Method for preventing mixed crystals from being generated at free end of conjoined single crystal guide blade core

A technology of guide vane and free end, which is applied in the field of preventing miscellaneous crystals at the free end of the conjoined single crystal guide vane core, can solve the problems of edge plate miscellaneous crystals, etc., and achieve the effect of easy trimming, simple trimming operation, and easy drying of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

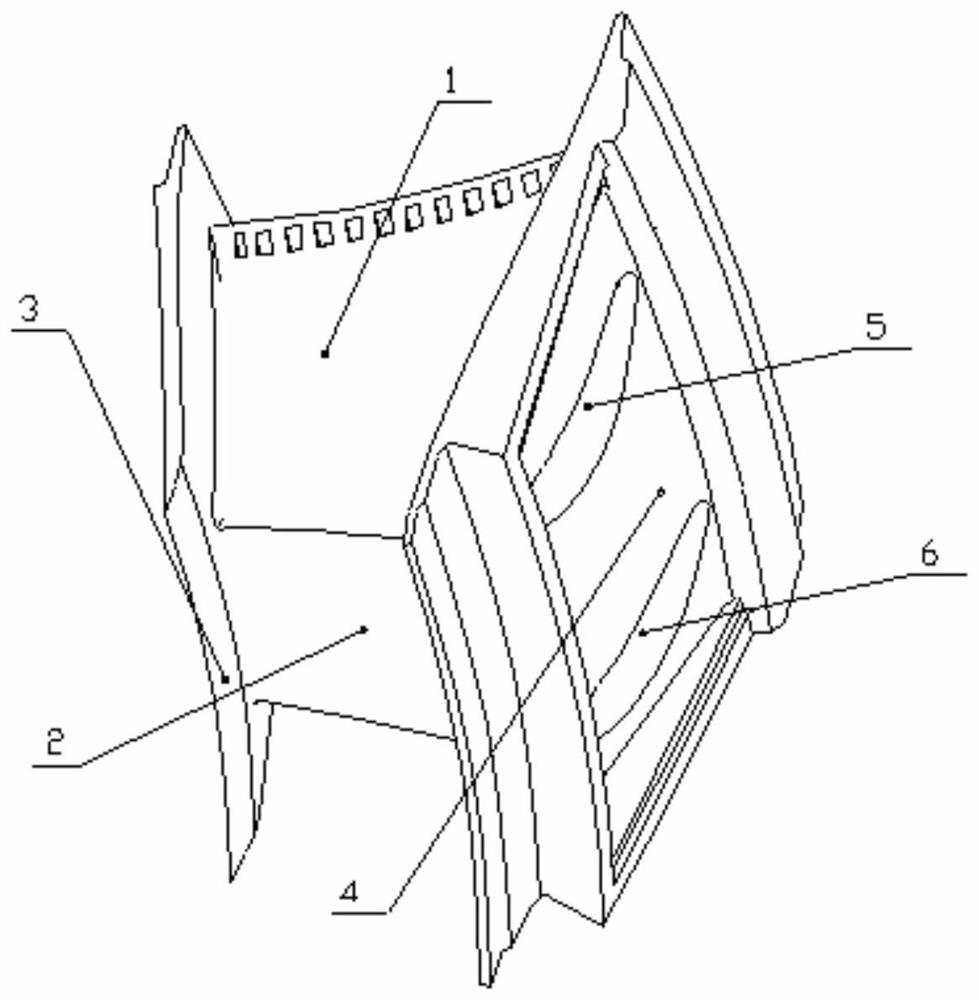

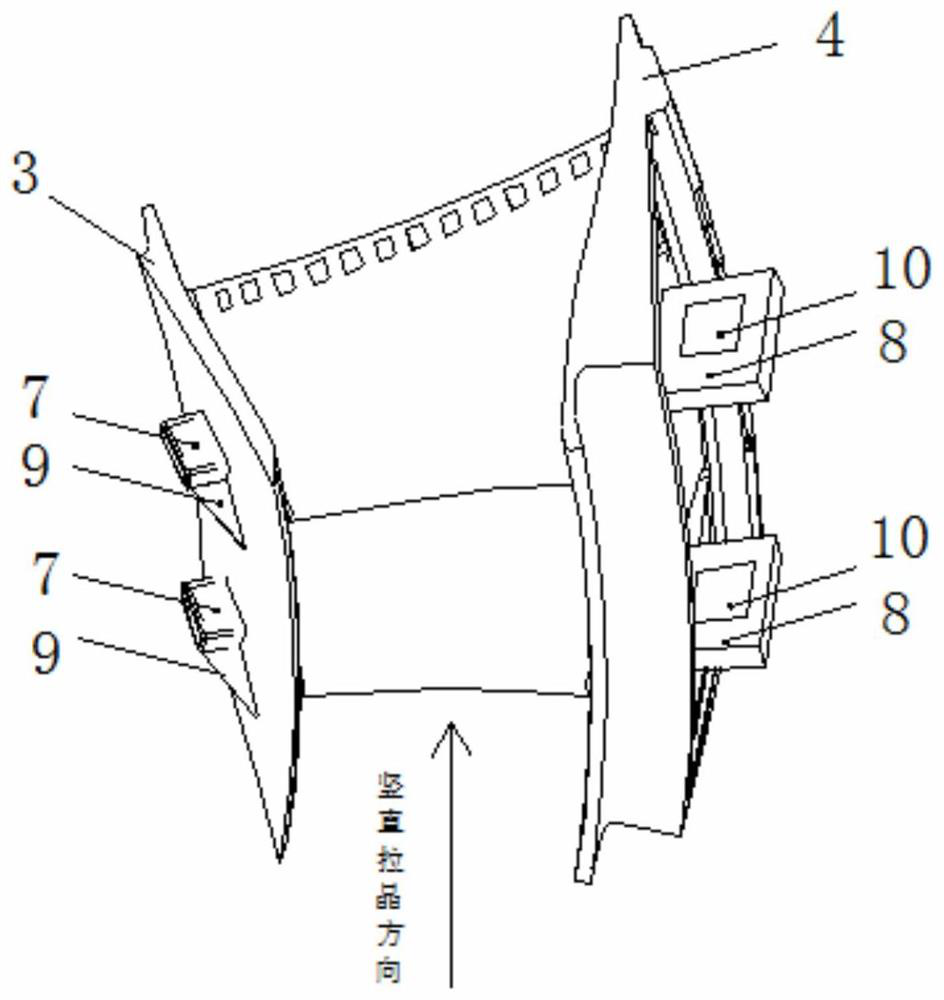

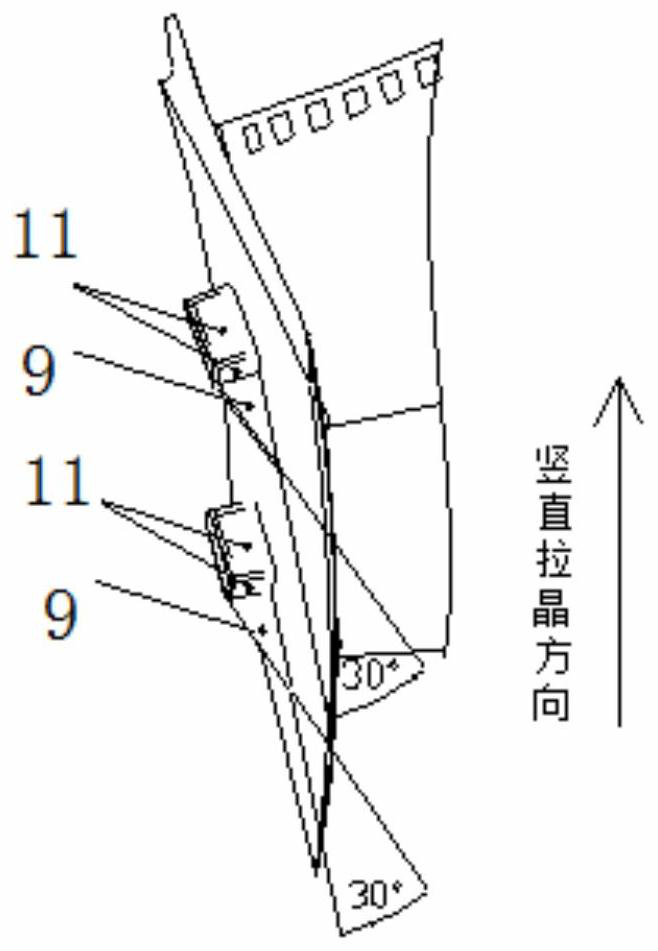

[0015] Such as Figure 1-3 As shown, a method for preventing stray crystals at the free end of the conjoined single-crystal guide vane core comprises the following steps:

[0016] Step 1. Both the free end 7 and the fixed end 8 of the core are of cuboid structure, the side of the small edge plate 3 of the blade is the free end 7 of the core, the side of the large edge plate 4 of the blade is the fixed end 8 of the core, and the fixed end 8 of the core is Groove 10 is provided; the size of the rectangular cross-section of the fixed end 8 of the core is set according to the cross-section size of the outlet of the first inner cavity 5 of the blade body and the second inner cavity 6 of the blade body, and is fixed by the core It is advisable that the rectangular cross-section of the end 8 is inscribed in the cross-section of the inner cavity outlet on one side of the large edge plate 4 of the blade. The fixed end 8 of the core protrudes from the blade body and the length is 30-40m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap