Feeding device for electric coating production

A feeding device and coating technology, applied in solid separation, chemical instruments and methods, grain processing, etc., can solve problems such as accumulation, troublesome cleaning work, and inability to break large particles of materials, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

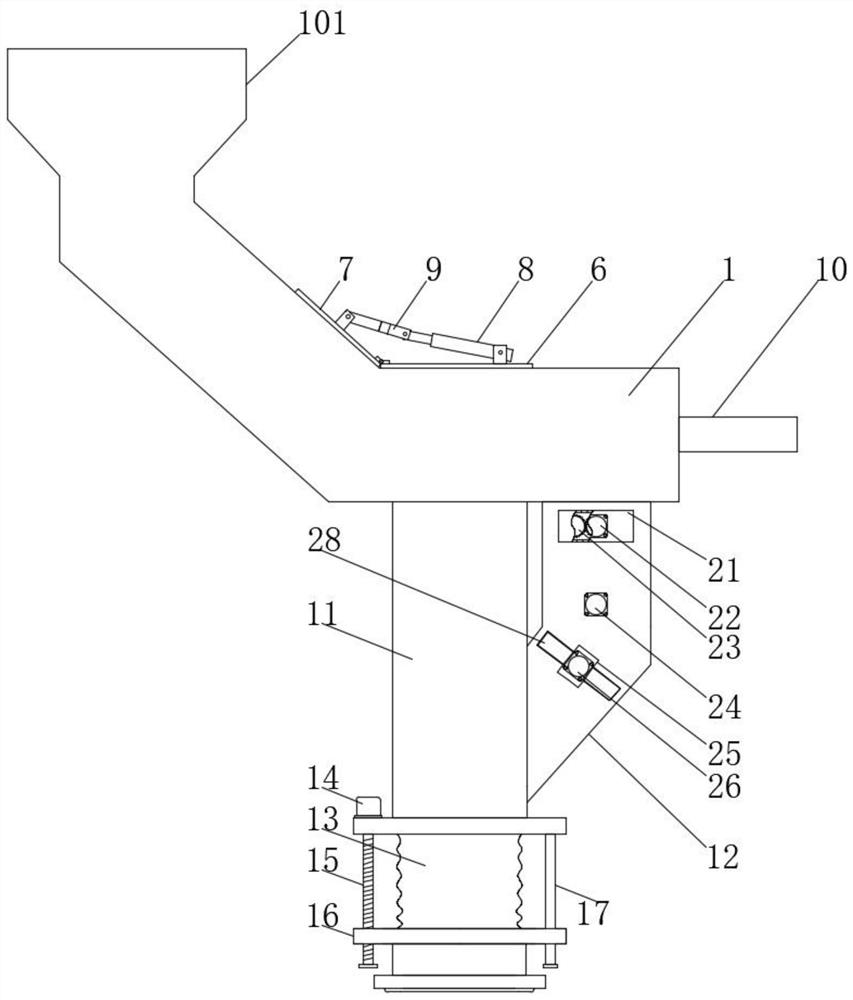

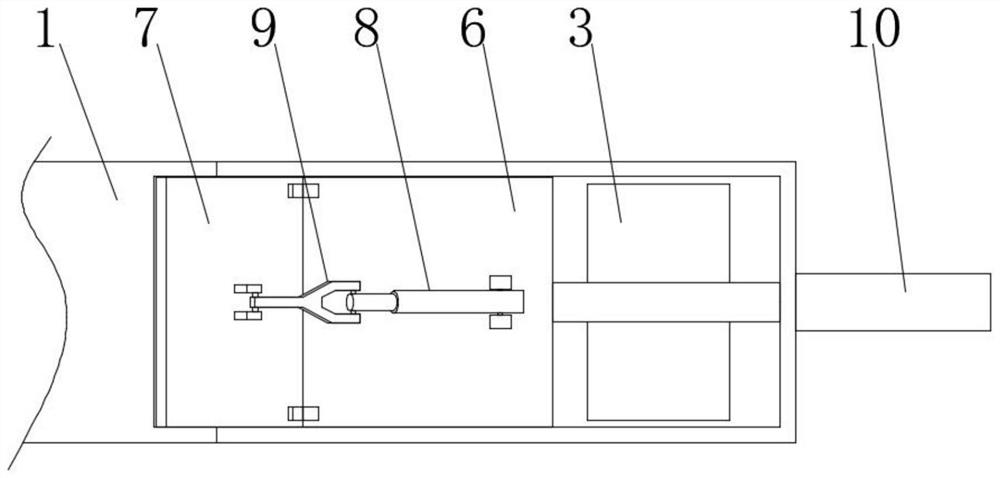

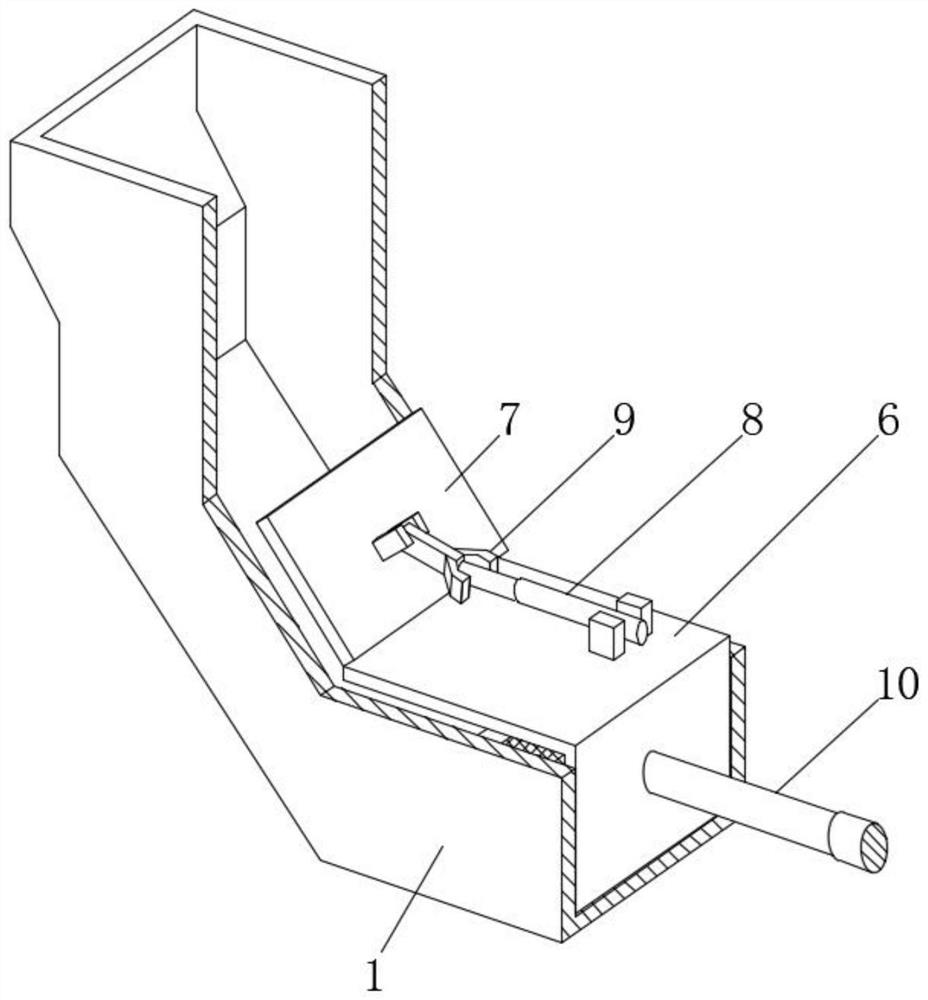

[0028] As shown in the drawings, the embodiment of the present invention provides a feeding device for the production of electric paint, including a feeding channel 1, the top of the feeding channel 1 is provided with a feeding port 101, and the bottom end of the feeding channel 1 is far away from the feeding port One side of 101 is evenly provided with two material guide ports 3, and the inner side of one of the material guide ports 3 is provided with a screen 2, and the edge of the screen 2 is fixedly connected with the inner wall of the material guide port 3 with an elastic leather sheath 5. A vibrating motor 4 is fixedly connected to the bottom of the screen 2, a pushing assembly is arranged on the top side of the screen 2, and a first material guide pipe 11 and a second guide tube 11 are fixedly connected to the bottom ends of the two material guide ports 3 respectively. The feed pipe 12, and the second feed pipe 12 and the first feed pipe 11 are connected to each other, t...

Embodiment 2

[0036] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0037] Specifically, the bottom end of the first material guide pipe 11 is fixedly connected with a telescopic cover 13, the bottom end of the telescopic cover 13 is fixedly connected with a butt joint 16, and the bottom side of the first material guide tube 11 is fixedly connected with a drive motor 14, and the drive motor The output end of 14 is fixedly connected with an adjusting screw 15, which is threadedly connected with the butt joint 16, so that the adjustment screw 15 drives the butt joint 16 to move down through the drive of the drive motor 14 until the butt joint 16 and the production equipment enter The material end is butted, so as to prevent the material from splashing out from between the first material guide pipe 11 and the feeding end of the production equipment when it falls into the production equipment.

[0038] Specifically, the side of the butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com