Boarding ladder hydraulic system, control method and engineering vehicle

A hydraulic system and boarding ladder technology, which is applied in the direction of vehicle components, pedal or ladder arrangement, fluid pressure actuating device, etc., can solve the problems that the boarding ladder cannot be lowered automatically, and the boarding ladder cannot be lowered, so as to reduce the The demand for output capacity, the effect of ensuring smooth flow and ensuring the safety of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

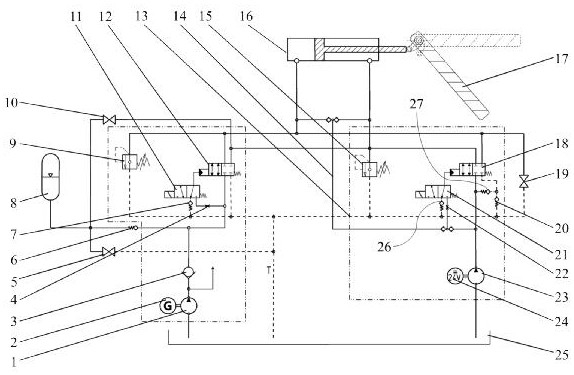

[0031] like figure 1 As shown, a hydraulic system for the boarding ladder, the lifting cylinder 16 is connected to the boarding ladder 17, and the lifting cylinder 16 controls the lifting and lowering of the boarding ladder 17.

[0032] The pilot pump 1 is connected with a power unit 2, and the power unit 2 is an engine or an electric motor. A one-way valve I3 is installed on the oil outlet pipeline of the pilot pump 1, and the oil outlet of the one-way valve I3 is respectively connected with a solenoid valve I11 and a hydraulic control reversing valve I12. The first oil outlet of the hydraulic control reversing valve I12 is connected to the large cavity of the lifting cylinder 16, and the second oil outlet of the hydraulic control reversing valve I12 is connected to the small cavity of the lifting cylinder 16. Orifice I4 is installed on the pipeline between the oil inlet of solenoid valve I11 and the oil outlet of check valve I3, the oil return port of solenoid valve I11 is ...

Embodiment 2

[0036] A boarding ladder control method, using the boarding ladder hydraulic system described in Embodiment 1;

[0037] Lift the boarding ladder at 17:00;

[0038] When the solenoid valve I11 receives the command to lift the boarding ladder, the spool of the solenoid valve I11 works in the left position, and the pilot oil discharged from the pilot pump 1 flows into the hydraulic control reversing valve through the check valve I3, the throttle port I4, and the solenoid valve I11. The control end of I12 is used to adjust the position of the spool and the size of the valve port of the hydraulic control reversing valve I12 to control the operating speed of the lifting cylinder 16;

[0039] The pilot oil flows into the large chamber of the lift cylinder 16 through the one-way valve I3 and the hydraulic control reversing valve I12, the lifting cylinder 16 extends out, and the oil in the small cavity of the lifting cylinder 16 flows back to the oil tank 25 through the hydraulic contr...

Embodiment 3

[0052] An engineering vehicle adopts the hydraulic system of the boarding ladder described in the first embodiment.

[0053] The invention discloses a boarding ladder hydraulic system, a control method and an engineering vehicle, including a boarding ladder lifting system, a lowering system and an emergency lowering system. The lifting system is mainly composed of a pilot pump, a one-way valve, a solenoid valve, a hydraulic control reversing valve, and a safety overflow valve to complete the lifting and state locking functions of the waiting car ladder; the lowering system is composed of an electronic pump, Composed of a solenoid valve, a hydraulic control reversing valve, a safety overflow valve, and a back pressure valve, it completes the normal lowering of the boarding ladder when the engineering vehicle is electrified, and the automatic and stable lowering of the boarding ladder when the engineering vehicle is in an emergency stop; the emergency lowering system is mainly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com