Method for guaranteeing electron beam welding coaxiality of large-diameter drum of gas turbine

A gas turbine, large-diameter technology, used in electron beam welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increased production cycle, insufficient precision, low welding coaxiality accuracy, etc., to reduce the scrap rate of parts and stabilize products. Quality, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

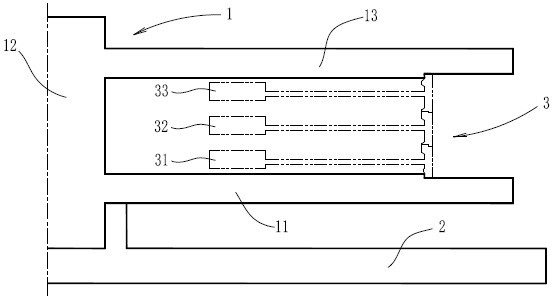

[0020] In this embodiment, the centering of the first-level disc 31 , the second-level disc 32 and the third-level disc 33 of the drum 3 before electron beam welding is taken as an example.

[0021] A method for ensuring the concentricity of electron beam welding of a gas turbine large-diameter drum, comprising the following steps:

[0022] Step 1: Assemble the chassis 11 and shaft 12 of the welding fixture 1 to form a joint, then place the assembled joint on the plane turntable 2, then align the joint on the plane turntable 2, and finally fix the joint On the plane turntable 2;

[0023] Step 2: Place the first-level disk 31 of the drum 3 on the chassis 11 of the welding fixture 1, then align the first-level disk 31 of the drum 3 on the chassis 11 of the welding fixture 1, and finally place the first-level disk 31 of the drum 3 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com