Patents

Literature

50results about How to "Easy trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

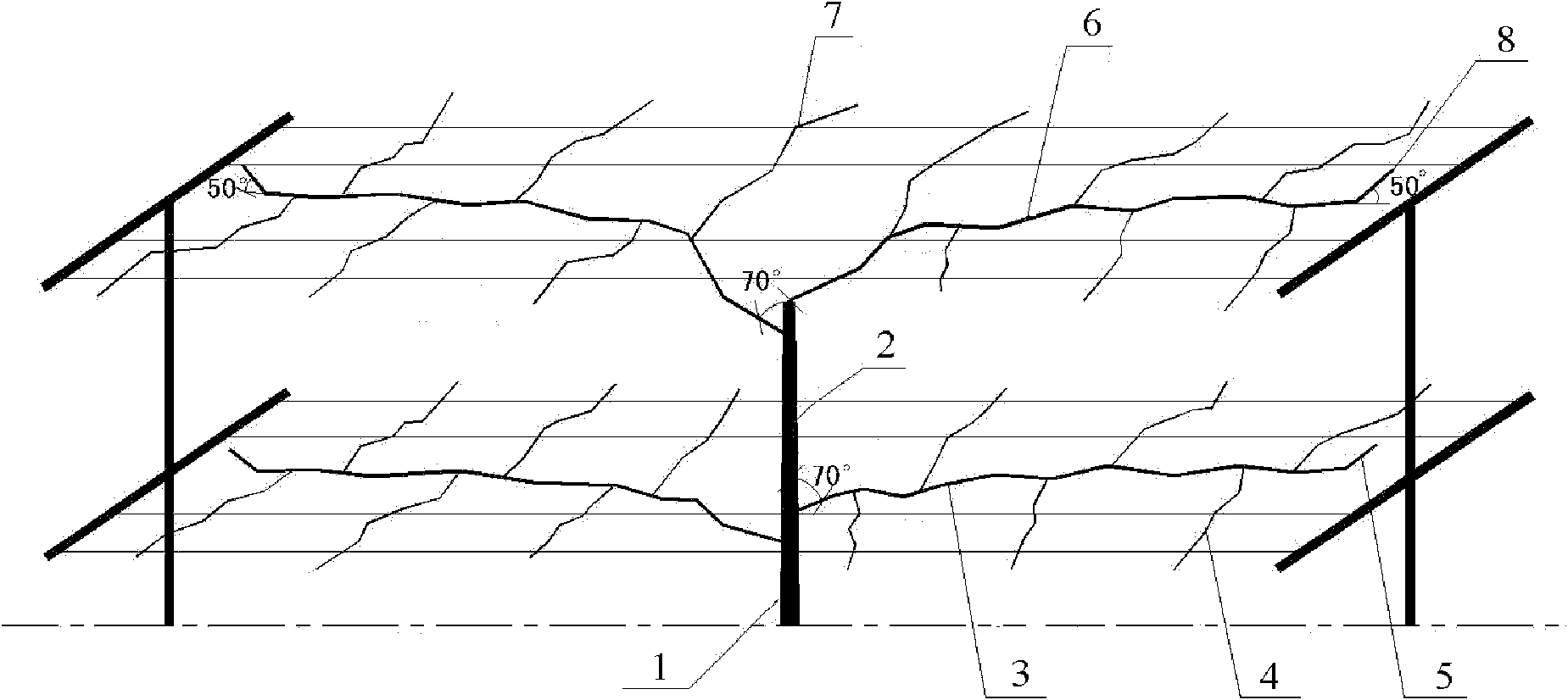

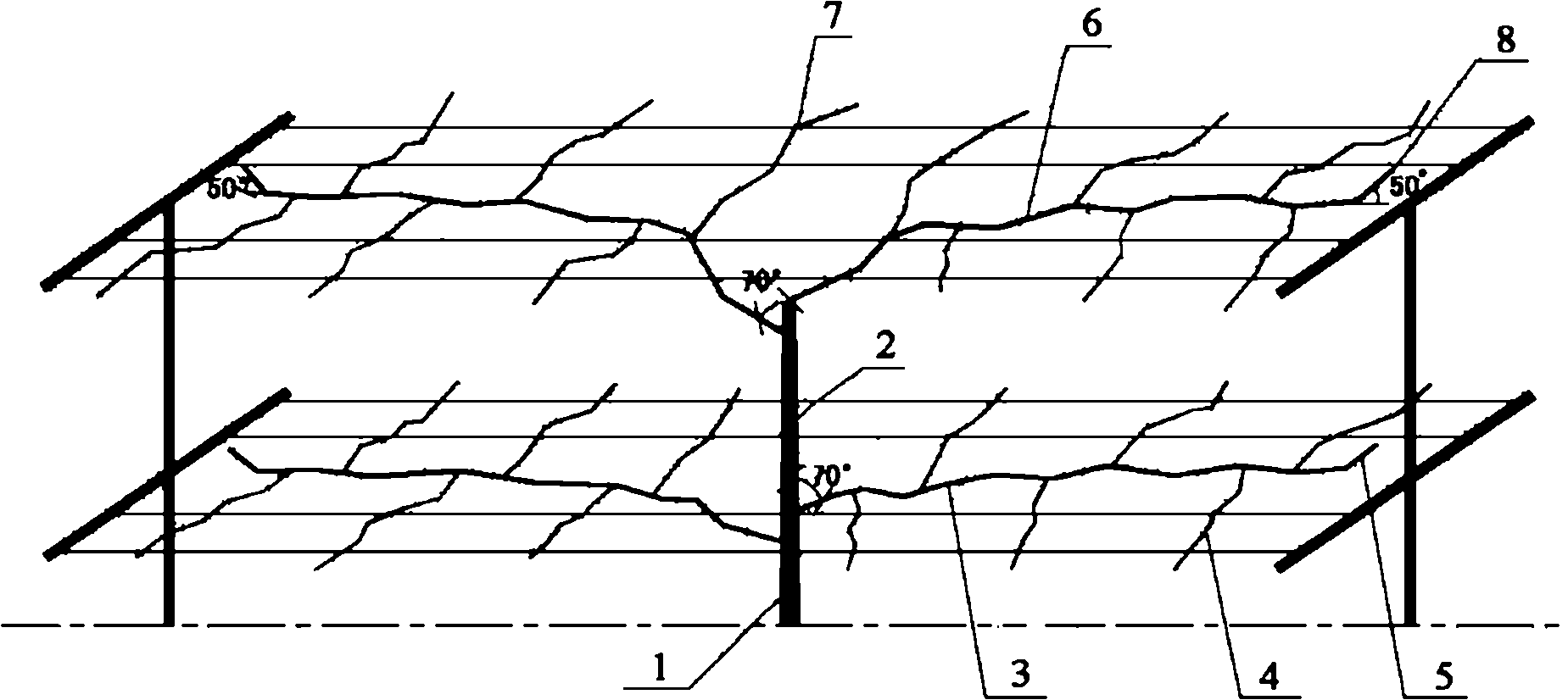

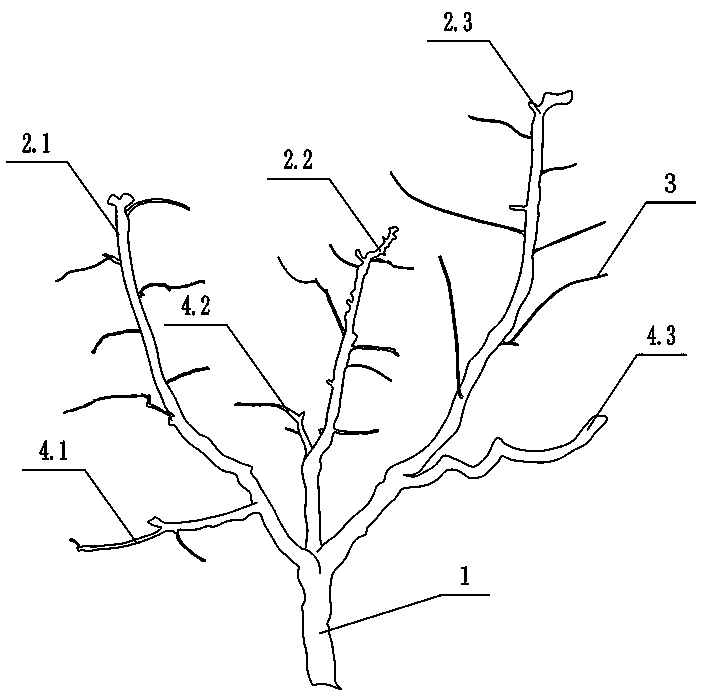

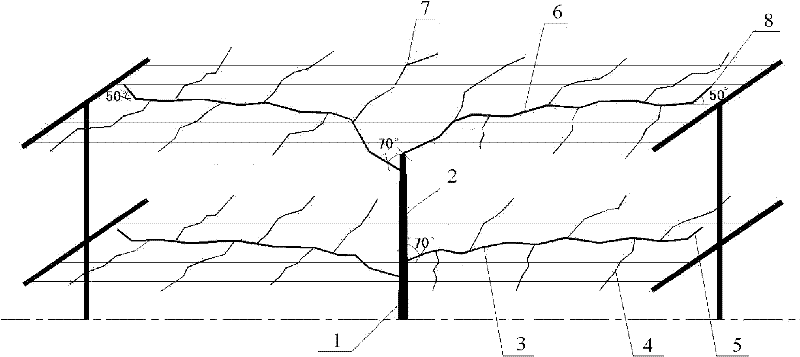

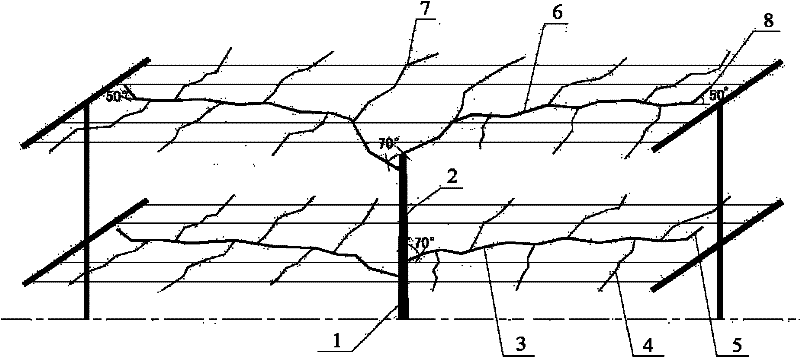

Shaping and trimming method of crowns of pear trees

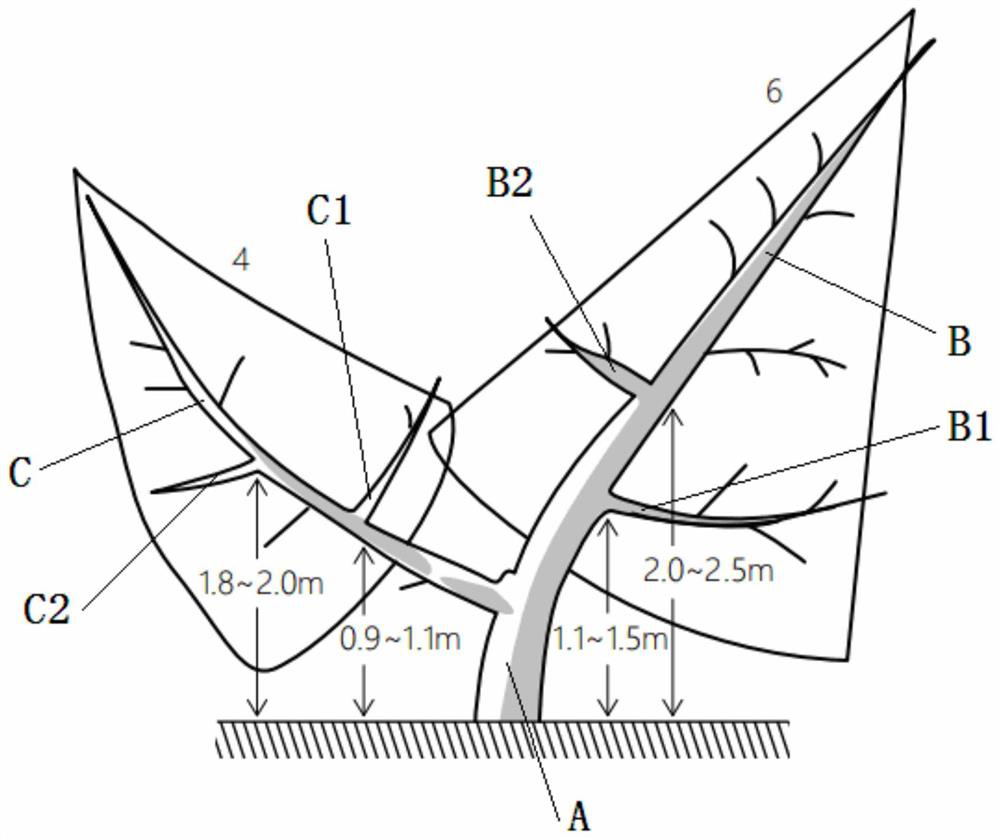

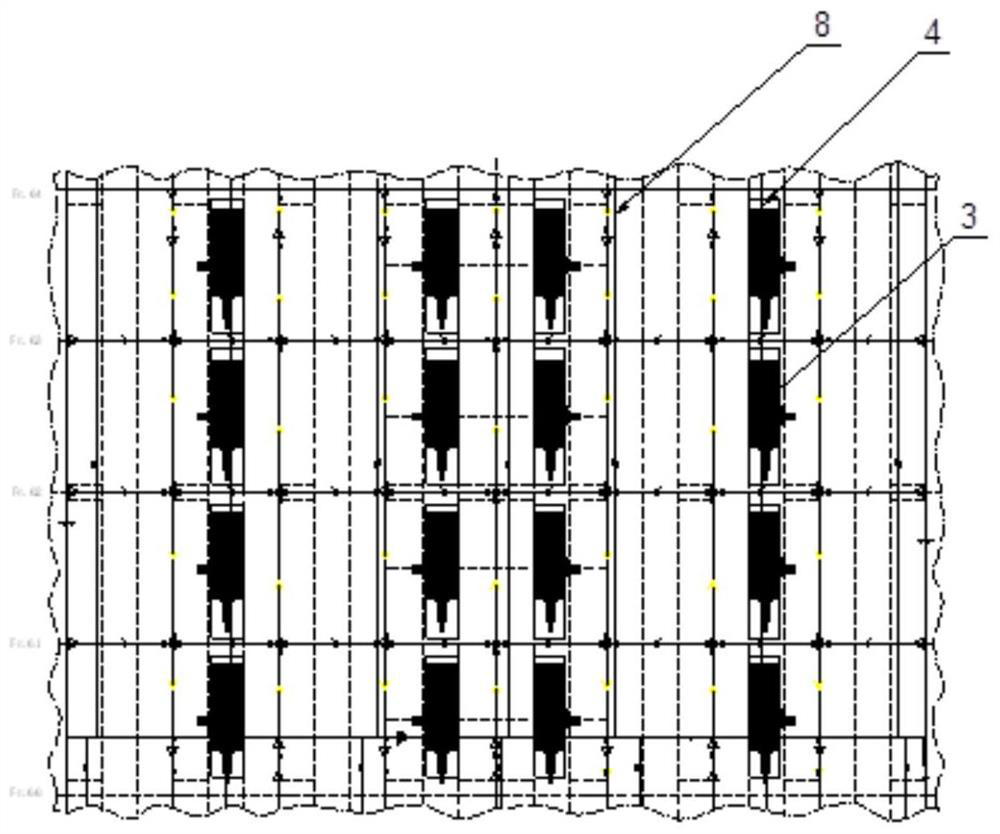

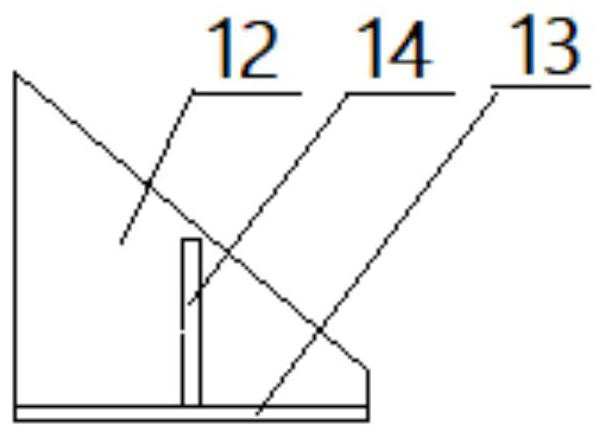

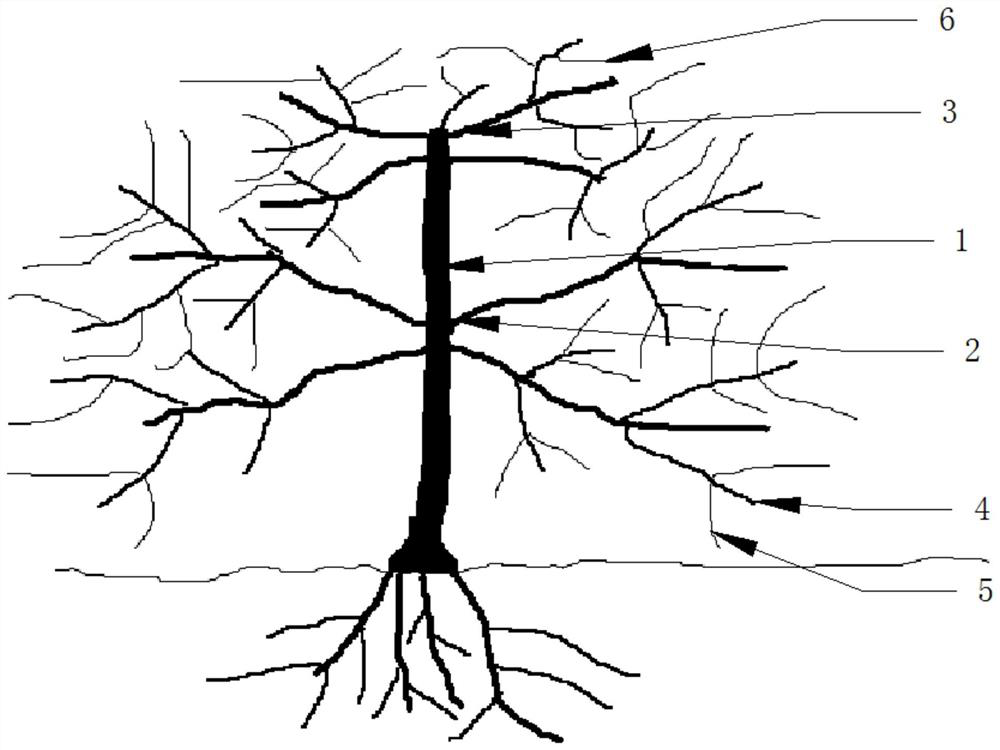

The invention relates to a shaping and trimming method of crowns of pear trees. The crowns are trimmed into a structure of two layers of main branches, wherein each layer of main branches comprises two main branches facing south and north, and lateral branches are left at two sides of the main branches in the horizontal direction. The shaping and trimming method has the advantages of facilitating flower bud differentiation, increasing effective photosynthetic accumulation, enhancing wind resistance, and obviously improving the commodity quality of fruit of a single-layer planar pergola shaping method; moreover, the shaping of the crowns is quick; the cultivation of crown structure can be completed to enter the early fruit period 3 years after the planting in general; the yield of a single plant can be controlled to be 6-10kg, and increases year by year; meanwhile, trimmed crowns do not contain sub-main branches; the trimming method is simple, and is easy to master; the work space of the flower and fruit management of a pear orchard can be controlled; labor and force are saved; the labor efficiency is improved; and the management cost of the orchard is reduced; in addition, the method is suitable for a flat land or a gentle slope landform undulation, and is particularly suitable for a gentle slope with the landform undulation or a slope land with the slope of less than 15 DEG.

Owner:YANGZHOU UNIV +1

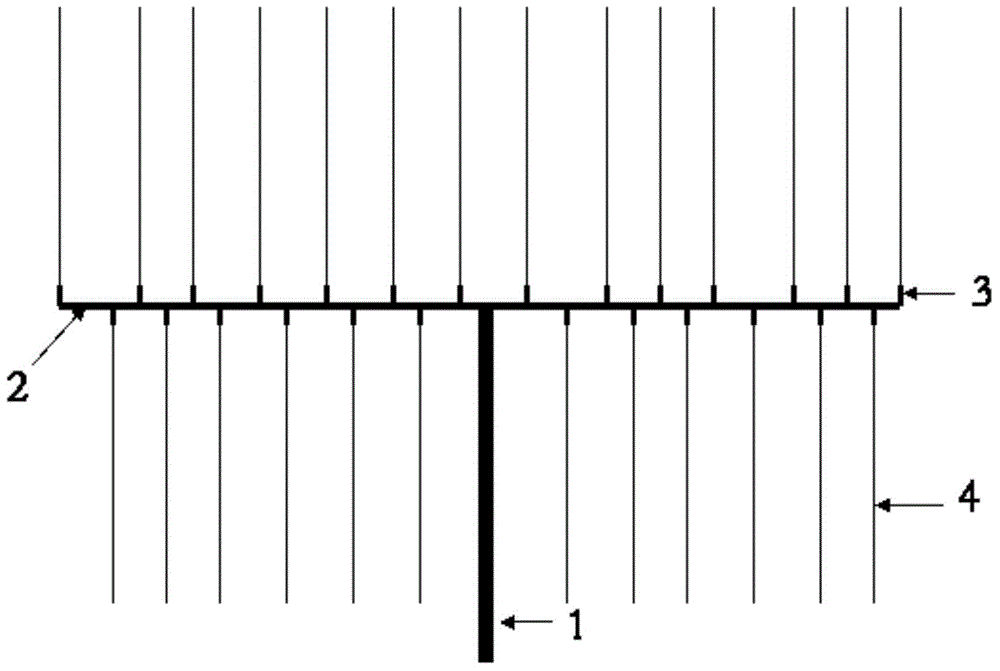

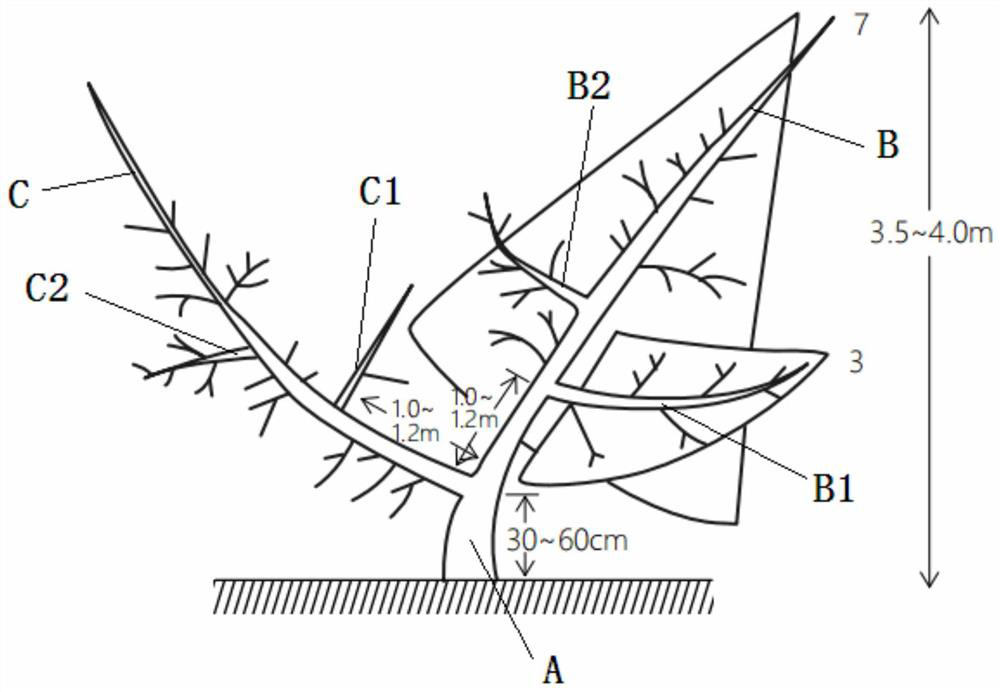

High slender spindle-shaped apple tree form and trimming method thereof

InactiveCN101755655ACrown small and tallStrong result abilityCultivating equipmentsDecapitationUltimate tensile strength

The invention discloses a high slender spindle-shaped apple tree form and a trimming method thereof. As a whole, the tree form is of high slender spindle shape. After an apple tree is formed, the crown diameter of the apple tree is small, slender and high. The apple tree is 3.5-4.0m high and the trunk of the apple tree is 0.8-0.9m high. Thirty to fifty spirally arranged small boughs are grown on the central leading trunk of the apple tree. The average length of the small boughs is 1m. The average angle between the central trunk and the small bough is 115 degrees. The top-to-bottom spacing among the small boughs on the same side is 0.25m. The trimming method of the high slender spindle-shaped tree form is simple. Other boughs require no decapitation but branch drawing except that the central trunk requires short-cutting in winters in 1-2 years. Thereby, the trimming method can be popularized in tree forms of simplified trimming and low labor strength.

Owner:NORTHWEST A & F UNIV

Ready-to-eat meat food and manufacturing process thereof

The invention relates to a ready-to-eat meat food and a manufacturing process thereof, which belong to the technical field of ready-to-eat meat foods and manufacturing processes thereof. According to the invention, through taking 1-2 parts of pork, 0.1-0.3 part of pigskin, 1-2 parts of chicken and 0.5-0.7 part of pig fat as main materials and combining with auxiliary materials, a ready-to-eat meat food is prepared, so that the problem that a pork skin containing meat food is poor in flavor and taste in the prior art is solved, and a formula and a proportion for ready-to-eat meat foods are provided, therefore, a situation that a product keeps the flavor and taste of fresh meat products for a long time can be guaranteed. Compared with traditional processes, by using the manufacturing process of the ready-to-eat meat food provided by the invention, the natural flavor of meat can be kept better; and meanwhile, the storage time of products can be improved, and the storage cost can be reduced.

Owner:SICHUAN GAOJIN FOOD CO LTD

Shaping and pruning method for plum trees and apricot trees

ActiveCN111108949AIncrease productionSmall footprintCultivating equipmentsHorticulture methodsFruit treeAlcohol sugars

The invention relates to the technical field of fruit farming, in particular to a shaping and pruning method for plum trees and apricot trees. According to the shaping and pruning method for plum trees and apricot trees, the first year growth period: seedlings are planted in autumn or early spring, and primary main branches are cultivated; the first year dormancy period: secondary main branches are cultivated; the second year growth period: the secondary main branches are established; the second year dormancy period: lateral branches are cultivated; the third year growth period: the lateral branches are established; the third year dormancy period: fruiting branches are cultivated; overdense weak branches of the primary main branches, the secondary main branches and the lateral branches aresparsely separated from the base, leaving a short cut of 2-5 cm when over 1 / 2 of the thickness of a raw branch; in the fourth year of growth, potassium dihydrogen phosphate and sugar alcohol boron are sprayed once in June and July respectively to ensure flower buds differentiation in summer and fruit bearing in the next year; and in the fourth year of dormancy, tree shape is kept, and excessive branches and overdense branches disturbing the tree shape are removed to ensure that the thickness of branches is progressively reduced. The shaping and pruning method can make full use of cubical space, save land resources and prone to managing.

Owner:SICHUAN AAS HORTICULTURE RES INST

Low-shrinkage treatment method and afterfinishing method of high-elastic fabric and high-elastic fabric

ActiveCN106988072ASmall shrinkageSolve curlingShrinkingSucessive textile treatmentsEnvironmental engineeringLow shrinkage

The invention discloses a low-shrinkage treatment method and afterfinishing method of high-elastic fabric and high-elastic fabric; the low-shrinkage treatment method of the high-elastic fabric comprises: washing the high-elastic fabric; dewatering the treated high-elastic fabric; scotching the high-elastic fabric; drying the high-elastic fabric. The low-shrinkage treatment method of the high-elastic fabric provided herein has an additional treatment step in the original fabric afterfinishing method; low-shrinkage treatment is arranged before pre-shrinkage treatment. The high-elastic fabric treated by the low-shrinkage treatment method gains high elasticity and low shrinkage, the difficulty in manufacturing high-elasticity ready-made apparel and washing the ready-made apparel is reduced greatly.

Owner:GUANGDONG FORWARD DENIM

High-yield pruning method for oiltea camellia trees

InactiveCN106258739AEasy trimmingPromote growthCultivating equipmentsHorticulture methodsCamellia oleiferaHead shape

The invention relates to the technical field of oiltea camellia tree planting management, and particularly relates to a high-yield pruning method for oiltea camellia. The method comprises young wood pruning and adult wood pruning, wherein young wood pruning comprises forming a natural open core shape and a natural round head shape; by virtue of adult wood pruning, oiltea camellia trees are good in growth vigour, early in fruiting and high in yield. Tests prove that the yield of the pruned oiltea camellia trees is increased by about 30% in comparison with non-pruned oiltea camellia trees; in addition, the high-yield pruning method for the oiltea camellia trees is simple, simple and convenient in step, low in cost, and easy to popularize and use.

Owner:HUNAN LYUBO AGRI & FORESTRY DEV CO LTD

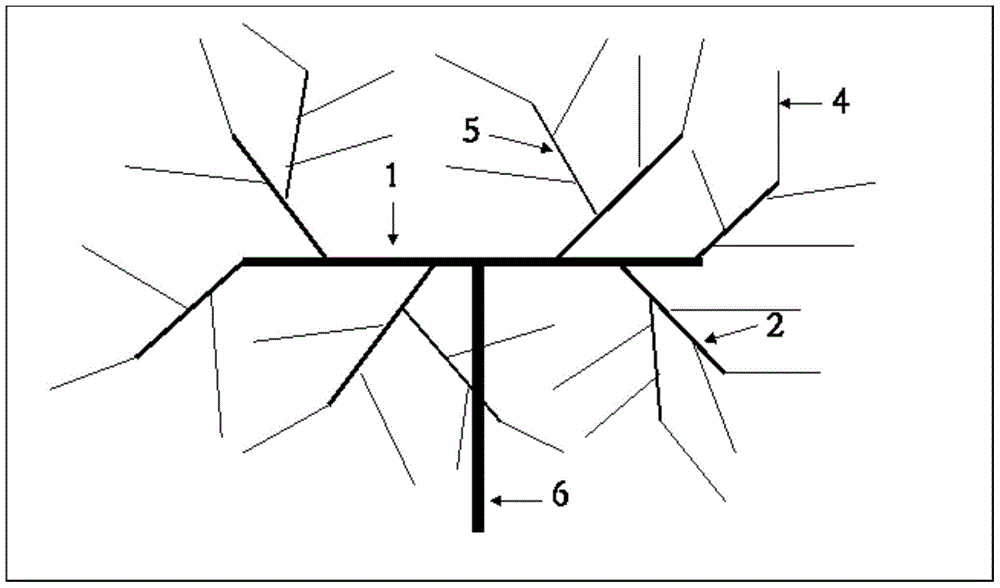

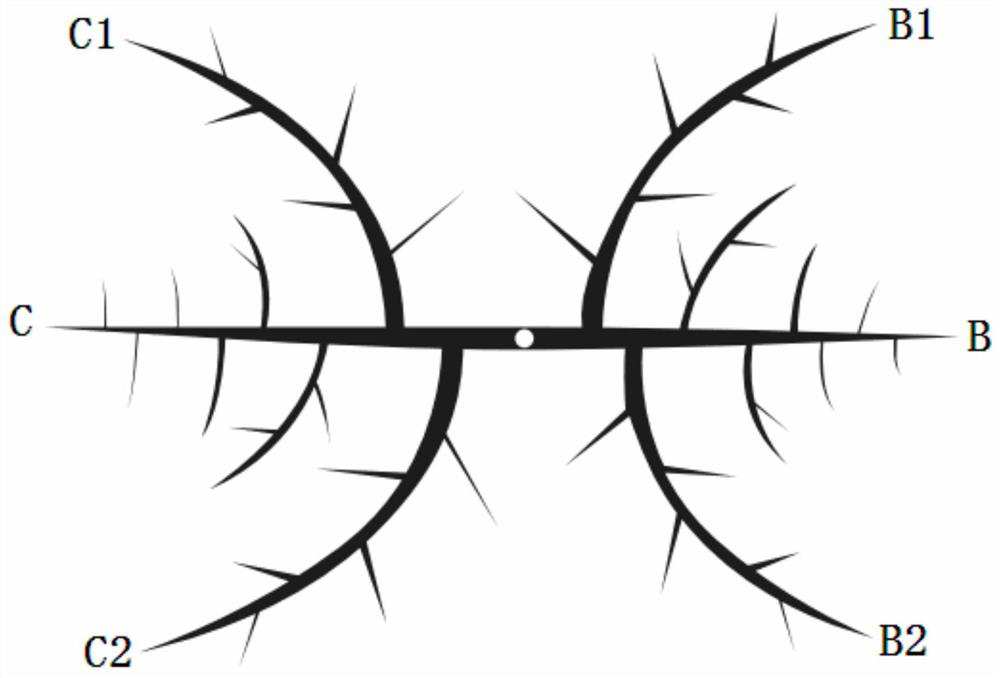

Kiwifruit fishbone-shape simple pruning method

InactiveCN105519395AEasy trimmingImprove labor efficiencyCultivating equipmentsHorticulture methodsMain branchActinidia

The invention discloses a kiwifruit fishbone-shape simple pruning method. Only two main branches are remained on the main trunk of each kiwifruit tree, wherein the two main branches are respectively located on the two sides of the main trunk. After fruiting, fruiting base branches on the main branches are all cut off, wherein piles with lengths of 1-2cm are remained; robust vegetative branches of the current year from the main branches or from the main branch piles are selected as fruiting base branches for the next year, wherein the fruiting base branches are regularly arranged on the two sides of the main branches; the spacing for the fruiting base branches on a same side is 20-25cm, and the fruiting base branches on the two sides are arranged alternately. The method has the following advantages: the pruning method is simple and is easy to learn; labor efficiency is high; the yield is increased by approximately 30%; kiwifruit overall quality is high; the trees are neatly arranged, and are beautiful, such that a garden art sensory is provided.

Owner:XIANNING XINDE MODERN AGRI TECH

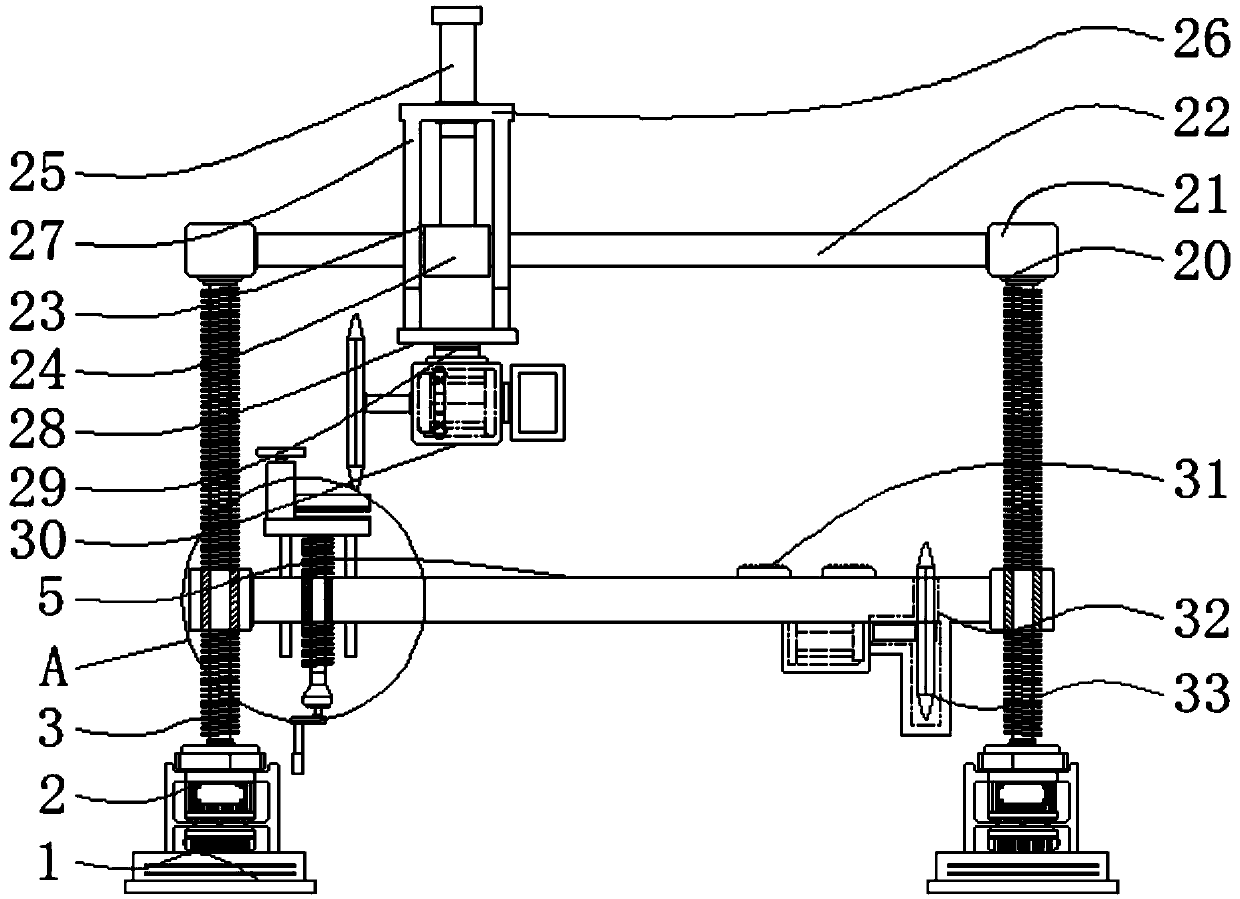

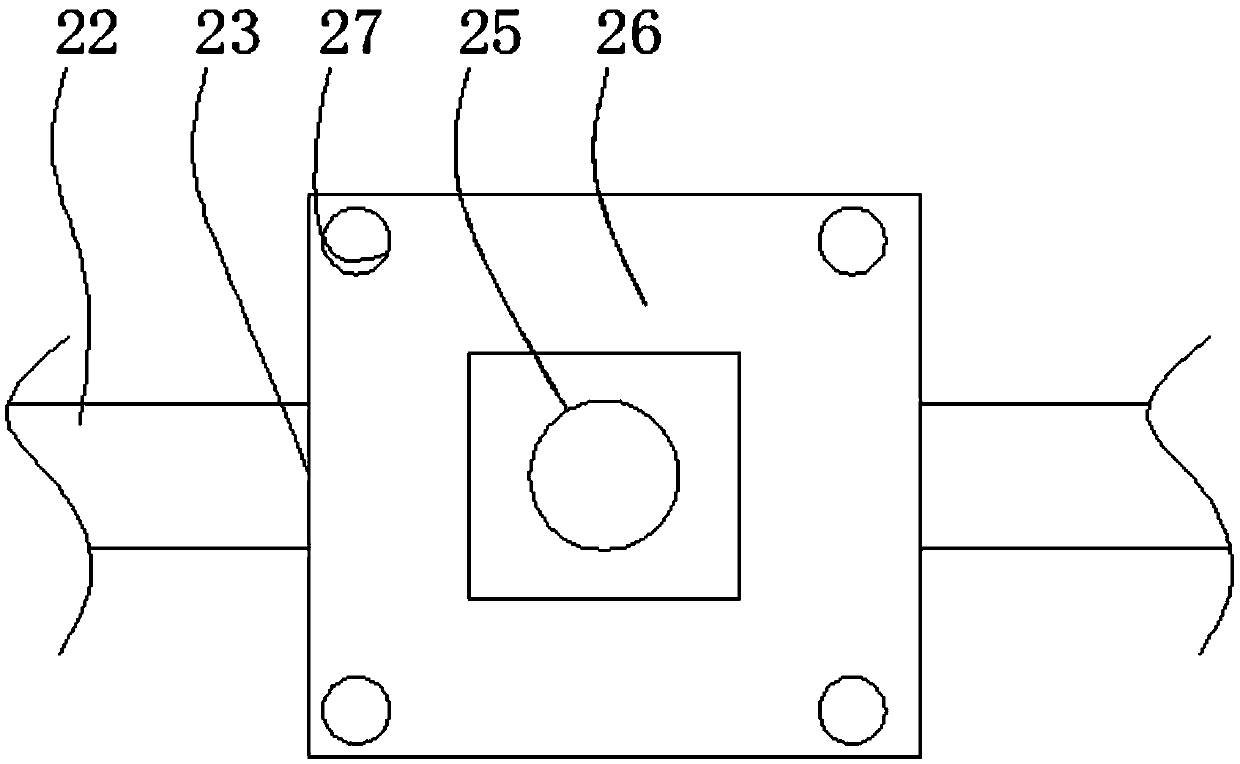

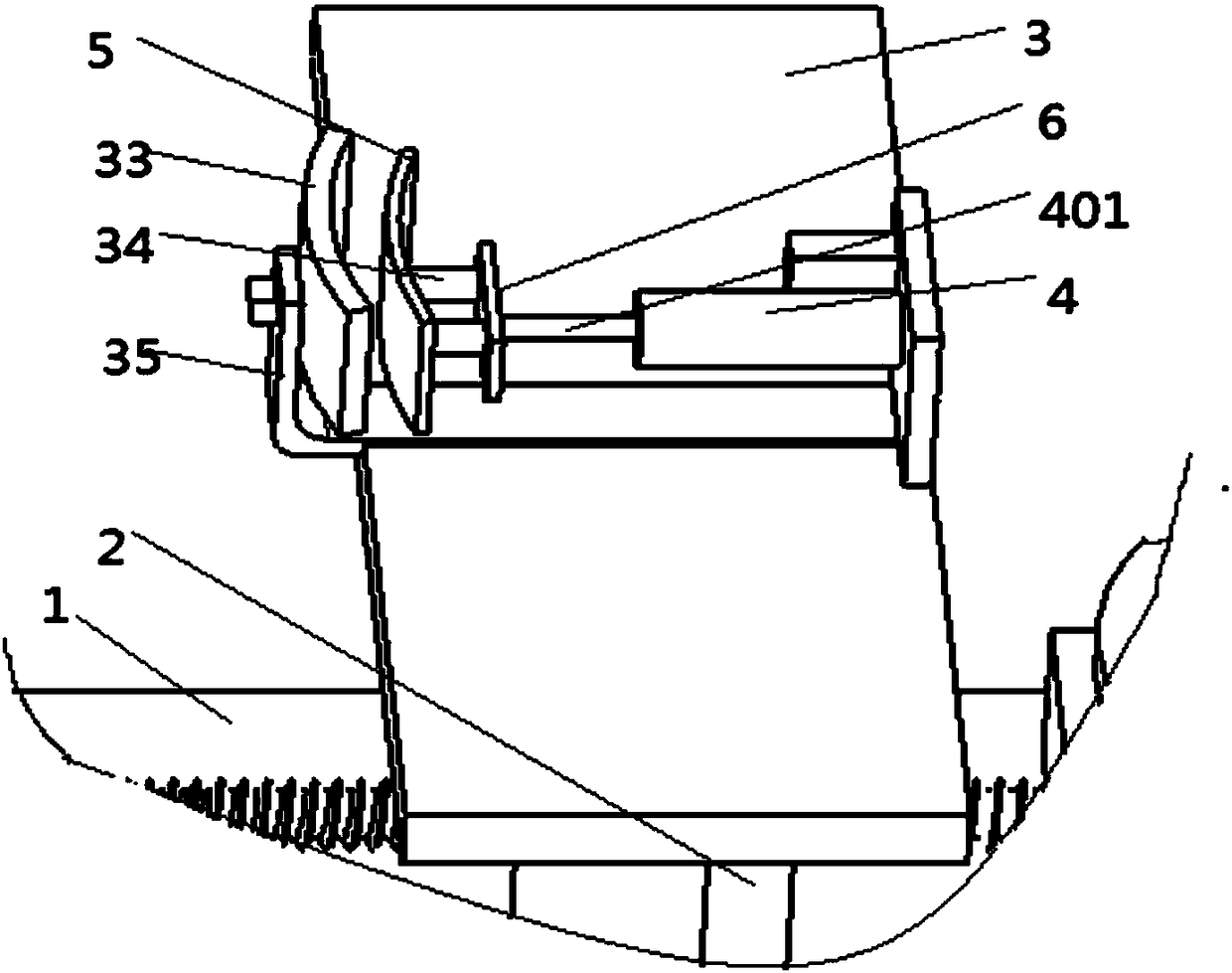

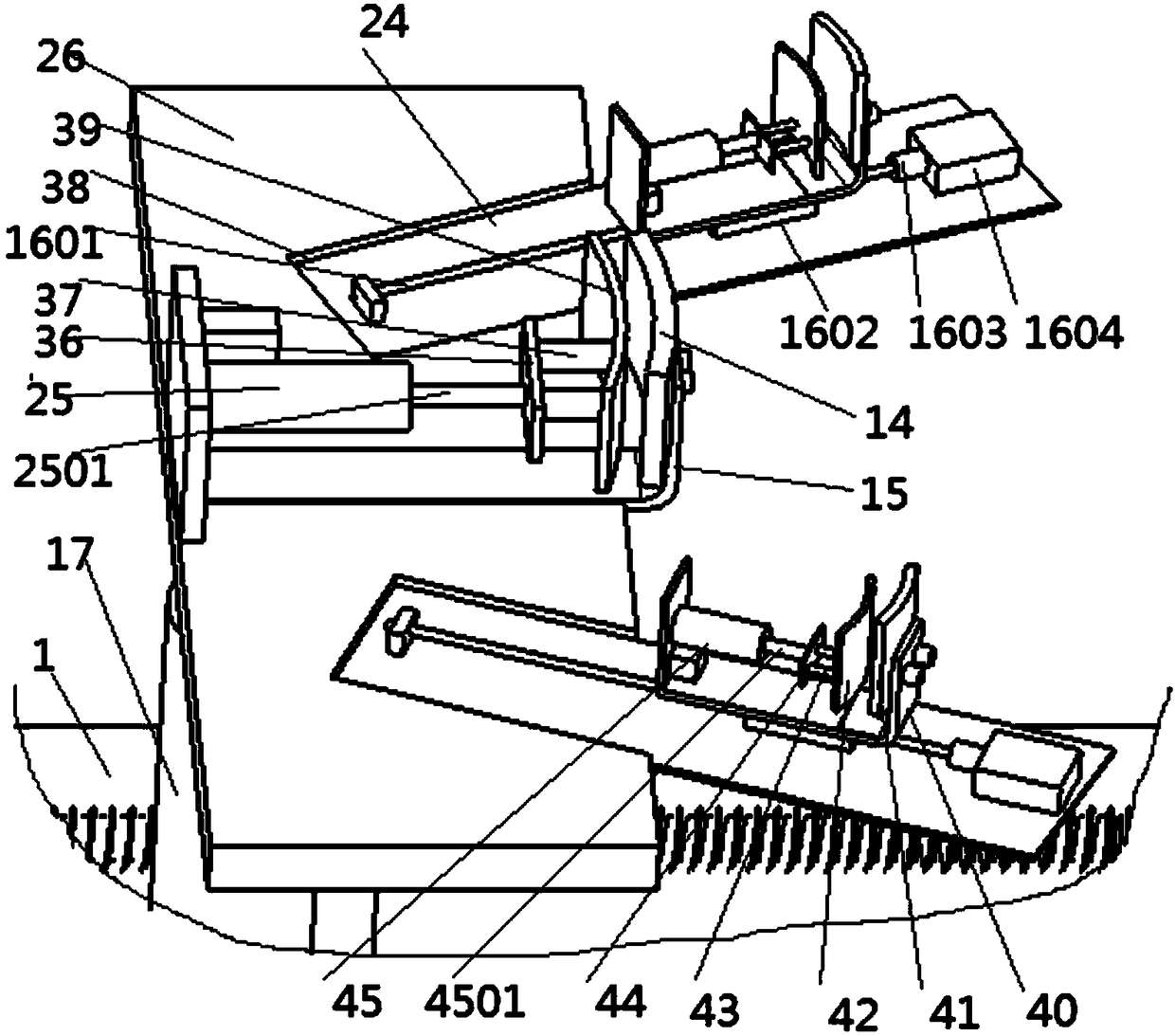

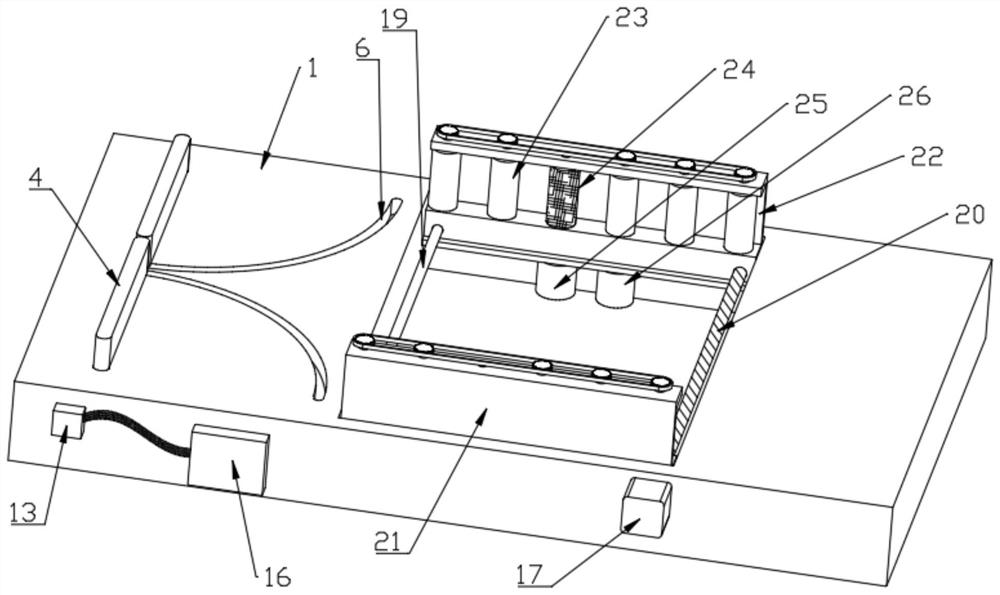

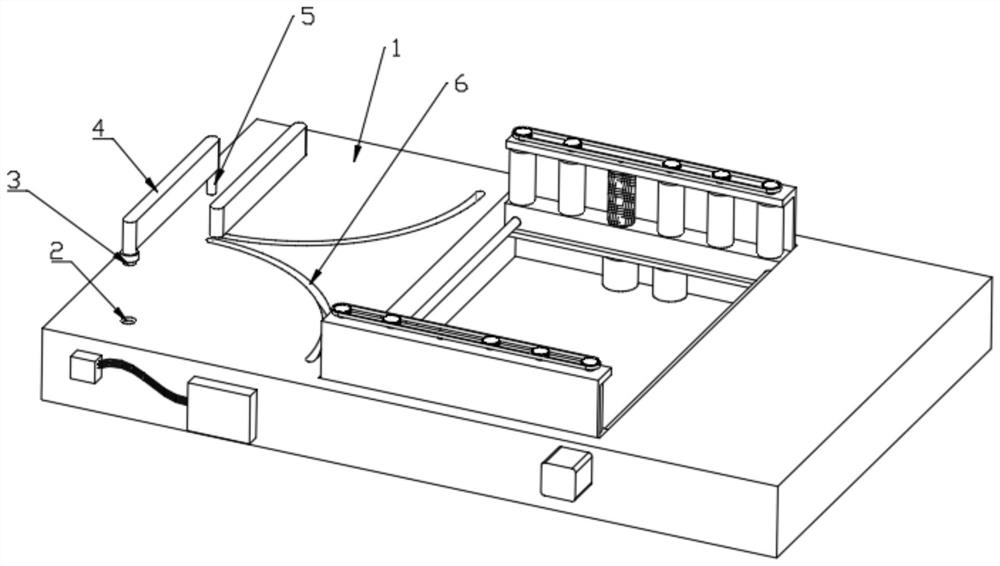

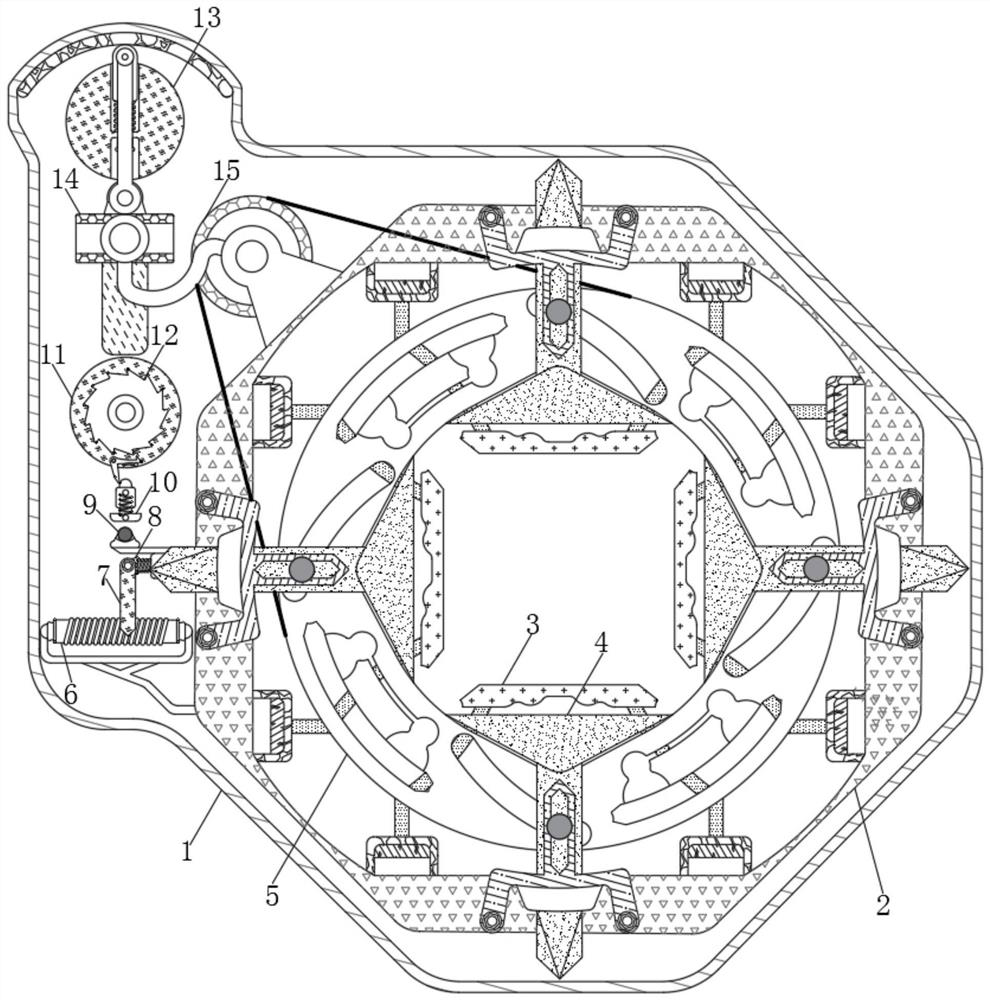

Equipment for processing musical instrument bags

InactiveCN108237580ASolve the problem of difficult processing and low efficiencyEasy to punchMetal working apparatusEngineeringCantilever

The invention provides equipment for processing musical instrument bags. The equipment comprises a base and two drilling and trimming mechanisms arranged on the base in a mirror symmetry mode. A clamping mechanism is arranged between the two drilling and trimming mechanisms. Each drilling and trimming mechanism comprises a support, and the support arranged on each drilling and trimming mechanism is slidably connected with the base through a first sliding mechanism. A first rotation mechanism is further arranged between each first sliding mechanism and the corresponding support. Cantilevers arerotationally connected with the side walls of the supports through second rotation mechanisms. Drilling and trimming assemblies are slidably connected with the cantilevers through second sliding mechanisms. The minimum distance between the edges of the cantilevers and the clamping mechanism is greater than or equal to 10 mm. According to the equipment for processing the musical instrument bags, the irregular bags are drilled and trimmed through the special clamping mechanism and the drilling and trimming mechanisms, drilling of curved side walls is rapid and convenient, the assembling efficiency can be improved through the clamping mechanism when the bags are assembled, and the problem that the musical instrument bags are difficult to process and low in efficiency is solved.

Owner:TIANJIN JINAOLIN LUGGAGE CO LTD

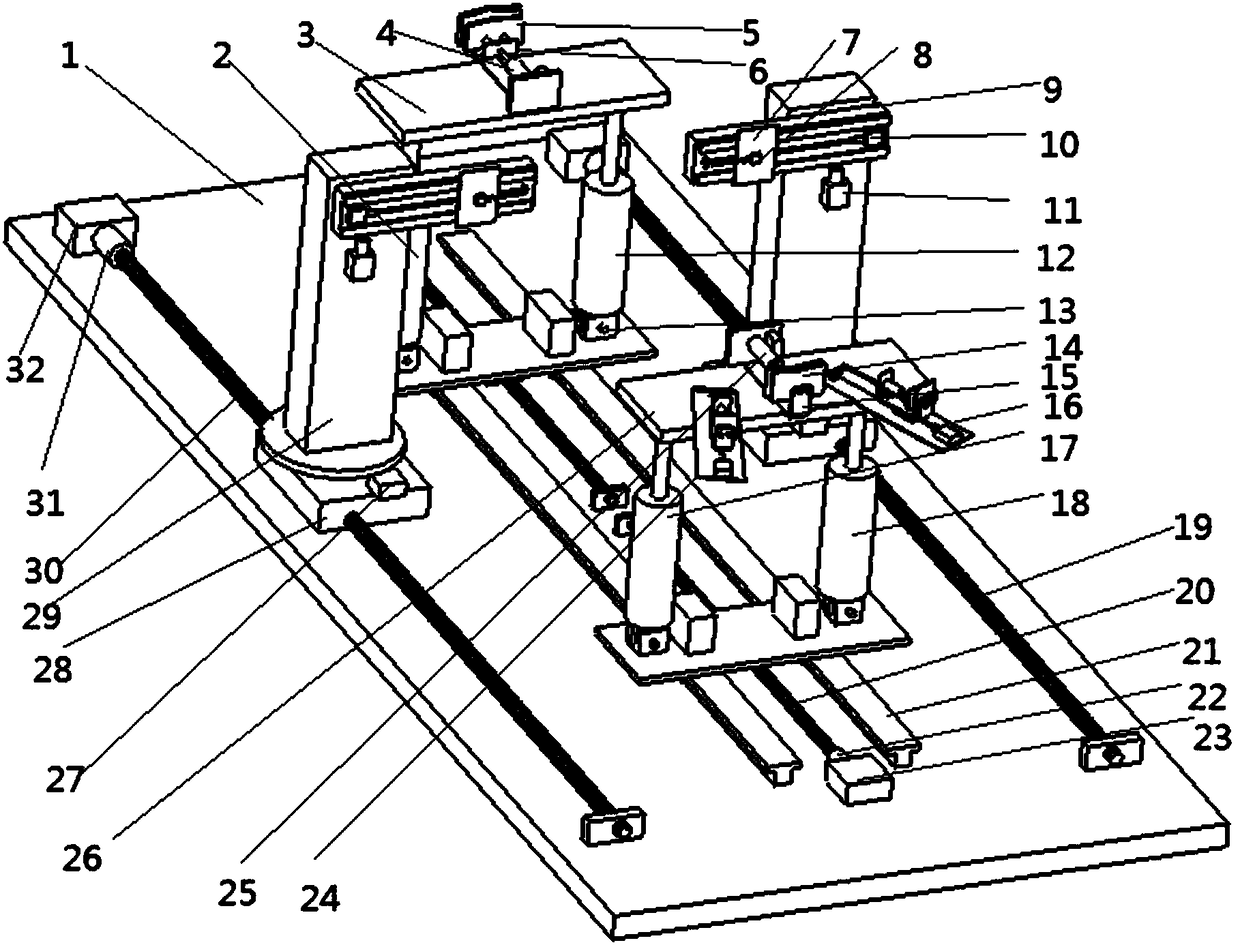

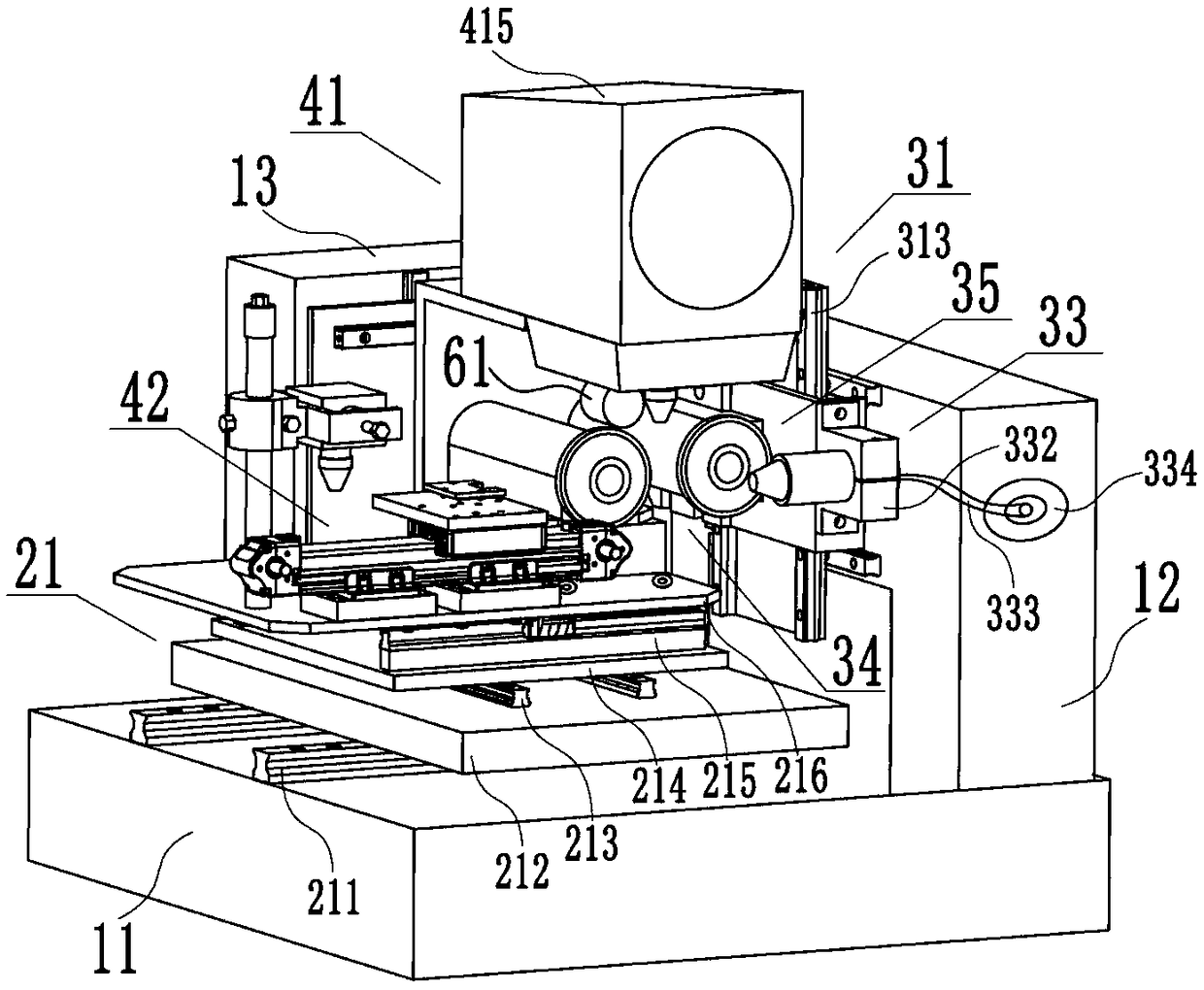

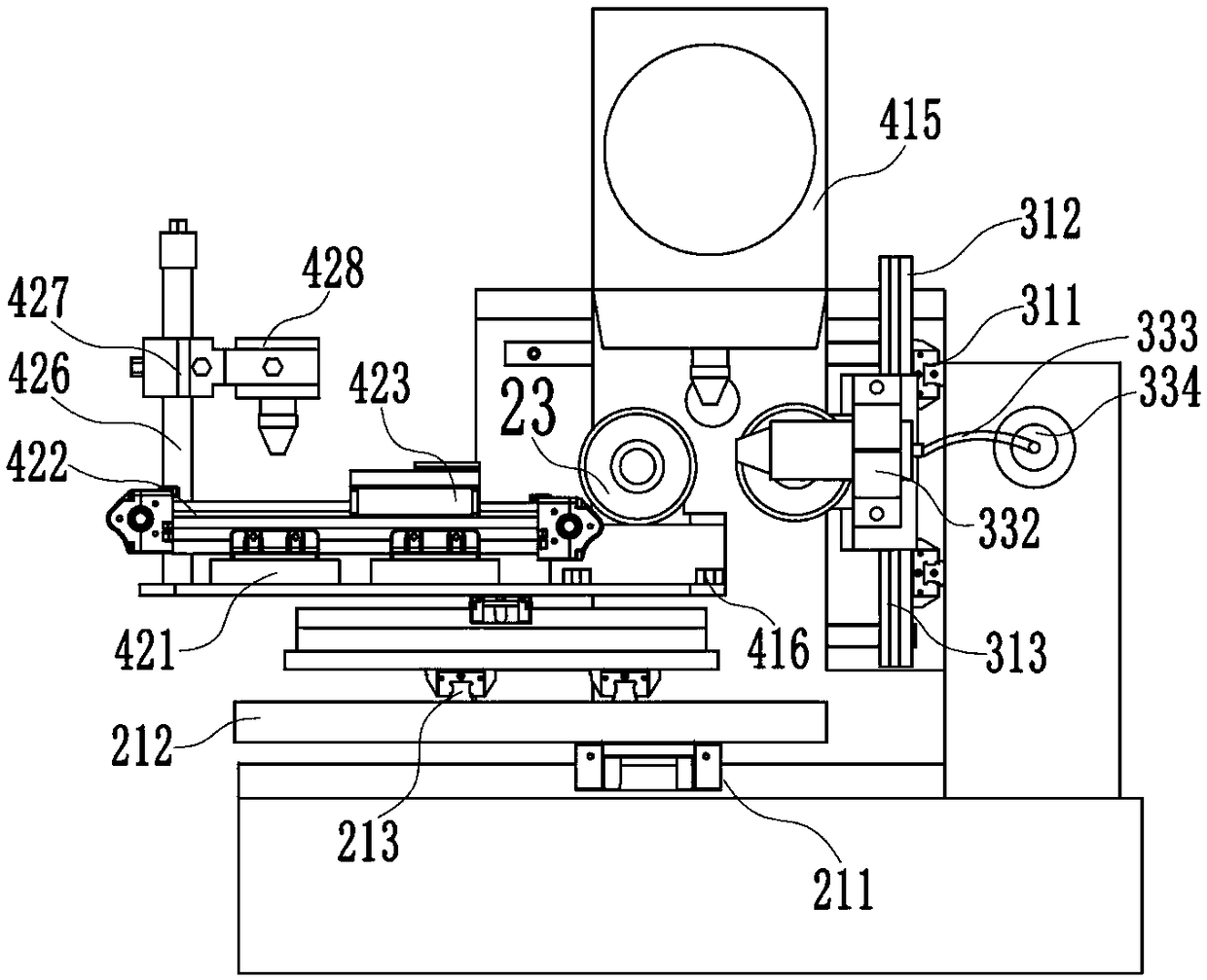

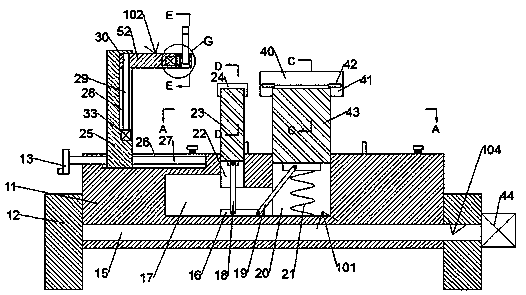

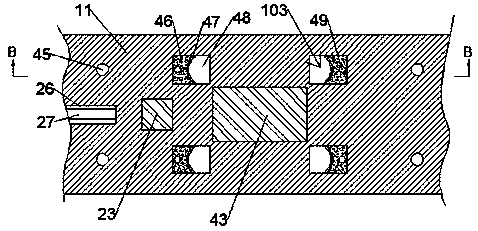

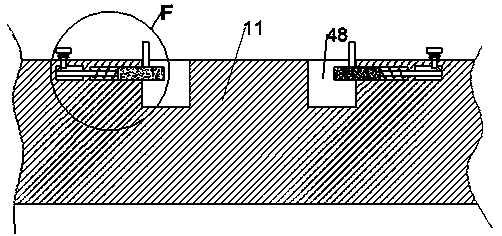

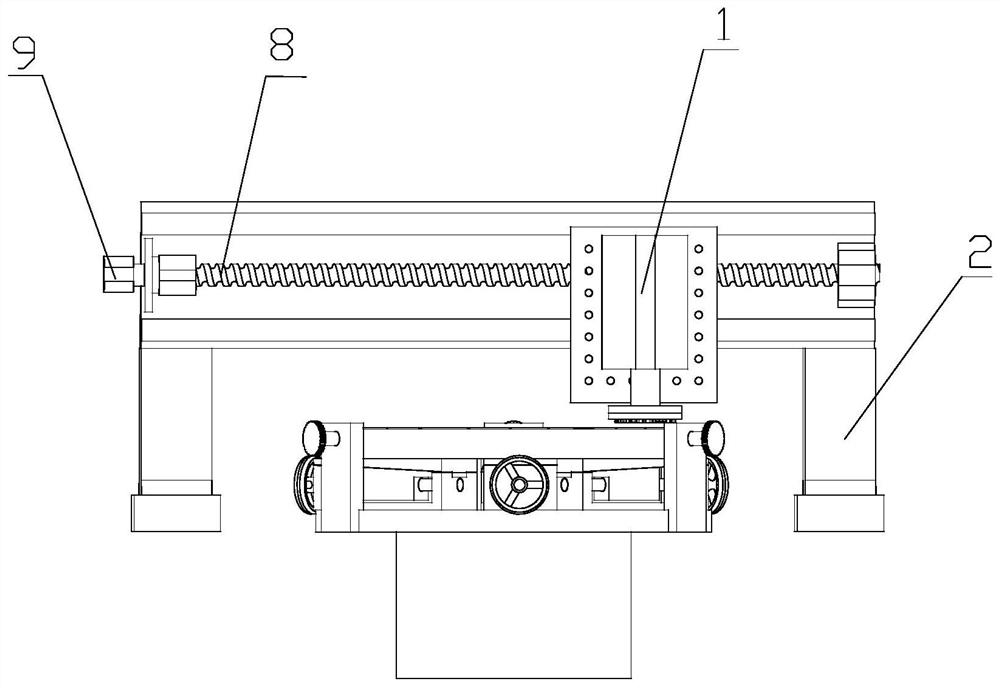

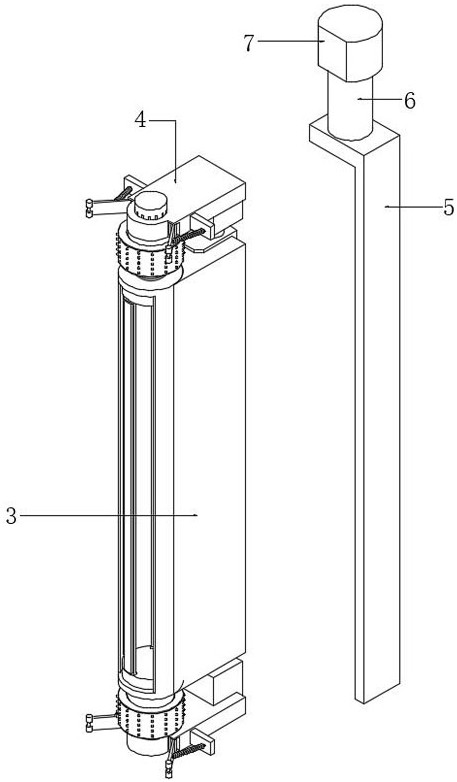

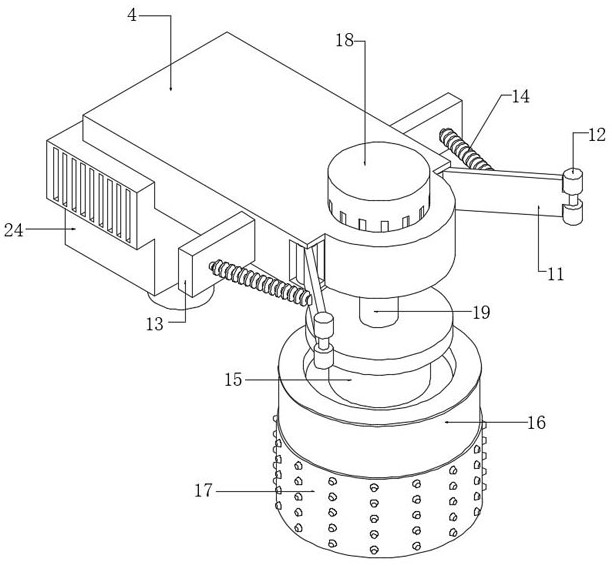

Universal automatic composite abrasive wheel trimming machine

ActiveCN108747823ALow costLow efficiencyGrinding feed controlAbrasive surface conditioning devicesDevice MonitorEngineering

The invention relates to a universal automatic composite abrasive wheel trimming machine. The trimming machine comprises a workpiece work mechanism, a trimming mechanism, a detection mechanism and a motion control mechanism. The workpiece work mechanism adjusts an abrasive wheel to the position needed for trimming. The trimming mechanism comprises a trimming feeding device, a main shaft S2, a laser trimming device, an electric spark trimming device and a mechanical trimming device. The laser trimming device, the electric spark trimming device or the mechanical trimming device moves to the position needed for trimming to trim an abrasive wheel. The detection mechanism comprises a projection monitoring device and a repeated reflection detection device. The projection monitoring device monitors trimming of the abrasive wheel in real time. The repeated reflection detection device conducts online repeated reflection method detection on trimming of the abrasive wheel, and the detection result is transmitted to the motion control mechanism. The motion control mechanism controls the actions of the workpiece work mechanism, the trimming mechanism and the detection mechanism according to thejudgment result. The universal automatic composite abrasive wheel trimming machine is low in cost, high in efficiency and precision, wide in adaptability, high in automation degree and simple in operation.

Owner:湖南镭盛机电科技有限公司

Tree shape and pruning method of three-main branch peach tree

ActiveCN109220304AShort forming timeHigh light efficiencyCultivating equipmentsHorticulture methodsMain branchTree shaped

The invention discloses a tree shape and pruning method of a three-main branch peach tree. The tree is 2.4-2.6m high and the trunk is 30-40cm high; three uniformly distributed main branches are left in the trunk outside the south; the angle between the adjacent main branches is 110-130 degrees, and the angle between each main branch and the trunk is 50-55 degrees; the base of each main branch is respectively provided with a permanent branch, and each main branch is provided with a bearing branch. The tree shape of the invention has the advantages of short forming time, high light efficiency, premature delivery, high yield and stable yield. Due to the sufficient illumination of fruits, the tree body is robust, the flower bud is full, the yield is stable and the fruit quality is good. Sincethe main branches grow with small inclination and the overall height is not high, people is convenient to stand on the ground to perform pruning and fruit picking, and inter-row mechanical operation can also be achieved. Meanwhile, the pruning method is simple to operate, easy to master, and can be quickly popularized.

Owner:濮阳市林业科学院

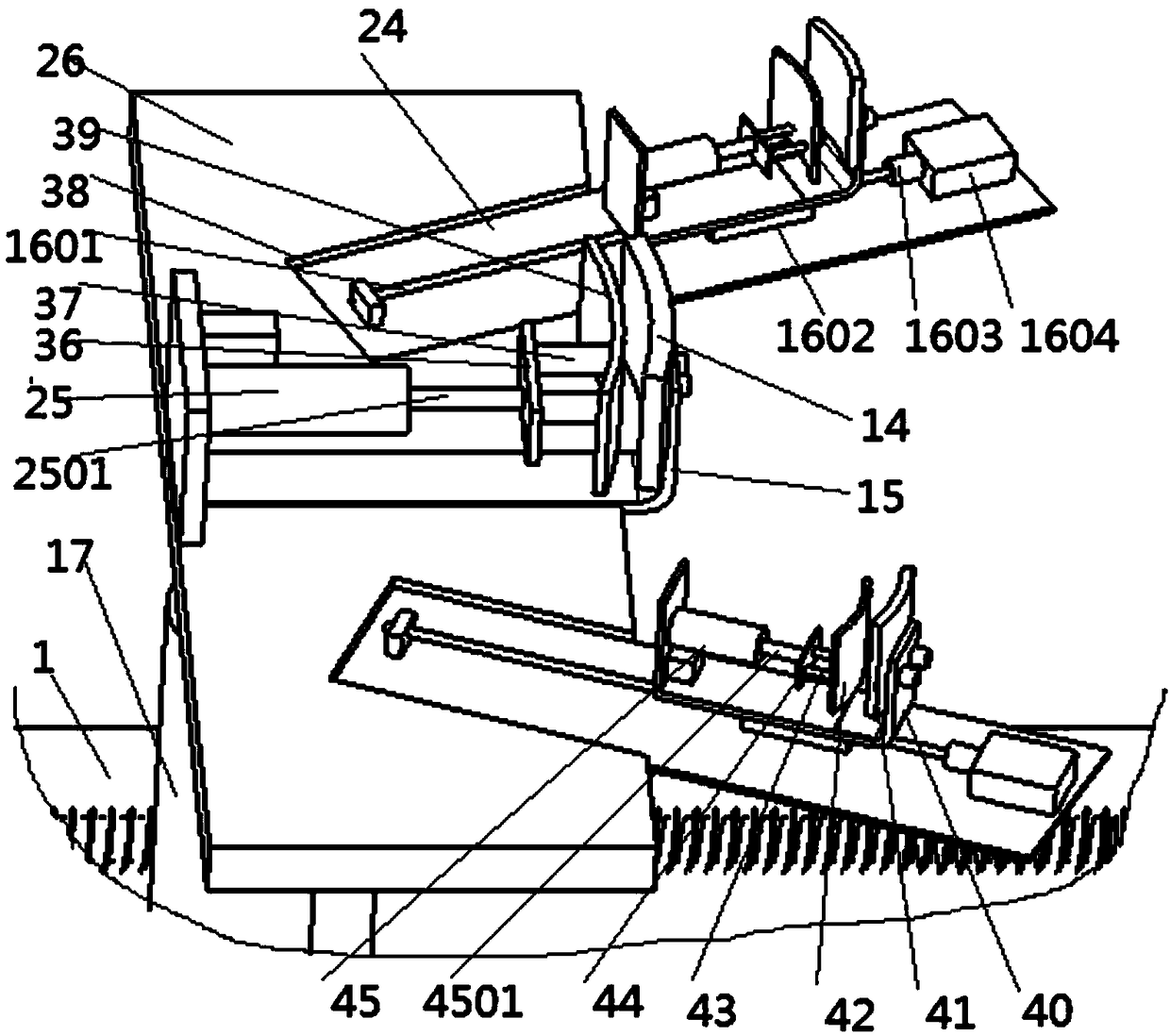

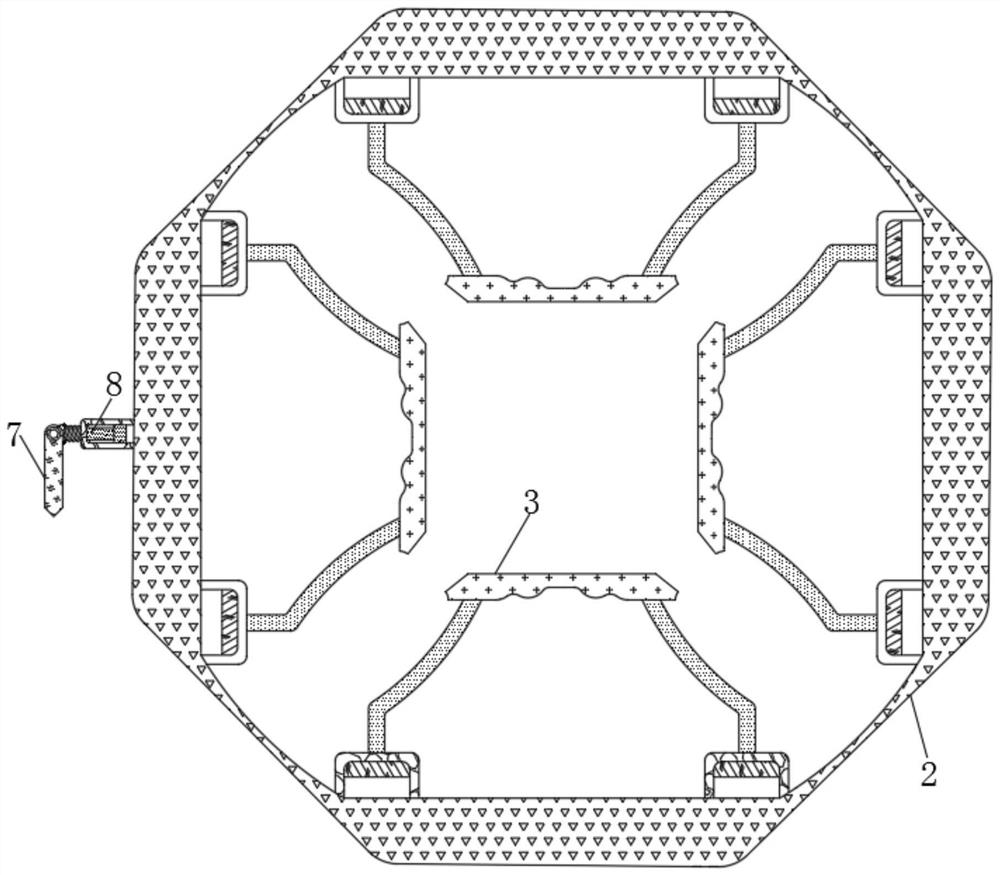

Wool trimming fixing device based on animal husbandry

InactiveCN110235798AEasy trimmingEasy to trimOther apparatusTaming and training devicesSemi automaticEngineering

The invention relates to a wool trimming fixing device based on animal husbandry. The device comprises a main device body, the main device body is internally provided with a lifting cavity with an upward opening, the inner wall of the lifting cavity is slidingly provided with a first sliding column, and the top surface of the first sliding column is fixedly provided with a placement platform capable of being used for supporting the body of a sheep; the left side of the lifting cavity is provided with a moving cavity with an upward opening, the inner wall of the moving cavity is slidingly provided with a second sliding column, the top surface of the second sliding column is provided with a head frame capable of supporting the head of the sheep, and the lifting cavity and the moving cavity are communicated with a connecting cavity. The wool trimming fixing device based on animal husbandry has the advantages that the wool trimming process in the animal husbandry industry can be more convenient, through the linkage of the device and a semi-automatic mechanism, the possibility that the sheep struggles during wool trimming is reduced, and a wool trimming operator does not need to spend a lot of effort on turning over the body of the sheep.

Owner:FUZHOU MAWEI DISTRICT HAOLI CLOTHING CO LTD

Ready-to-eat buckwheat-meat food and manufacturing process thereof

InactiveCN102599533AReasonable material selectionEasy to choose materialsFood preparationBiotechnologyNutrition

The invention relates to a ready-to-eat buckwheat-meat food and a manufacturing process thereof, which belong to the technical field of ready-to-eat foods and manufacturing processes thereof. According to the invention, through taking 4-7 parts of pigskin, 6-9 parts of chicken, 2-3.5 parts of pig fat and 0.055-0.07 part of black buckwheat as main materials and combining with auxiliary materials, a ready-to-eat buckwheat-meat food is prepared, so that the problems of unreasonable formulas and poor material selecting in the prior art are solved, and a formula and a proportion for reasonably-collocated ready-to-eat buckwheat-meat foods are provided, therefore, a prepared ready-to-eat buckwheat-meat food can be stored for a long time while the flavor of meat is kept, the nutrition structure of the food can be kept, and the efficacy of buckwheat is played well. By using the manufacturing process of the ready-to-eat buckwheat-meat food provided by the invention, the flavor of meat can be kept well, and the efficacy of buckwheat can be played better.

Owner:SICHUAN GAOJIN FOOD CO LTD

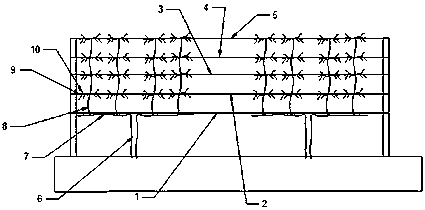

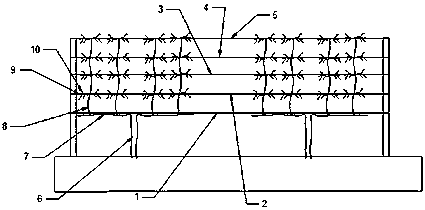

Cylindrical sweet cherry shaping and pruning method applicable to labor-saving operation

ActiveCN110754242ALabor savingTree skeleton is stableCultivating equipmentsHorticulture methodsShootAgricultural engineering

The invention belongs to the technical field of agriculture, and particularly relates to a cylindrical sweet cherry shaping and pruning method applicable to labor-saving operation. The pruning methodparticularly includes the steps: (1) erecting a support; (2) planting biennal seedlings, notching buds to facilitate directional branching, enabling small bearing branch groups to be spirally distributed, continuously removing tops of new shoots, and cutting back the shoots in winter; (3) planting full bearing period trees with 2-3 years old, and pruning the trees according to matched technical measures. A cylindrical sweet cherry shaping and pruning technique for labor-saving operation is provided according to characteristics of Gisela dwarfing stocks, the cylindrical sweet cherry trees pruned by the method has the advantages that framework is stable, light transmission performance is high, each branch can be irradiated, excessive nutrient consumption is avoided, shapes are rapidly formed, high yield is achieved at early stage, high-quality fruit rate is high, the pruning method is simple and easy, fruits are easily picked, labor is saved, and line spacing mechanical operation, high-density cultivation and the like are facilitated by the aid of wide line spacing.

Owner:SHANDONG INST OF POMOLOGY

Two-main-branch natural open-centered peach tree form and forming method

ActiveCN112219636AShort tree forming timeHigh light efficiencySaving energy measuresCultivating equipmentsTree shapedTrunk

The invention provides a two-main-branch natural open-centered peach tree form. The form comprises a trunk, and a first main branch and a second main branch which are opposite in growth and extensiondirection are arranged on the trunk; the first main branch is provided with at least one first main branch first branch and at least one first main branch second branch, and the growth and extension directions of the first main branch first branch and the first main branch second branch on the first main branch are opposite; and the second main branch is provided with at least one second main branch first branch and at least one second main branch second branch, and the growth and extension directions of the second main branch first branch and the second main branch second branch on the secondmain branch are opposite. The invention further provides a forming method of the two-main-branch natural open-centered peach tree form. According to the two-main-branch natural open-centered peach tree form and the forming method, the forming time of the tree form is short, and the two-main-branch natural open-centered peach tree form has the advantages of being high in lighting effect, high in quality, high in yield and stable in yield.

Owner:SHANGHAI ACAD OF AGRI SCI +2

Wearproof cutting device for liquid crystal glass plate processing

InactiveCN109592890ARegulation stabilityStable positionGlass severing apparatusEngineeringMechanical engineering

The invention relates to a wearproof cutting device for liquid crystal glass plate processing. The wearproof cutting device comprises a footstand and a locating and cutting device; the upper end of the footstand is provided with a servo motor, and the upper end of the servo motor is connected with a driving lead screw; the outer side of the middle of the driving lead screw is connected with a driving and positioning seat, and the outer wall of the driving and positioning seat is connected with a central connecting plate; a regulating screw is penetrated and connected to the inside of the leftend of the central connecting plate, and the bottom end of the regulating screw is fixedly provided with a crank; the top end of the regulating screw is connected with a connecting bearing, and the left and right ends of the regulating screw are provided with limiting rods; and a snap device is fixedly arranged above the limiting rods. The wearproof cutting device has the beneficial effects that the wearproof cutting device for liquid crystal glass plate processing is provided with side connecting columns and a bottom snap plate, and a top snap plate can drive the bottom snap plate to slide and regulate when sliding and regulating due to the arrangement of the four side connecting columns, and furthermore, it is convenient to stably regulate and use the movable cutting device by virtue ofa horizontal connecting beam.

Owner:深圳市新世纪拓佳光电技术有限公司

High slender spindle-shaped apple tree form and trimming method thereof

InactiveCN101755655BCrown small and tallStrong result abilityCultivating equipmentsDecapitationUltimate tensile strength

Owner:NORTHWEST A & F UNIV

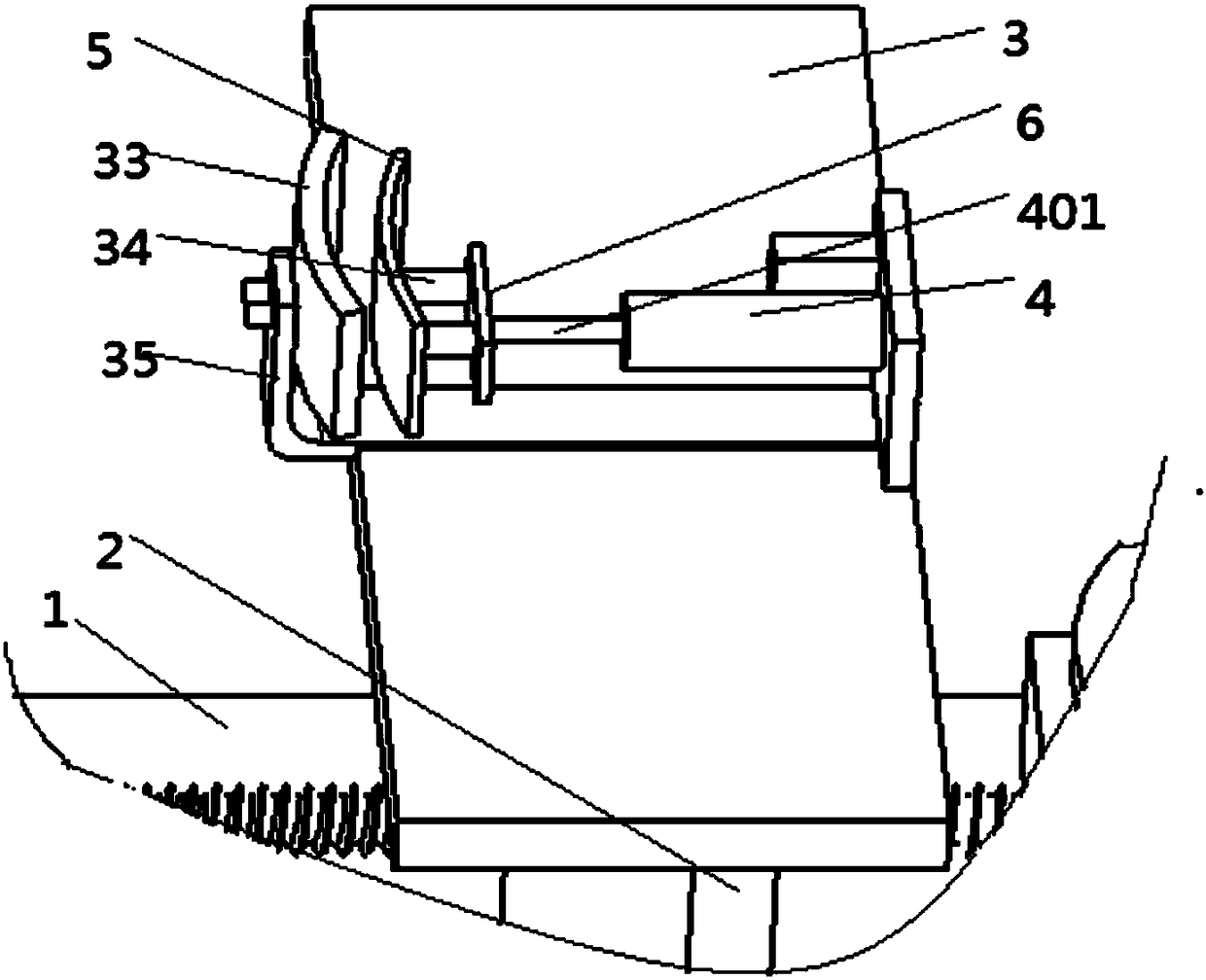

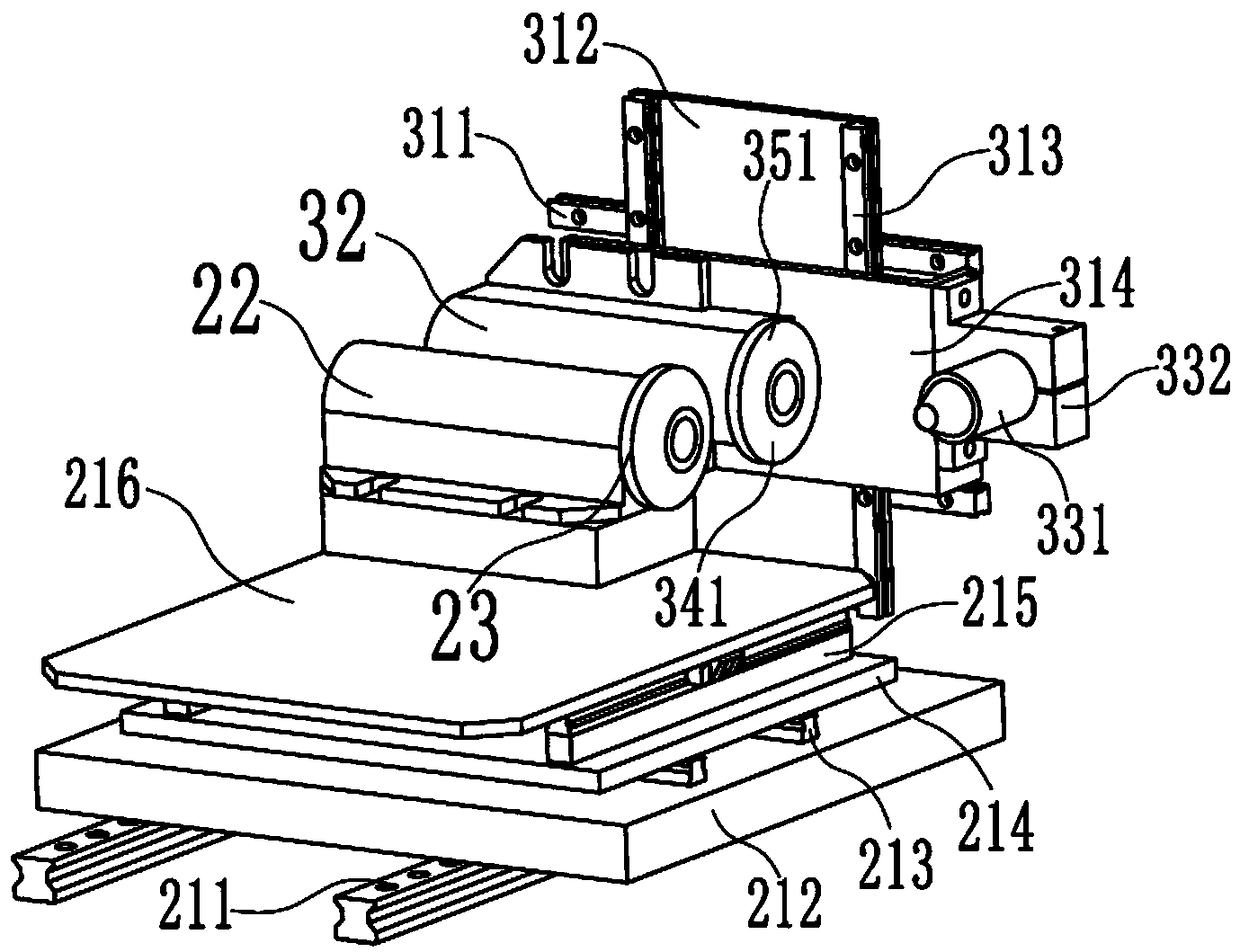

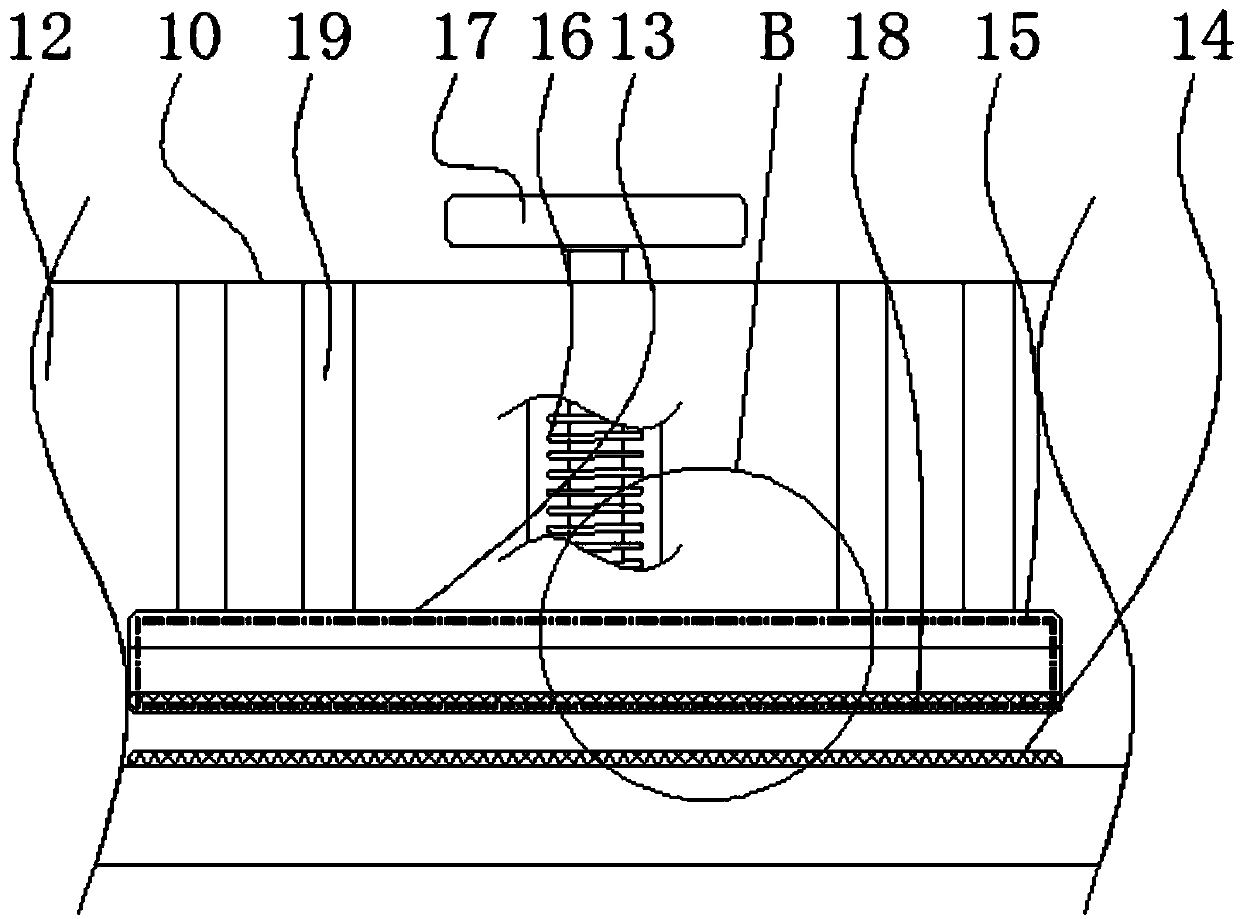

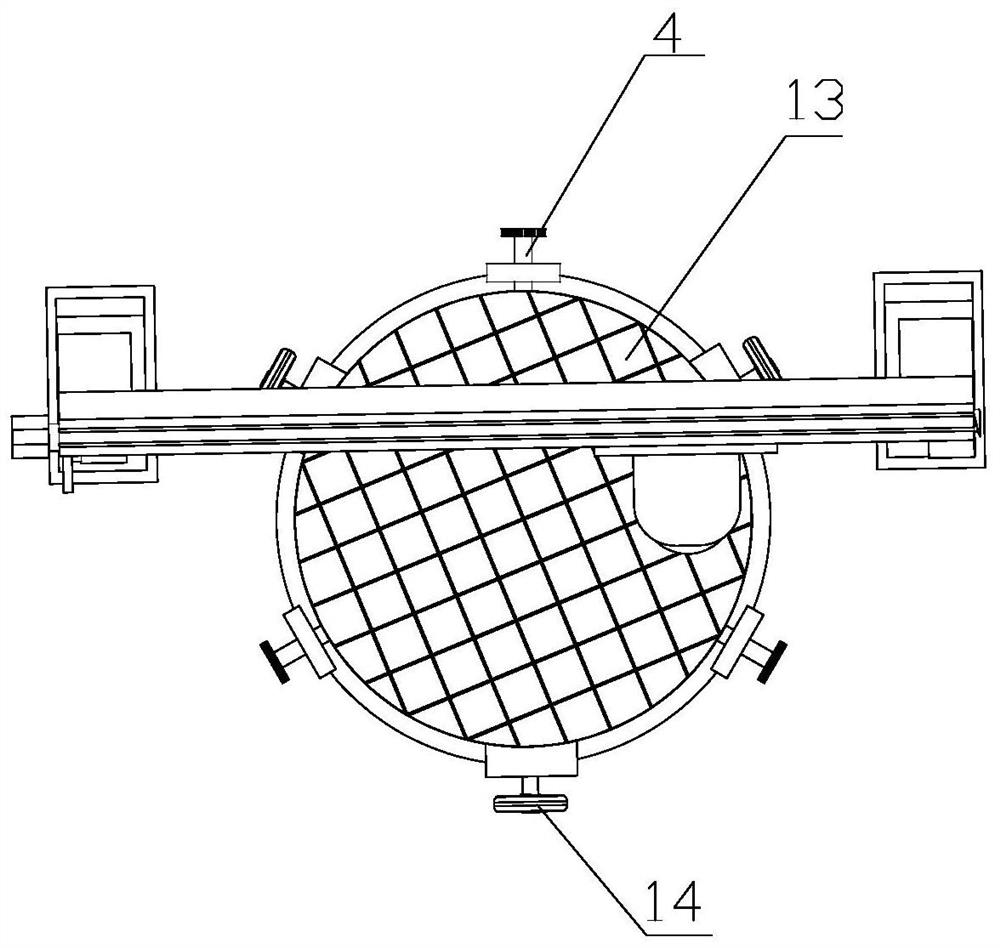

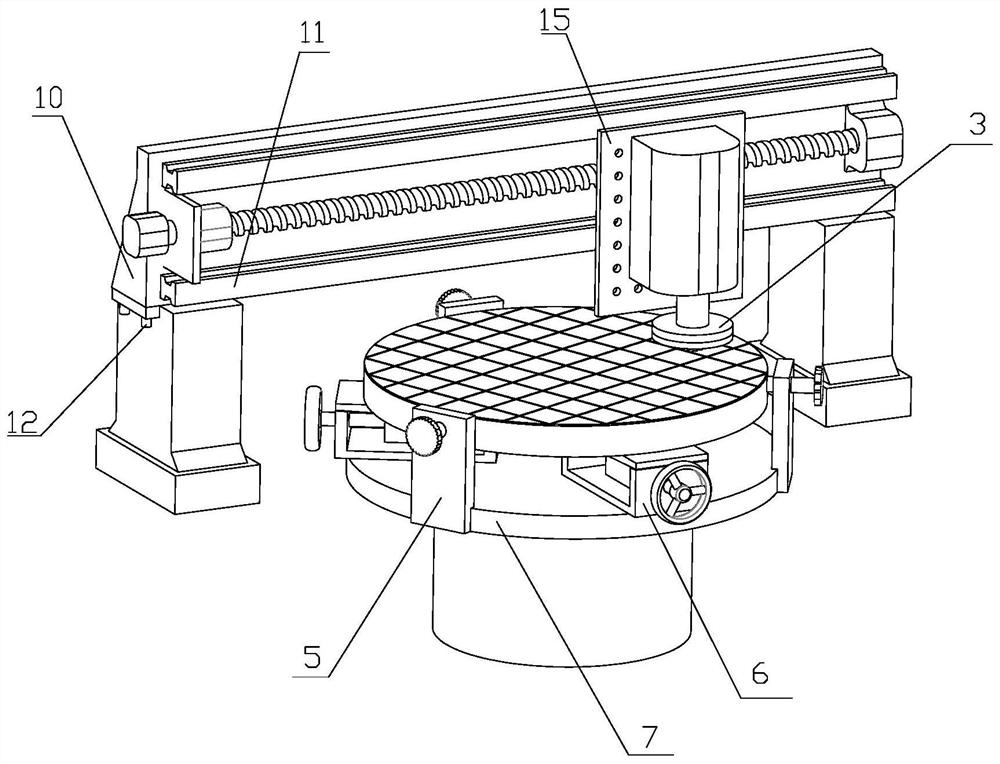

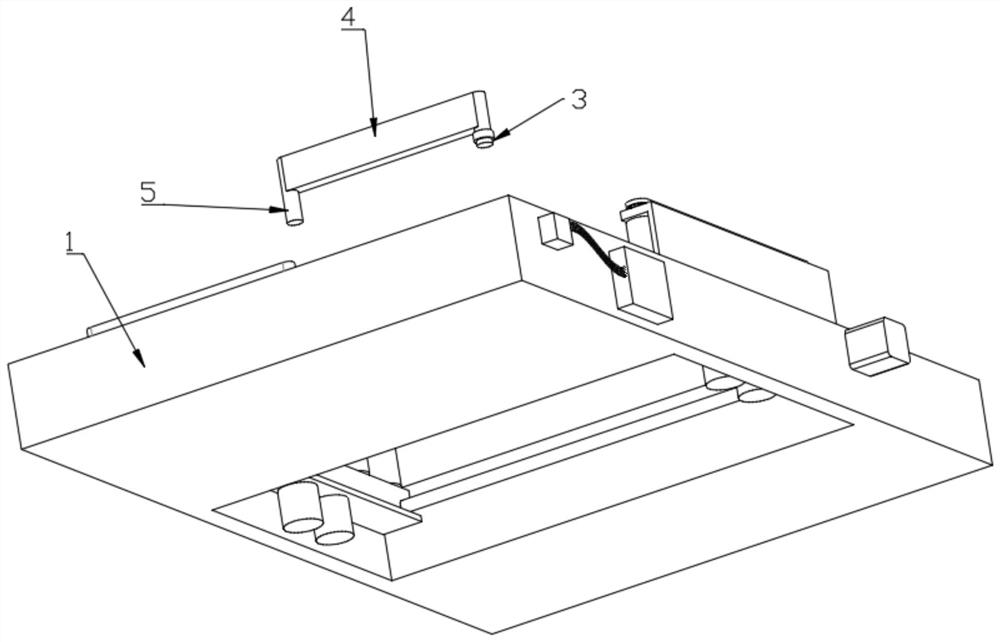

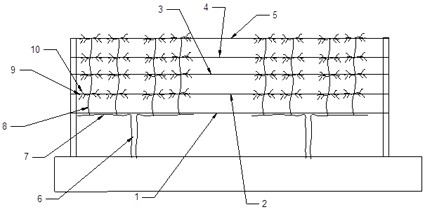

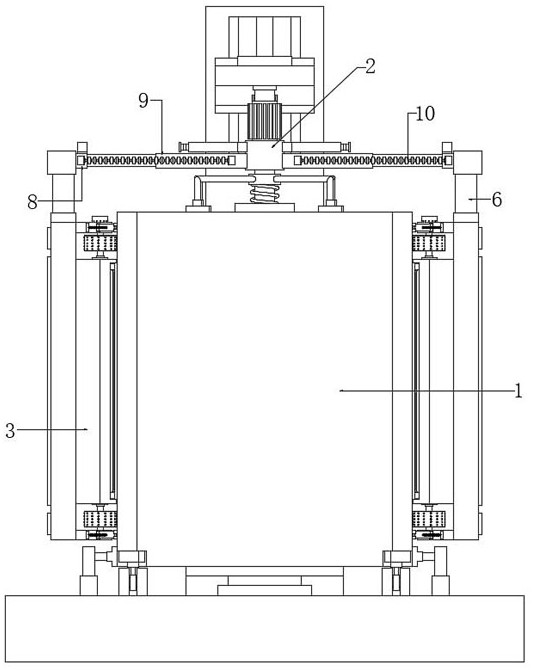

Off-line finishing device and finishing method for polishing discs

ActiveCN112405215AFast and precise trimmingEasy trimmingOptical surface grinding machinesPolishingLinear motor

The invention provides an off-line finishing device and finishing method for large-size polishing discs. According to the off-line finishing device for the polishing discs, a guide rail frame is installed on a support, a lead screw and guide rails are arranged on the guide rail frame in parallel, a finishing shaft box is arranged on an installation plate, the installation plate is arranged on thelead screw, and a horizontal movement motor drives the lead screw to rotate so as to drive the installation plate and the finishing shaft box to horizontally move along the guide rails. A diamond finishing disc is installed at the lower end of the finishing shaft box, a rotating motor for controlling the diamond finishing disc to rotate and a linear motor for controlling the diamond finishing discto move up and down in the vertical direction are arranged in the finishing shaft box, multiple adjusting cushion blocks are arranged on the upper surface of a rotary table, and a rotating handle isarranged on each adjusting cushion block. Multiple supporting plates are fixed to the rotary table and locked through locking screws arranged on the supporting plates. Rapid and precise finishing of the polishing discs of different specifications and sizes can be achieved, the finishing operation is easy, the stability is good, and one finishing machine can meet the finishing requirements of multiple machining devices.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

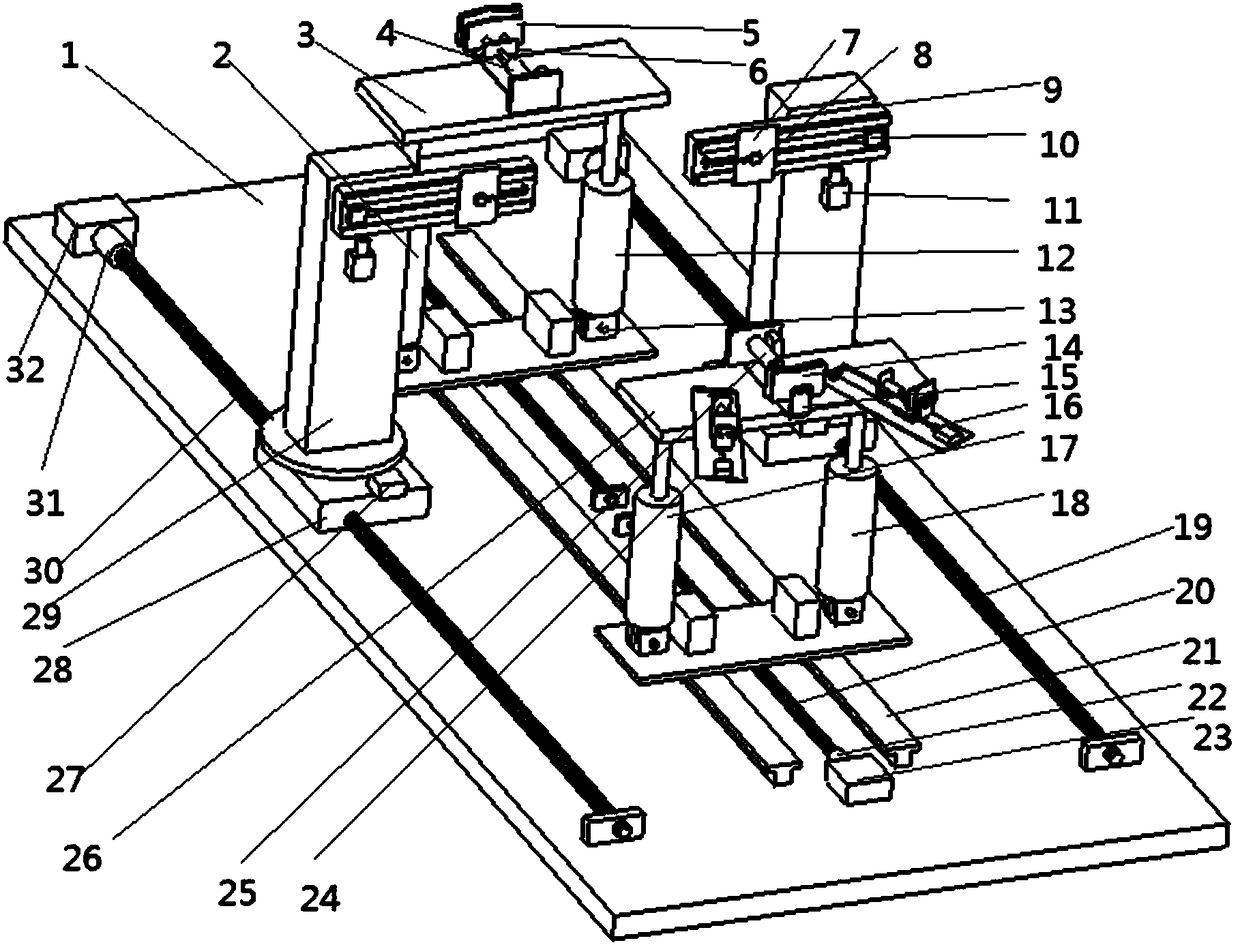

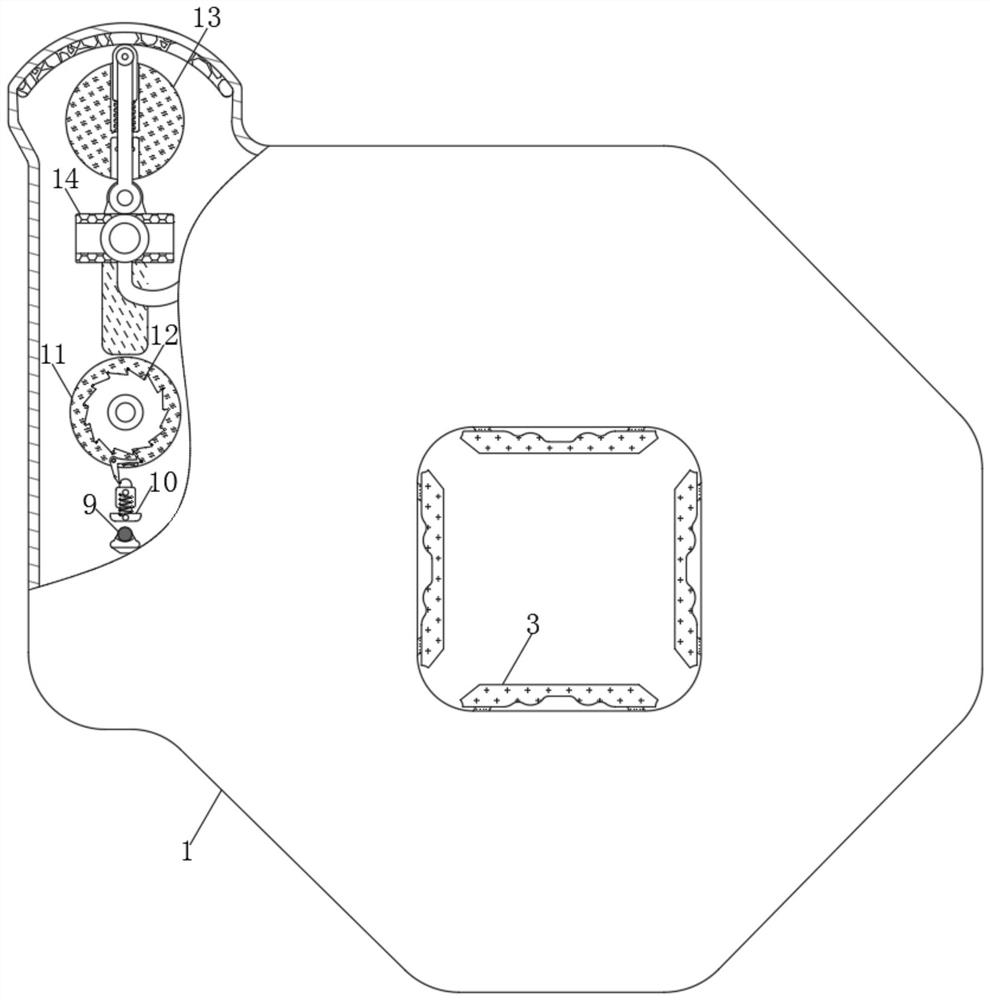

Clamping mechanism for processing musical instrument bags

InactiveCN108237577AEasy to assembleEasy trimmingMetal working apparatusHydraulic cylinderEngineering

The invention provides a clamping mechanism for processing musical instrument bags. The clamping mechanism comprises a first clamping mechanism body and a second clamping mechanism body. The first clamping mechanism body comprises a first hydraulic cylinder, a second hydraulic cylinder and a first workbench. A third hydraulic cylinder is arranged on one side of the first workbench and provided with a first arc-shaped pressing plate and a first arc-shaped fixing plate. The second clamping mechanism comprises a fourth hydraulic cylinder, a fifth hydraulic cylinder and a second workbench which isin spheric joint with the fourth hydraulic cylinder and the fifth hydraulic cylinder. The second workbench is provided with a sixth hydraulic cylinder, a second arc-shaped pressing plate and a secondarc-shaped fixing plate. A third L-shaped support is arranged on the second workbench. A third arc-shaped fixing plate is detachably connected with the vertical side wall of the third L-shaped support. According to the clamping mechanism for processing the musical instrument bags, the irregular bags are clamped and fixed through the clamping mechanism, the assembling efficiency can be improved through the clamping mechanism when the bags are assembled, and the problem that the irregular-shaped musical instrument bags are difficult to clamp and inconvenient to process is solved.

Owner:TIANJIN JINAOLIN LUGGAGE CO LTD

Apple tree shaping and pruning management technique

ActiveCN111096189AEasy trimmingEasy to operateCultivating equipmentsHorticulture methodsAgricultural engineeringPruning

The invention discloses an apple tree shaping and pruning management technique. Planting, main branch determination, pruning and shaping, and a series of fertilizer applying techniques are used, so that apple trees can bloom and bear fruits in two years, the per mu yield of three-year-old apple trees can achieve 1000 kilograms, and the per mu yield of the five-year-old apple trees can achieve 5000-6000 kilograms. The pruning method is simple to operate and easy in popularization.

Owner:王天勇

Red snow pear pruning and shaping method

ActiveCN107646401ACompact treeImprove qualityCultivating equipmentsHorticulture methodsFruit treePear tree

The invention discloses a red snow pear pruning and shaping method. The pruning and shaping method comprises the following steps that 1, according to the site type, the tree form structure is determined; 2, the distances and distribution of branch groups are adjusted; 3, light transmission treatment and ventilation treatment are conducted; 4, different branches are pruned. The invention provides the targeted red snow pear pruning and shaping method. By determining the tree form structure according to the site type, scientifically adjusting the distances and distribution of the branch groups and guaranteeing light transmission and ventilation in cooperation with pruning of the different branches, an obtained red snow pear tree form is compact, the branch groups are reasonably distributed, not only is space effectively used, but also a fruit tree obtains most suitable growth space furthest, light transmission and ventilation are achieved, and on the basis that the fruit setting rate is effectively improved, the quality of red snow pears is greatly improved.

Owner:巍山彝族回族自治县绿源林果有限责任公司 +1

Shaping and trimming method of crowns of pear trees

The invention relates to a shaping and trimming method of crowns of pear trees. The crowns are trimmed into a structure of two layers of main branches, wherein each layer of main branches comprises two main branches facing south and north, and lateral branches are left at two sides of the main branches in the horizontal direction. The shaping and trimming method has the advantages of facilitatingflower bud differentiation, increasing effective photosynthetic accumulation, enhancing wind resistance, and obviously improving the commodity quality of fruit of a single-layer planar pergola shaping method; moreover, the shaping of the crowns is quick; the cultivation of crown structure can be completed to enter the early fruit period 3 years after the planting in general; the yield of a singleplant can be controlled to be 6-10kg, and increases year by year; meanwhile, trimmed crowns do not contain sub-main branches; the trimming method is simple, and is easy to master; the work space of the flower and fruit management of a pear orchard can be controlled; labor and force are saved; the labor efficiency is improved; and the management cost of the orchard is reduced; in addition, the method is suitable for a flat land or a gentle slope landform undulation, and is particularly suitable for a gentle slope with the landform undulation or a slope land with the slope of less than 15 DEG.

Owner:YANGZHOU UNIV +1

Pruning method for rapid peach tree forming

InactiveCN106879389AEasy trimmingGood ventilation and light transmissionCultivating equipmentsHorticulture methodsDiseasePhotosynthetic function

The invention discloses a pruning method for rapid peach tree forming. The method comprises the following specific steps that after a peach tree is subjected to field planting, rapid stem fixing is conducted, wherein the stem height ranges from 50 cm to 60 cm; new shoot bud picking is conducted, when new shoots of the peach tree grow to 30-40 cm, the new shoots need to be uniformly led and tied to the frame surface, the new shoots need to be led and tied 3-4 times along with continuous growth of the new shoots from the early blooming stage to the full-bloom stage, and pinching is conducted on fruited new shoots; before pruning is conducted, watering is conducted on seedlings once, a main tendril is determined according to the thicknesses of tendrils, the cut length is 75-80 cm, and all auxiliary shoots are cut out; diseased leaves of the peach tree are picked off, infection is prevented from spreading, old leaves losing the photosynthetic function are picked off, ventilation and light transmission are promoted, and diseases are reduced. The peach tree pruning method is simple, the framework is clear, the peach tree obtained after pruning is good in ventilation and light transmission conditions, the tree body can be prevented from vigorously growing outwards and upwards, and then the purposes of early yield, high yield and stable yield of the peach tree are achieved; by means of the pruning method, the survival rate of the peach tree can be effectively increased, and the planting cost is lowered.

Owner:金寨胜达农业科技有限公司

Intelligent robot edge trimmer

InactiveCN112828710AEasy trimmingEasy to trimEdge grinding machinesGrinding drivesControl engineeringElectric machinery

The invention discloses an intelligent robot edge trimmer in the field of wood trimming. The intelligent robot edge trimmer comprises a working platform, two rotating grooves are formed in the upper end face of the working platform, the two rotating grooves are symmetrically installed front and back, rotating shafts are rotatably installed in the rotating grooves, baffles are fixedly installed on the upper end faces of the rotating shafts, and sliding rods are fixedly installed on the sides, away from the rotating shafts, of the lower end faces of the baffles; two arc sliding grooves are formed in the upper end face of the working platform in a front-back symmetrical mode, two mounting frames are symmetrically installed in a rectangular groove, and grooves are formed in the opposite sides of the two mounting frames; and conveying cylinders and grinding cylinders are installed in a plurality of rotating holes correspondingly, a second motor and a third motor are fixedly installed on the lower end faces of the mounting frames, an output shaft of the second motor is fixedly connected to the lower end of the grinding cylinders, and an output shaft of the third motor is fixedly connected to one of the plurality of conveying cylinders. According to the device, trimming operation is more convenient and simpler, the working efficiency is improved, the requirement for the technology is reduced, and the applicability is higher.

Owner:苏州颖视智能科技有限公司

A kind of plastic pruning method of plum tree and apricot tree

ActiveCN111108949BIncrease productionSmall footprintCultivating equipmentsHorticulture methodsFruit treeAlcohol sugars

The invention relates to the technical field of fruit tree cultivation, in particular to a method for shaping and pruning plum trees and apricot trees. The present invention proposes a method for shaping and pruning plum trees and apricot trees. The first year of growth: the seedlings are planted in autumn or early spring, and the first-level main branches are cultivated; the first-year dormant period: the second-level main branches are cultivated; Second-year dormancy period: cultivate side branches; third-year growth period: side branches are finalized; third-year dormancy period: cultivate fruiting branches; first-level main branches, second-level main branches and weak branches that are too dense on side branches grow from the base Thinning, leaving 2 to 5 cm shorter than 1 / 2 of the thickness of the growing branches; the fourth growth period: Spray potassium dihydrogen phosphate and sugar alcohol boron once in June and July, and differentiate flower buds in summer, and bear fruit in the next year; Four-year dormant period: maintain the tree shape, remove excessively prosperous and dense branches that disturb the tree shape, and ensure that the thickness of the branches decreases step by step. This pruning method can make full use of the three-dimensional space, save land resources, and is easy to manage.

Owner:SICHUAN AAS HORTICULTURE RES INST

Motor strip line bar intrastrand line changing pattern weaving defect part repairing method

InactiveCN102013768BGuaranteed to be smoothGuaranteed clearanceManufacturing stator/rotor bodiesElectric machineStructural engineering

The invention relates to a motor strip line bar intrastrand line changing pattern weaving defect part repairing method. The invention is characterized in that the method comprises: a filler is made into paste, a strip line bar is horizontally placed on a platform surface and clamp plates are respectively clamped by virtue of flanges, the strip line bar defect part is filled with the filler, and abamboo chip is utilized to strickle the filler; the strip line bar filling part is wound and strengthened by a polytetrafluoroethylene belt; and curing is carried out, and then a file and sand paper are utilized to polish the filling part. The invention has the advantages that measurement of the repaired motor strip line bar intrastrand line changing pattern weaving defect part is almost the samewith other parts, the repaired part has no geometrical deformation and is pressureproof, the strip line bar is ensured to be smooth an have no gap, appearance is beautiful, insulation filling of the pattern weaving defect part is full and no intrastrand short circuit phenomenon is caused, and the electrical property is stable. The method provided by invention is simple in repairing operation and can be used for greatly improving the production efficiency.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

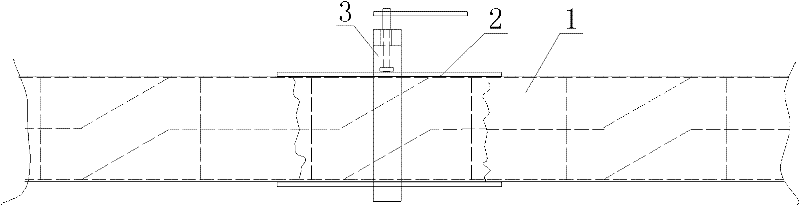

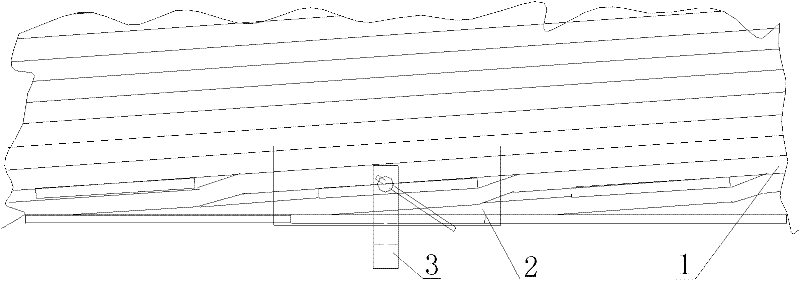

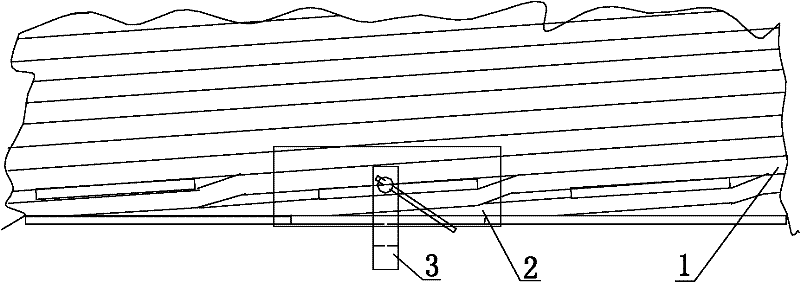

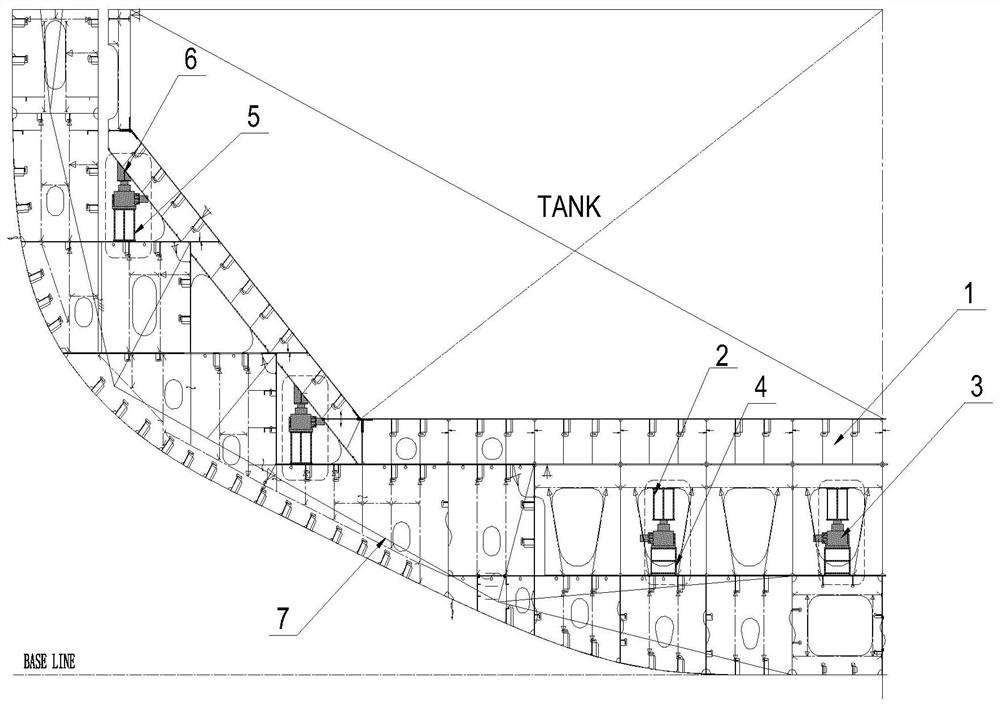

Accurate positioning method for ship single shell block on wharf

The invention discloses a method for accurately positioning a ship single shell block on a wharf. The method comprises the following steps that firstly, before the single shell block is hoisted, a jacking bracket is fixedly installed on the back face of an inclined side plate; secondly, a manhole is formed in the transverse bulkhead of the original ship; thirdly, jacking lower cross beam installation lines are drawn on the double-layer bottom and the broadside platform of the original ship correspondingly; 4, lifting the jacking lower cross beam from the large hatch and placing the jacking lower cross beam in place according to the mounting line; fifthly, a jacking device is placed on the jacking lower cross beam; sixthly, the single-shell block is hoisted into the large cabin; seventhly, a jacking upper cross beam at the double-layer bottom is moved in from a manhole of the transverse bulkhead; and 8, the floating crane is used for adjusting the single shell block in place, the single shell block is arranged on the jacking upper cross beam, and the jacking device is used for adjusting the position of the single shell block. The cross beam is in contact with the ship body structure, so that the deformation of the structure can be greatly reduced, and the subsequent field workload is reduced.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

Chinese wolfberry tree pruning method

The invention discloses a Chinese wolfberry tree pruning method. The Chinese wolfberry tree pruning method comprises the steps that the height of an upright main trunk above the ground of a Chinese wolfberry tree is pruned to 110-150 cm; a first layer of flat inclined main branches and a second layer of flat inclined main branches are sequentially selected from bottom to top along a main trunk ofthe Chinese wolfberry tree, and four flat inclined main branches are reserved on each layer; all other branches below the first layer of flat inclined main branches and on the main trunk between the first layer of flat inclined main branches and the second layer of flat inclined main branches are pruned; the branches on the first layer of flat inclined main branches and the second layer of flat inclined main branches are selected and pruned, messy branches are pruned, so that the number of fruiting mother branches on the whole tree is controlled to be 30-50, the number of the whole tree of annual fruiting branches is controlled to be 100-180, and the number of the whole tree of biennial fruiting branches is controlled to be 5-15; and during pruning, the diameter of the fruiting mother branches away from roots of the branch by 2 cm is controlled to be 4 mm or above, and the diameter of the biennial fruiting branches away from the roots of the branches by 2 cm is controlled to be 2 mm orabove.

Owner:中宁县百瑞源枸杞产业发展有限公司 +1

Winter pruning method for annual branches of apple tree

PendingCN112470810ATo achieve the purpose of pruningReach operationCultivating equipmentsHorticulture methodsFruit treeAgricultural engineering

The invention relates to the field of fruit tree pruning methods, and particularly discloses a winter pruning method for annual branches of an apple tree. The method comprises the following steps of performing inter-row intermediate cutting, opening a ventilating duct, performing intermediate cutting to open the plant spacing, opening illumination of a tree body, screening permanent main branches,thinning large branches, and pruning the large branches and main branches. According to the method, the annual branches are classified; basically-fixed pruning methods, namely, pruning modes and standards, are defined for all types of the branches; the purpose of pruning is achieved through standardized pruning; the method is easy to learn and operate, the pruning effect is good, and the labor and effort are saved; and secondary pruning is basically not needed after winter pruning or even summer pruning is not needed.

Owner:赵云娟

Trimming device for solving problem of irregular shape of insulating layer of square tube

The invention relates to the technical field of electric power, and discloses a trimming device for solving a problem of an irregular shape of an insulating layer of a square tube. The trimming device comprises a shell, wherein an air ring is fixedly connected to the interior of the shell. Through the combined action of the air ring, a detection mechanism, an insulating tube, a metal slip sheet, an ejector rod, an electromagnet, a brake rod, a first rotary disc and a ratchet wheel, heating operation is automatically triggered by utilizing a bulge on the surface of a cable, so that the bulge of the insulating layer is broken by heating, the trimming operation is facilitated, the trimming operation is started, the linkage between structures is improved, the operation is convenient and fast, and the automation degree is high; and through the combined action of a second rotary disc, a sliding plate, a third rotary disc, a pressing tool and a ring plate, the four faces of the cable are extruded automatically, the other faces of the cable are supported while the insulating layer face where the bulge exists is flattened, the situation that the cable is distorted due to non-uniformity is effectively avoided, and the trimming quality is guaranteed.

Owner:朱宽雄

A trimming device and trimming method for the production and processing of bags

The invention belongs to the technical field of luggage processing, in particular to a trimming device and a trimming method for the production and processing of luggage. In view of the current luggage processing process, when trimming the outer wall of the luggage, the cutting and trimming equipment needs to be constantly Adjust the position so that the edge trimming output position can always fit the box wall of the luggage, so the device will stop during the trimming operation, the trimming process of the luggage is not smooth, and the trimming time of the luggage is increased. The following plan is proposed , including a luggage body, a functional seat is arranged above the luggage body, and trimming boxes are arranged on both sides of the luggage body, and cushion blocks are arranged on both upper and lower sides of the trimming box. The present invention utilizes the functional seat to drive the edge trimming box to rotate. With the change of the position, the retractable spring stretches or shrinks, and the telescopic rod changes the telescopic state. Adjust the position of the trimming box separately.

Owner:南通市春晖箱包有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com