Low-frequency broadband composite micro-perforated panel sound absorption structure

A micro-perforated plate, composite technology, applied in the direction of sound-producing instruments, instruments, etc., can solve the problems of narrow sound absorption bandwidth, inability to effectively absorb sound, etc., achieve high peak sound absorption coefficient, simple shape, and improve sound absorption coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

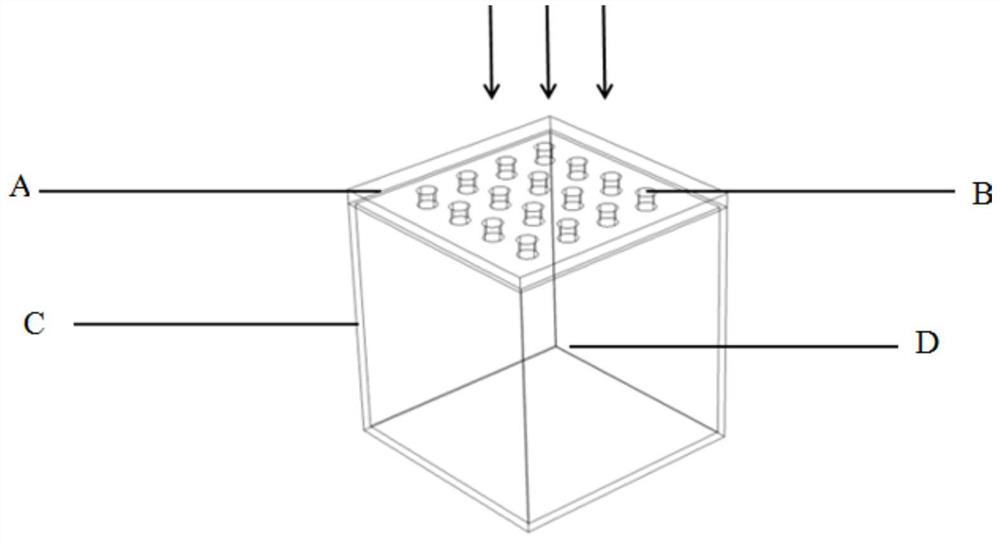

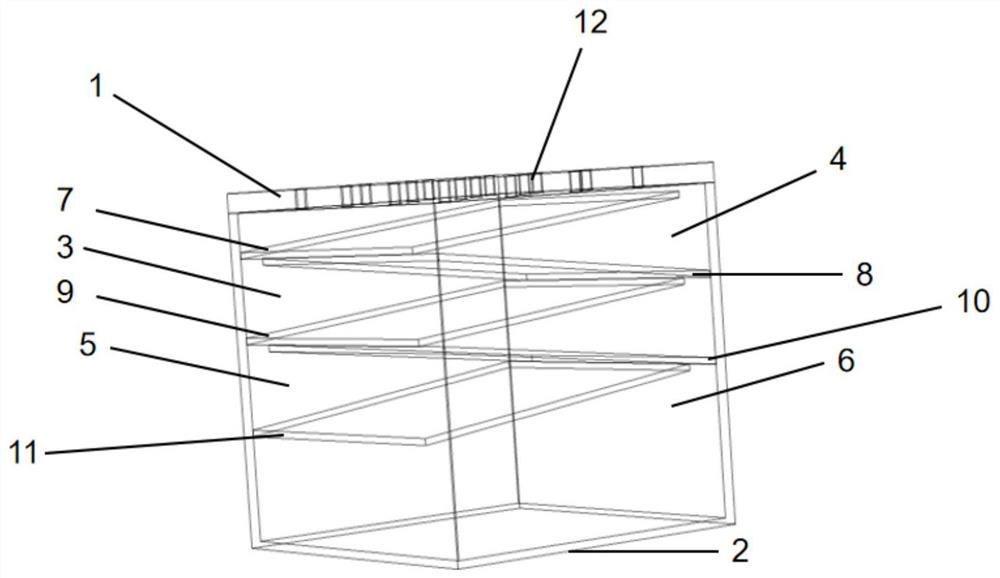

[0039]The size of the perforated plate 1 is 50mm*50mm, and the plate thickness is 0.5mm; the diameter of the submillimeter holes 12 is 0.4mm; 6 mm; the sound-absorbing back cavity is a cube structure with a length, height and depth of 50 mm, and the thickness of all the plates of the sound-absorbing back cavity is 1 mm.

[0040] There are five inclined backboards in the sound-absorbing back cavity, which are inclined backboard I7, inclined backboard II8, inclined backboard III9, inclined backboard IV10 and inclined backboard V11 from top to bottom. The tangent value of the included angle of the horizontal plane is one-tenth, and the distance between the inclined backboard I7 and the perforated plate 1 is 1mm at the near point and 6mm at the far point; the narrow distance between each inclined backboard and the left frame board 3 The width of the slit or the slit between the right side frame plate 4 is 3mm. ; The plate thickness of the inclined back plate is 1mm; all plates ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com