Flexible sensor with contact and non-contact sensing functions and manufacturing method

A flexible sensor and sensing function technology, applied in the field of sensors, can solve the problems of small coupling and difficult balance of detection sensitivity, and achieve the effects of reducing interference, compact structure, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

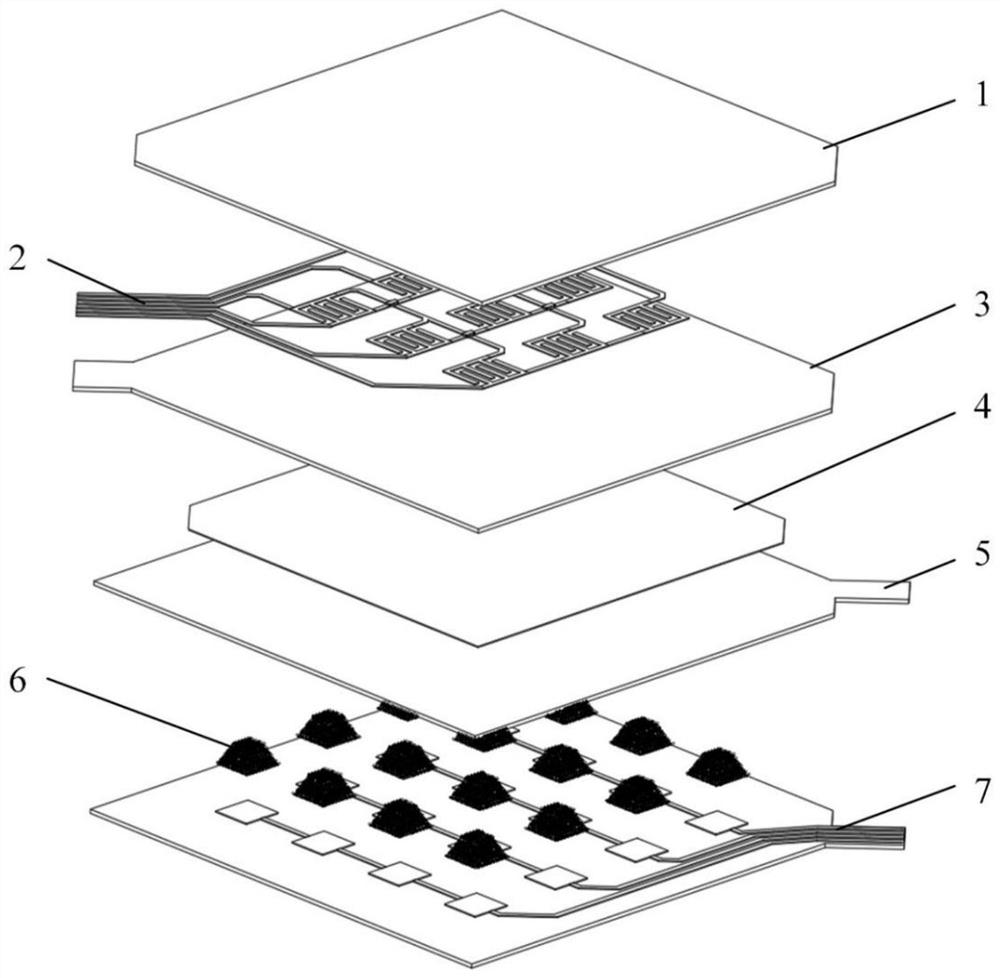

[0077] Such as figure 1 As shown, the flexible sensor includes interdigital electrode packaging layer 1, interdigital electrode layer 2, interdigital electrode base layer 3, capacitive isolation layer 4, piezoresistive top electrode layer 5, porous piezoresistive material layer 6 and piezoresistive bottom electrode layer 7.

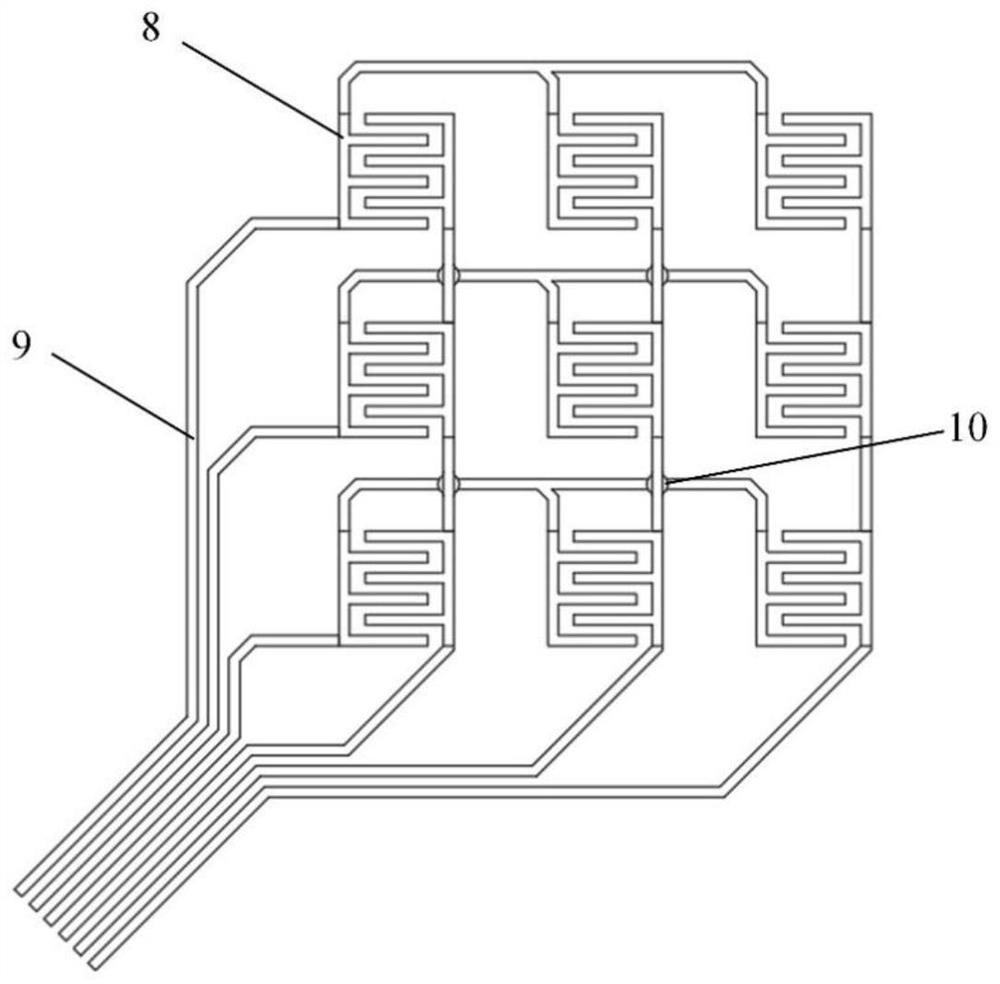

[0078] Such as figure 2 As shown, the interdigital electrode layer 2 includes an interdigital electrode unit 8 and an interdigital electrode layer electrode line 9. A plurality of interdigital electrode units 8 are arranged in an N×N uniformly spaced array, and the number of N interdigital electrode units 8 on the same row One pole forms a set of interdigitated electrode groups in series through electrode wires, and the other poles of N interdigitated electrode units 8 on the same column form a set of interdig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com