Well repair device capable of achieving temporary well well sealing and well killing and application method of well repair device

A technology for killing and sealing wells, applied in wellbore/well components, drilling equipment, earth-moving drilling, etc., can solve the problems of large well control risks and environmental pollution, insufficient sealing and anchoring force, casing sealing leakage, etc. Prevention of well control risk and risk of environmental contamination, high sealing pressure, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

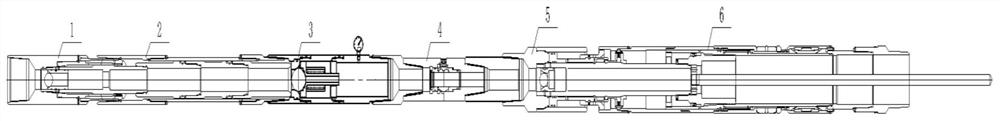

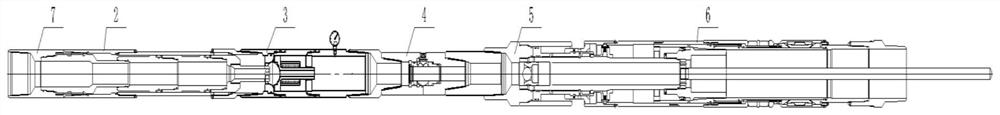

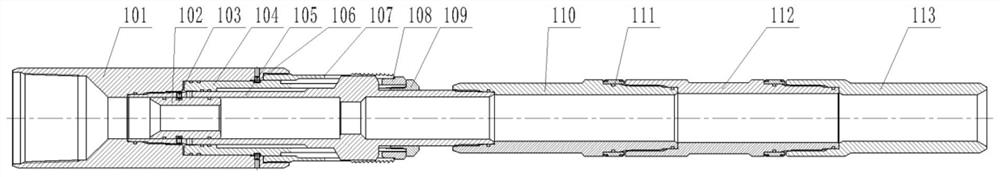

[0040] 1) Workover tubing string for temporary sealing and killing: the connection sequence of the tubing string is from bottom to top, followed by sealing device, sealing tool for sealing device, cock valve, well killing float shoe, tie-back sealing device, etc. Casing sleeve and hydraulically releasable kill tieback.

[0041] 2) Use the drill pipe to send the temporary sealing and killing operation string into the casing, pressurize through the drill pipe, and the pressurized liquid reaches the sealing device through the hydraulically releasable kill tie-back, killing shoe, and plug valve Seating tool. The piston of the sealer setting tool pushes the sealer to move, thereby realizing the swelling seal of the sealer rubber tube and the anchoring of the slips, thereby realizing the sealing and anchoring of the sealer and the casing. At this time, the pressure in the well can be observed through the pressure gauge on the well killing float shoe, and the operation measures to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com