Building stirring method

A technology for construction and mixing buckets, applied in cement mixing devices, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of scraping, inability to realize the residue on the inner wall of the mixing bucket, etc., and achieve increased spray distance and increased water pressure. Large, enhance the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

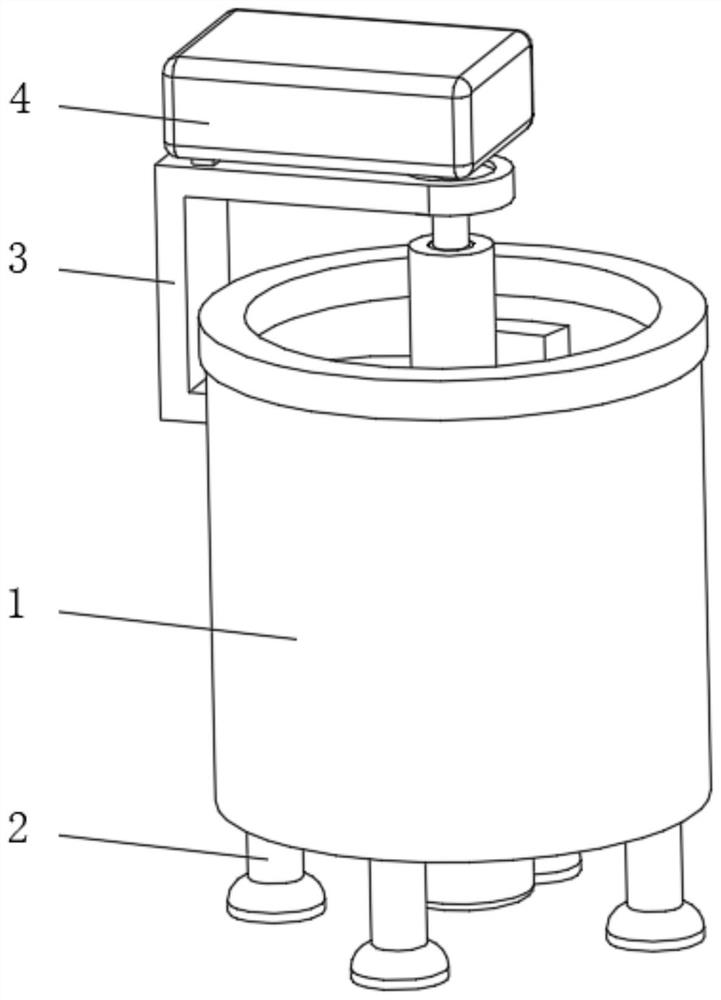

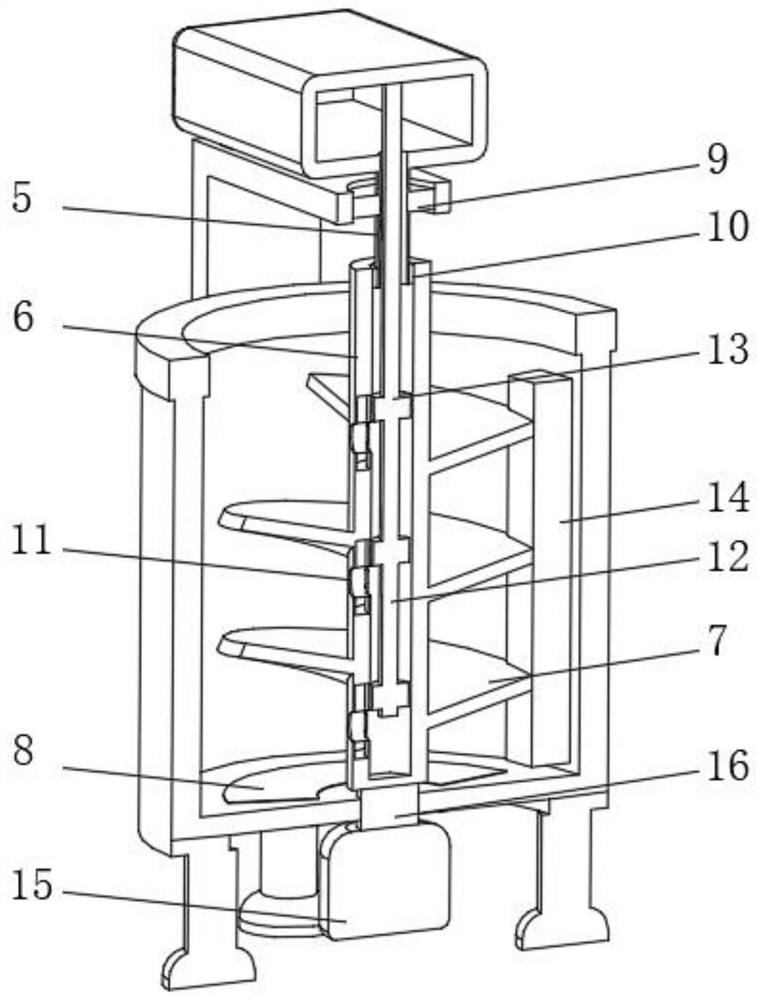

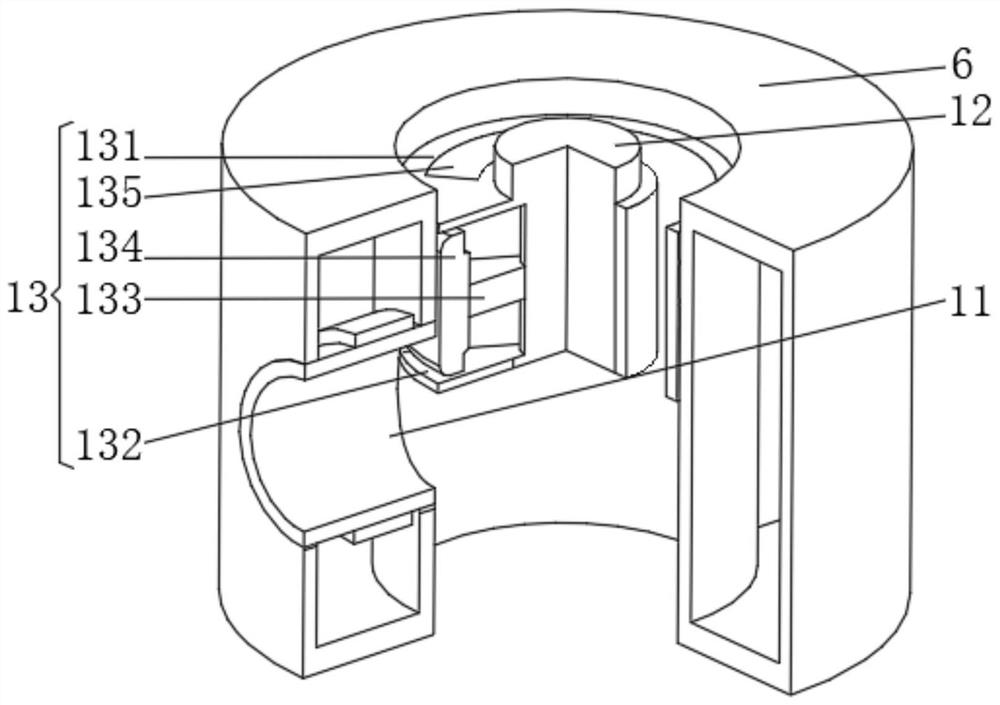

[0028] see Figure 1-5 , the present invention provides a technical solution: a building mixing device, including a mixing bucket 1, a bottom bracket 2 is evenly installed on the bottom of the mixing bucket 1, and a support seat 3 is installed on the outside of the mixing bucket 1 away from the bottom bracket 2, supporting The top of the seat 3 is fixedly connected with the water storage tank 4 through the fixed block, the bottom of the water storage tank 4 is connected with the water outlet pipe 5, and the end of the water outlet pipe 5 away from the water storage tank 4 is connected with the rotating column 6, the rotating column 6 is a metal hollow column, and the rotating column The outer side of 6 is fixedly connected with a spiral stirring plate 7, the bottom of the mixing bucket 1 is provided with a discharge port 8, the outer side of the outlet pipe 5 is provided with a connecting sleeve 9, the outer side of the connecting sleeve 9 is fixedly connected with the support ...

Embodiment 2

[0039] According to above-mentioned a kind of building mixing device, propose a kind of building mixing method now, comprise the following steps:

[0040] S1. Put cement into the mixing bucket, turn on the driving motor to drive the spiral stirring blade through the rotating shaft to stir the cement inside, and through the connection between the outlet pipe and the rotating column, use the driving motor to drive the rotating column to rotate, and the water in the water storage tank will rotate. The column is thrown out from the outlet hole by centrifugal force;

[0041] S2. When the adjusting block completely slides down to the position of the water outlet hole, the elastic brush head in the groove, which was originally squeezed by the inner wall of the rotating column, drives the bristles into the water outlet hole. At this time, the water outlet hole still rotates with the rotation shaft. During this process, The inner wall of the rotating column continuously squeezes the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com