Door clamping mechanism of gasket roll feeding channel of gasket placing machine of wire rod packing machine

The technology of a door mechanism and a push mechanism is applied in the parts, packaging, transportation and packaging of the bundling machinery, which can solve the problems of low operation efficiency and difficulty, and achieve the effect of good use efficiency, low cost and improved insertion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] A clamping door mechanism for the gasket roll feeding channel of the gasket placement machine of the wire rod packing machine,

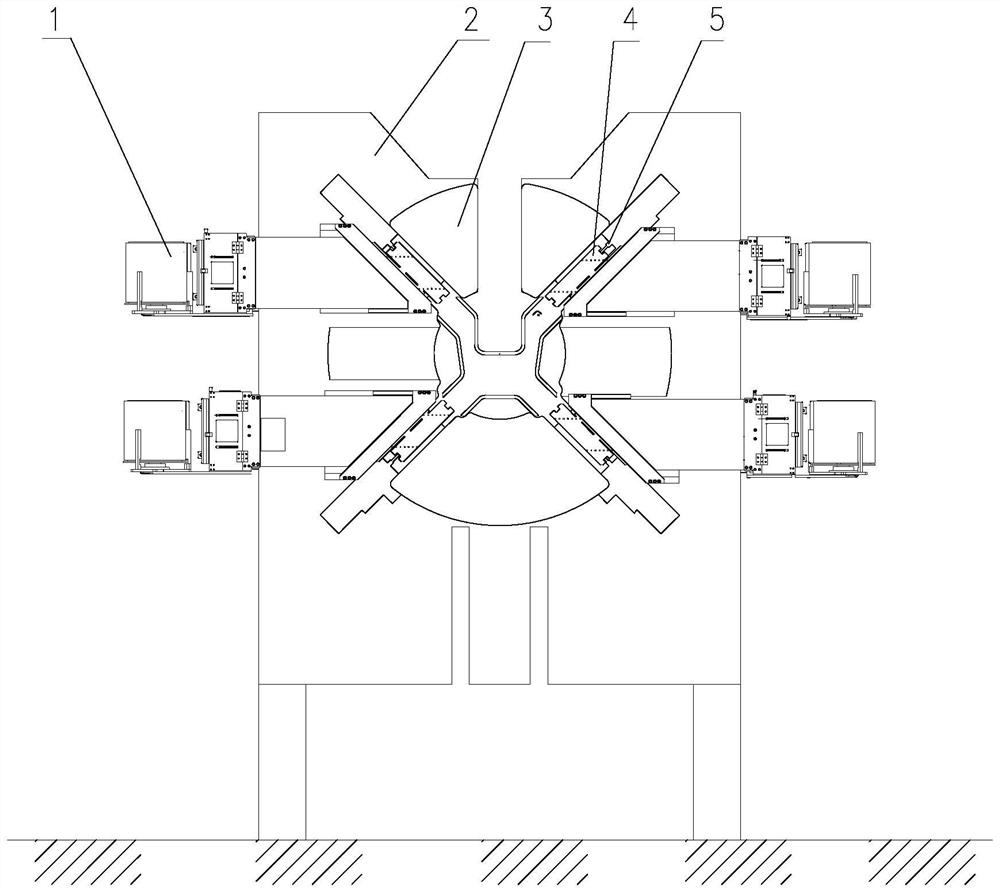

[0046] The gasket placement machine of the wire rod baler is respectively provided with gasket continuous pushing mechanisms at the four opposite corners of the pressure plate 2 to push through the passage of the anti-frustration disc 3 to the slot position of the pressure plate 2 one by one;

[0047] It is characterized by:

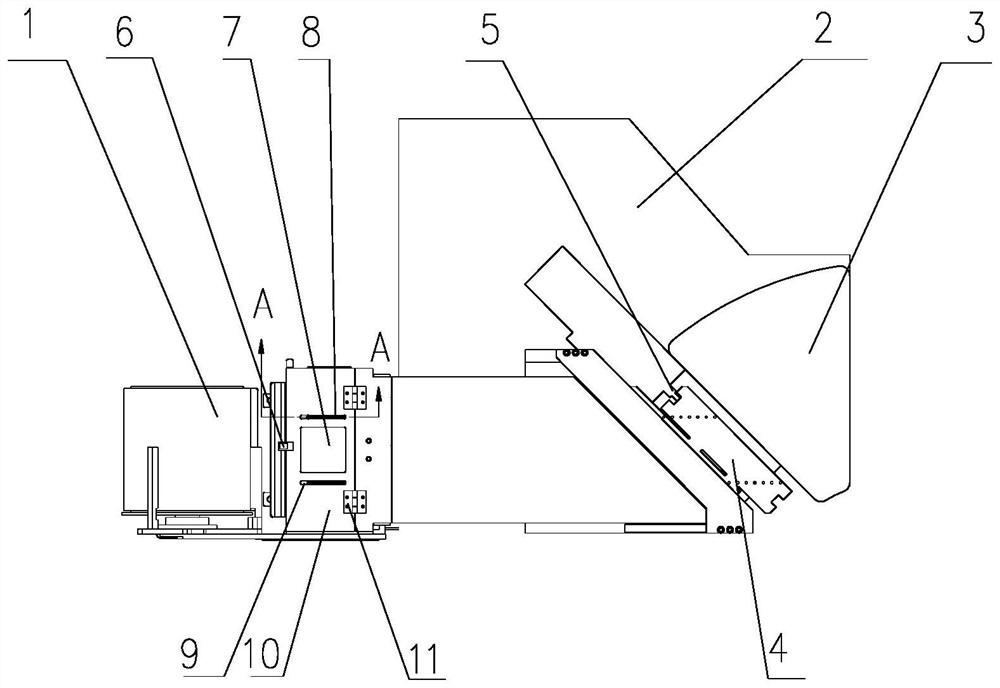

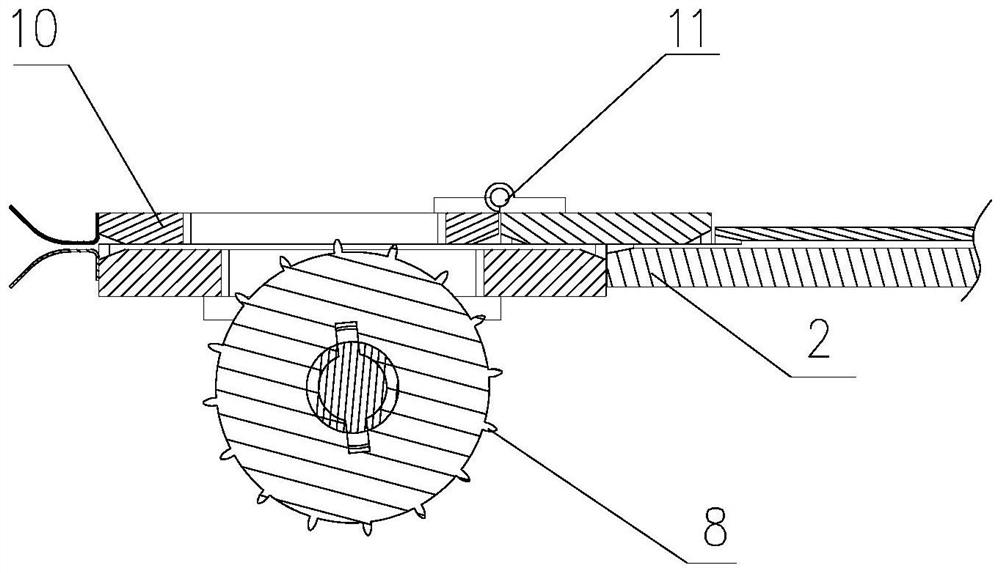

[0048] The gasket continuous pushing mechanism is a conveying roller installed on the back of the pressing plate 2, and there are two circles of protruding teeth 8 for conveying the gasket 4 protruding from the surface of the pressing plate 2;

[0049] The shaft cylinder 1 of the gasket roll is arranged on the outside of the pressure plate 2 in a vertical state;

[0050] A flap 10 with an opening to cover the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com