be described and explained in detail in the following embodiments. It is evident that the provided embodiments of the invention are not limited to specific details familiar to those skilled in the art. The preferred embodiments of the present invention are described in detail as follows. Apart from these descriptions, the present invention may also have other embodiments.

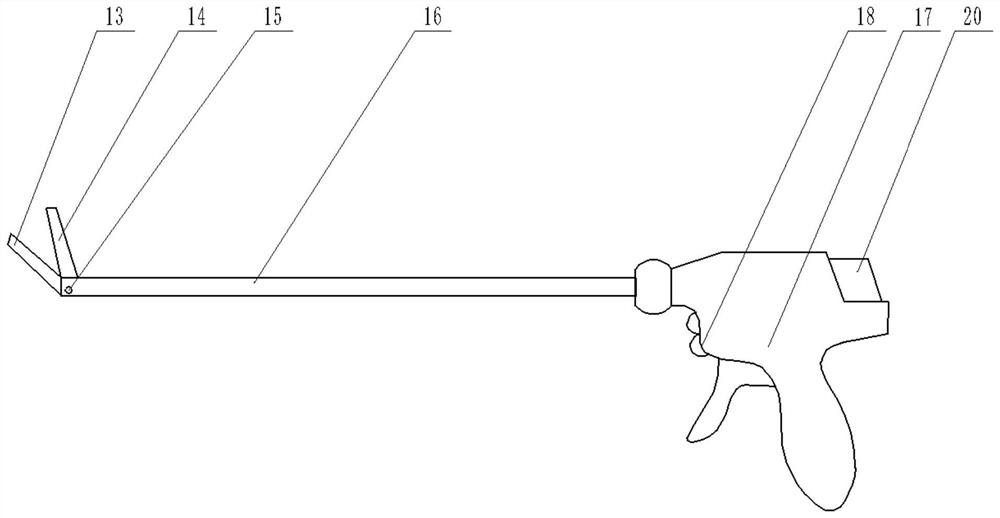

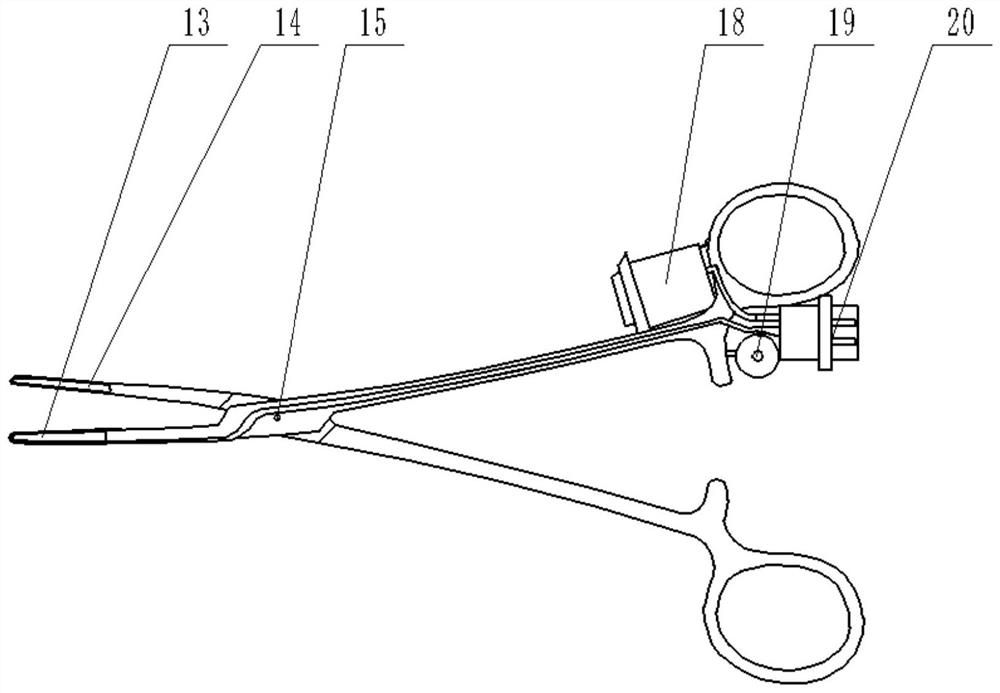

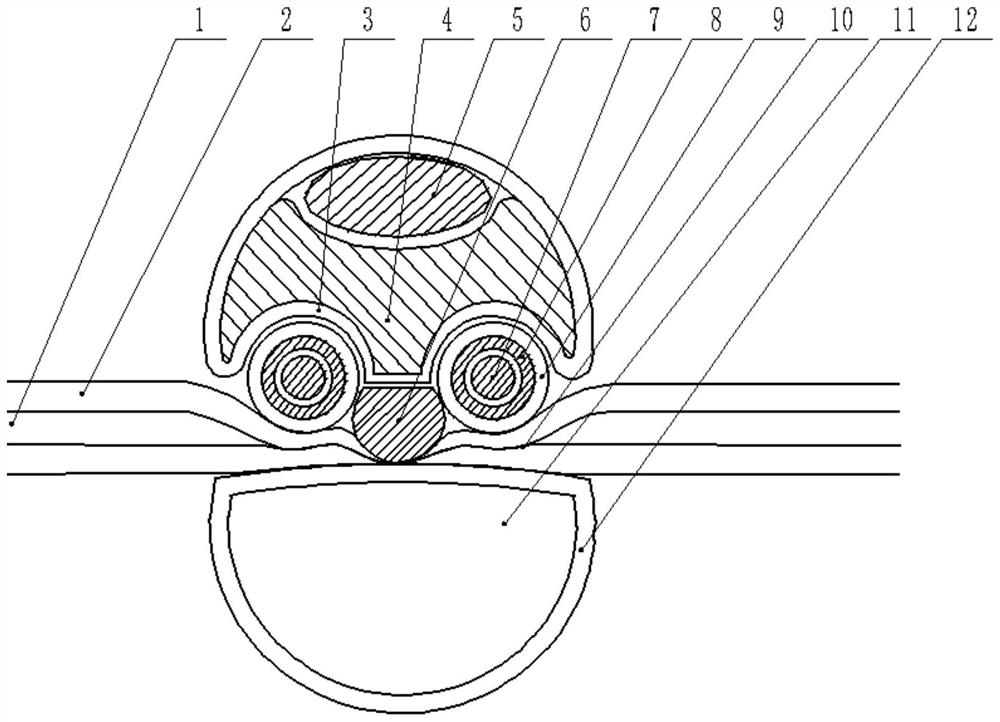

[0021] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the specific embodiment of the present invention relates to a heat fusion welding knife with enhanced blood vessel sealing function, which includes a first working end 13 of the clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com