Motor strip line bar intrastrand line changing pattern weaving defect part repairing method

A strip wire and part technology, which is applied in the field of repairing defective parts of braided flowers by changing wires between strands of a motor strip wire rod, can solve the problems of uneven crossing parts of braiding, cumbersome processing procedures, and inability to achieve supplementary effects, etc. Provides the effects of production efficiency, simple trimming operation, and stable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The method for repairing the defective part of the wire-changing braiding pattern between the strands of the motor strip wire rod is characterized in that it includes the following steps:

[0018] 1) Preparation of filler: mix evenly with mica powder, epoxy resin and curing agent in a ratio of 2:3:1 to make a paste.

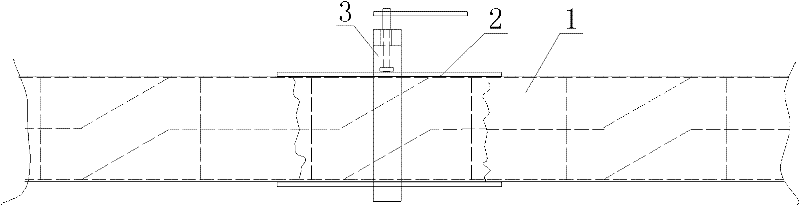

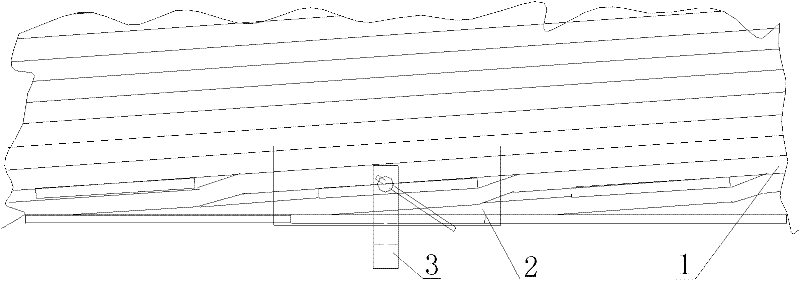

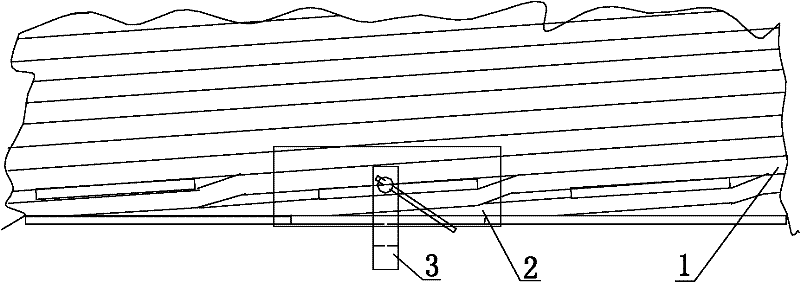

[0019] 2) Place the strip wire rod 1 flat on the work table, clamp the metal splint 2 on both sides of the straight line plane of the wire rod through the cardan 3, and fill the defective parts of the braided flower between the strands of the wire rod Paste filling, make the filling higher than the plane around the bar, and then scrape the filling with bamboo slices.

[0020] 3) Tightly wrap the filling part of the strip wire rod with 2 layers of polytetrafluoroethylene tape, and the reinforcement paste is tightly attached to the defective surface.

[0021] 4) Curing treatment: Place the wound and strengthened strip wire rod 1 at room temperature for natu...

Embodiment 2

[0024] The method for repairing the defective part of the wire-changing braiding pattern between the strands of the motor strip wire rod is characterized in that it includes the following steps:

[0025] 1) Preparation of filler: mix evenly with mica powder, epoxy resin and curing agent in a ratio of 2:3:1 to make a paste.

[0026] 2) Place the strip wire rod 1 flat on the work table, clamp the metal splint 2 on both sides of the straight line plane of the wire rod through the cardan 3, and fill the defective parts of the braided flower between the strands of the wire rod Paste filling, make the filling higher than the plane around the bar, and then scrape the filling with bamboo slices.

[0027] 3) Tightly wrap the filling part of the strip wire rod with 2 layers of polytetrafluoroethylene tape, and the reinforcement paste is tightly attached to the defective surface.

[0028] 4) Curing treatment: In the case of urgent production, it needs to be dried in a drying oven at 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com