Anti-resonance voltage transformer and manufacturing method thereof

A resonant voltage, transformer technology, applied in the transformer field, can solve problems such as transformer damage, achieve the effect of simple and easy size, and avoid ferromagnetic resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

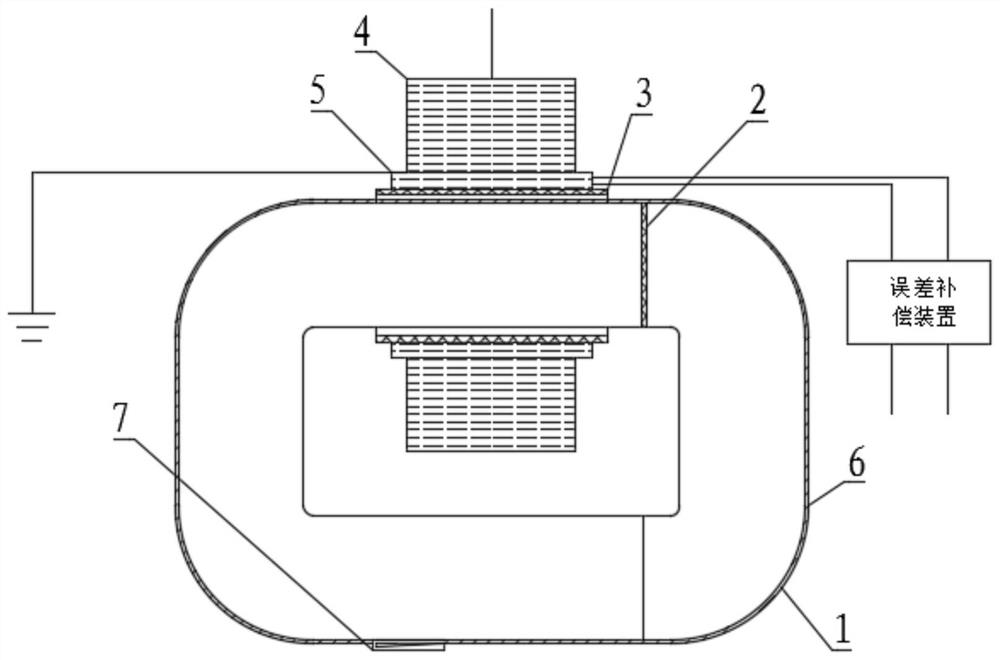

[0039] Please refer to figure 1 , an anti-resonance voltage transformer in this embodiment includes an iron core 1 and a round-shaped insulating frame 3. Specifically, the iron core 1 is a square-shaped iron core 1, and the iron core 1 is cut from a position 30 mm away from one side of the iron core 1. It is divided into two halves, A and B, so that the core 1 can pass through the center of the insulating frame 3 so that the insulating frame 3 can be set on one side of the core 1, wherein the inner diameter of the insulating frame 3 is 1 to 5 mm larger than the outer diameter of the iron core 1, ensuring The iron core 1 fits smoothly and the gap between the iron core 1 and the skeleton is small, and the overall volume of the product is small.

[0040] A secondary winding 5 is wound on the insulating frame 3, and the secondary winding 5 is formed by winding enamelled copper flat wire directly on the insulating frame 3, and three layers of insulating paper are wrapped on the sec...

Embodiment 2

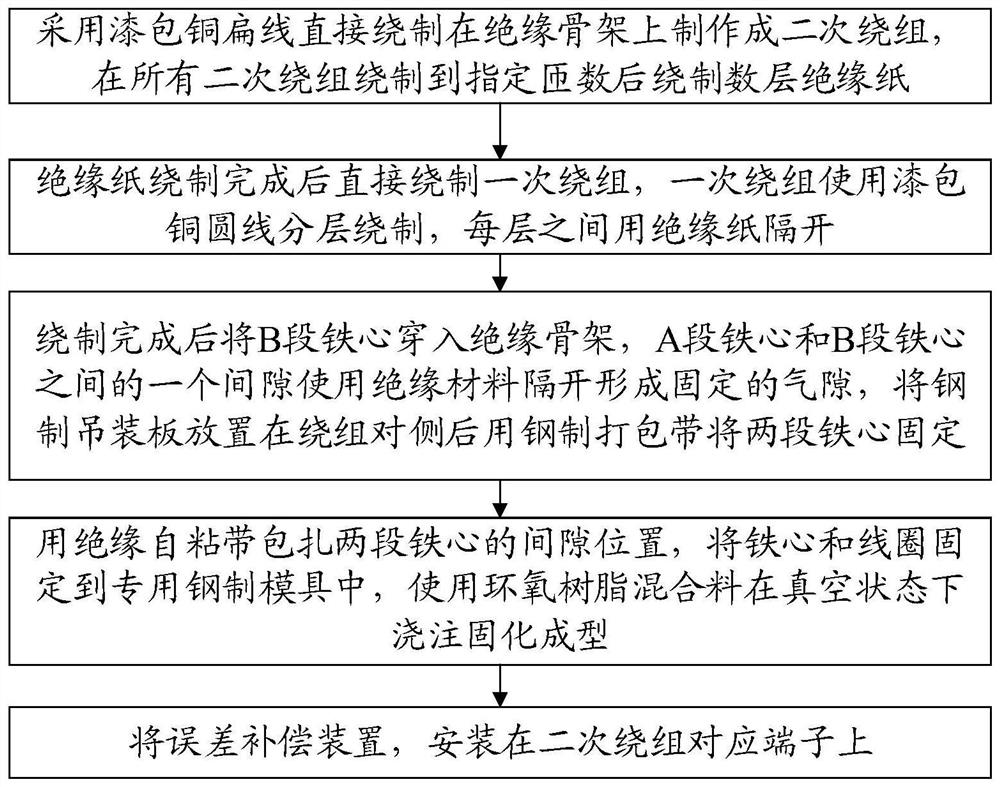

[0046] Please refer to figure 2 , a method of manufacturing an anti-resonance voltage transformer in this embodiment, using enamelled copper flat wire to be directly wound on the insulating frame 3 to form a secondary winding 5, after all the secondary windings 5 are wound to a specified number of turns Wind several layers of insulating paper, preferably 0.07 thick capacitor composite paper wound three layers.

[0047] After the insulating paper is wound, the primary winding 4 is directly wound. The primary winding 4 is wound in layers using enamelled copper round wires, and each layer is separated by insulating paper.

[0048] After the winding is completed, the B-section iron core 1 is penetrated into the insulating skeleton 3. A gap between the A-section iron core 1 and the B-section iron core 1 is separated by an insulating material 2 to form a fixed air gap. The air gap is preferably 1mm. After the hoisting plate 7 is placed on the opposite side of the winding, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com