Built-in insulating oil intelligent purification device and method and high-voltage cable oil charging terminal

A purification device and insulating oil technology, applied in the direction of cable terminals, chemical instruments and methods, separation methods, etc., can solve the problems of cable terminal explosion, waste, and endangering the safe operation of high-voltage cables, and achieve the effect of ensuring safe operation and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

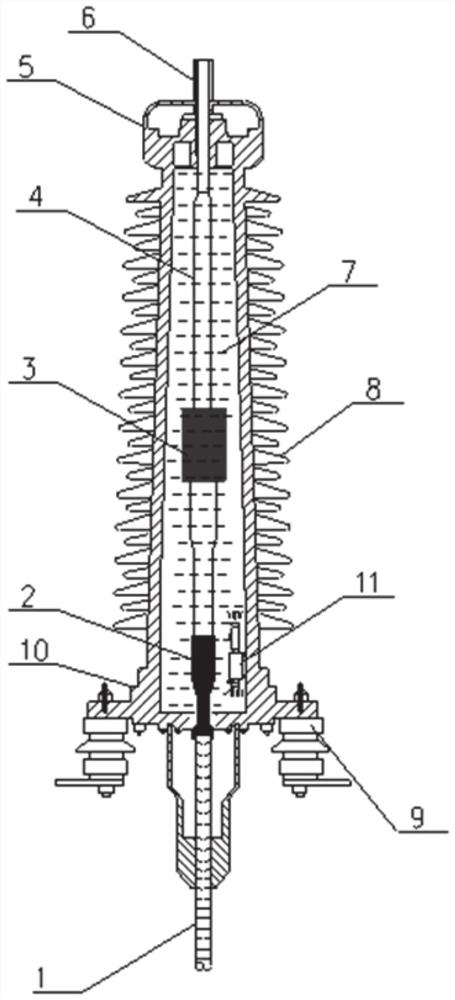

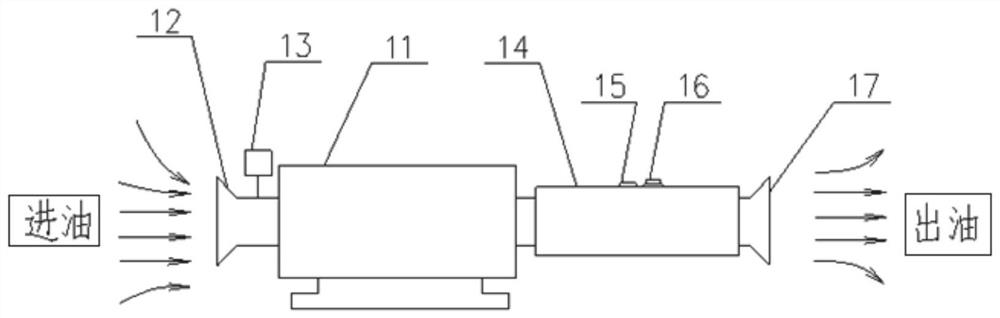

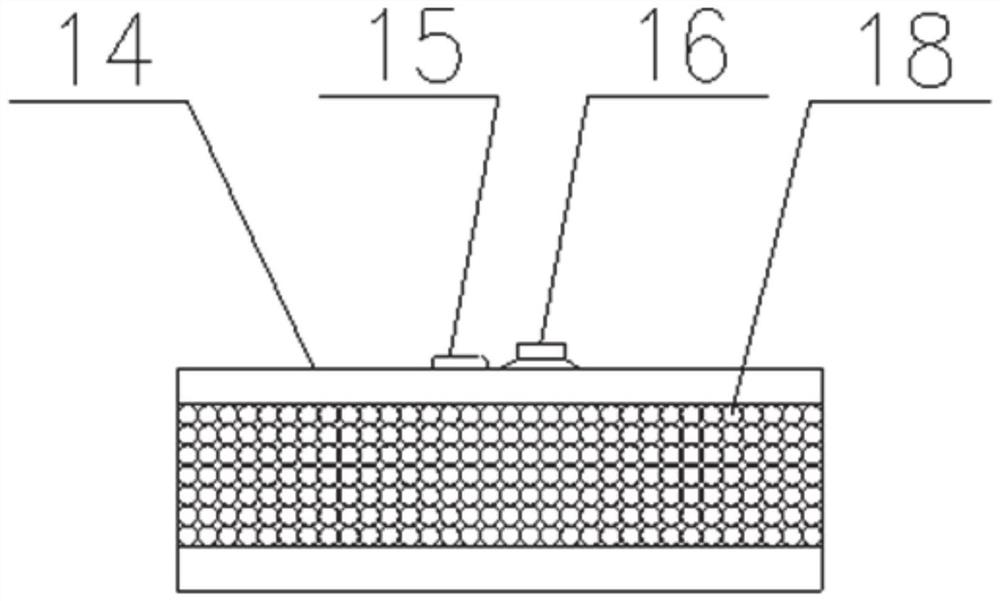

[0029] In the technical solutions disclosed in one or more embodiments, such as Figure 1-5 As shown, the high-voltage cable oil-filled terminal is a built-in intelligent purification device for insulating oil, which can be installed in the high-voltage cable oil-filled terminal to purify the internal insulating oil, including: a built-in part and an external part, and the built-in part is set in the equipment to be purified In the insulating oil, the external part is set outside the equipment to be purified, the external part includes the control device, and the built-in part includes the micro power pump 11, the sensor device and the filter tube, one end of the micro power pump 11 is connected to the filter tube 14, and the micro power pump 11. The sensing devices are respectively connected to two-way radio frequency cards, and wirelessly connected to the control device through the two-way radio frequency cards.

[0030] Further, the external part also includes an air charge...

Embodiment 3

[0054] Based on Embodiment 1, this embodiment provides a control method with a built-in insulating oil intelligent purification device, as follows:

[0055] (1) Set the operating time and interval period of the device in the purification device, and control the operation according to the setting;

[0056] The control device automatically controls the start and stop of the micro power pump 11, the combined sensor 13, and the wavelength sensor 16 according to the set running time and interval period.

[0057] As under normal circumstances, the micro power pump 11 is turned on once a day, and the 1hr program is run at a time to control the operation; the combined sensor 13 is turned on once a day in normal conditions and detected once a day, and the wavelength sensor 16 is turned on and detected once a day.

[0058] (2) Set the required range of detection data, and increase the number of detection times or / and increase the running time or times of the micro power pump 11 when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com