Composite positive electrode material and preparation method thereof

A positive electrode material and composite layer technology, applied in the field of composite positive electrode material and its preparation, can solve the problems of electrolyte corrosion and structural instability, and achieve the effects of short cycle, low cost, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

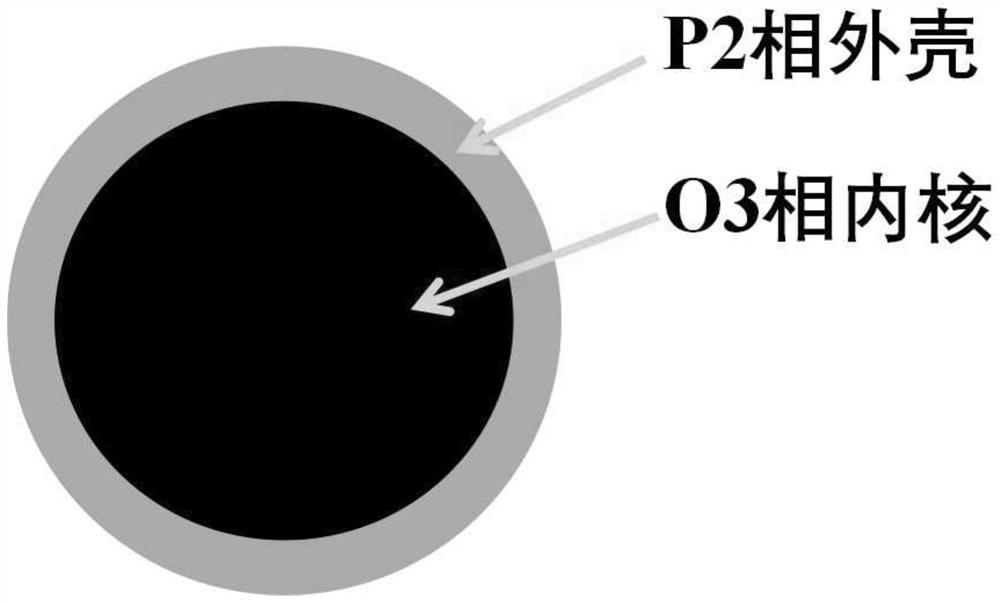

[0043] In this embodiment, the positive electrode material is the Na core of O3 phase. 0.87 Li 0.04 Ni 0.25 Fe0.25 mn 0.5 o 2 , the outer shell is Na in P2 phase 0.67 Li 0.04 Cu 0.10 Fe 0.20 mn 0.70 o 2 The composite layered cathode material was prepared using a co-precipitation method combined with a solid-state reaction. Specific steps are as follows:

[0044] According to the above stoichiometric ratio, the NiSO 4 , FeSO 4 , MnSO 4 Prepare a mixed solution A with a total concentration of 1mol / L, and mix CuSO 4 , FeSO 4 , MnSO 4 Make a mixed solution B with a total concentration of 1mol / L, and configure the complexing agent NH 3 ·H 2 O solution C and precipitant Na 2 CO 3 Solution C; inject solution A, solution C and solution D into the reaction vessel at the same time, and carry out co-precipitation reaction at 50 ° C; after the reaction, inject solution B, solution C and solution D into the reaction vessel at the same time. Carry out co-precipitation re...

Embodiment 2

[0056] In this embodiment, the positive electrode material is the Na core of O3 phase. 0.84 Li 0.05 Ni 0.30 Fe 0.25 mn 0.45 o 2 , the outer shell is Na in P2 phase 0.65 Li 0.05 Mg 0.06 Cu 0.10 Fe 0.16 mn 0.68 o 2 The composite layered cathode material was prepared using a co-precipitation method combined with a solid-state reaction. Specific steps are as follows:

[0057] According to the above stoichiometric ratio, the NiSO 4 , FeSO 4 , MnSO 4 Prepare a mixed solution A with a total concentration of 1mol / L, and mix CuSO 4、 MgSO 4 , FeSO 4 , MnSO 4 Make a mixed solution B with a total concentration of 1mol / L, and configure the complexing agent NH 3 ·H 2 O solution C and precipitant Na 2 CO 3 Solution C; inject solution A, solution C and solution D into the reaction vessel at the same time, and carry out co-precipitation reaction at 50 ° C; after the reaction, inject solution B, solution C and solution D into the reaction vessel at the same time. Carry ou...

Embodiment 3

[0059] In this embodiment, the positive electrode material is the Na core of O3 phase. 0.87 Li 0.03 Ni 0.30 Fe 0.30 mn 0.40 o 2 , the outer shell is Na in P2 phase 0.66 Li 0.03 Ni 0.10 Cu 0.08 Fe 0.10 mn 0.72 o 2 The composite layered cathode material was prepared using a co-precipitation method combined with a solid-state reaction. Specific steps are as follows:

[0060] According to the above stoichiometric ratio, the NiSO 4 , FeSO 4 , MnSO 4 Make a mixed solution A with a total concentration of 1mol / L, NiSO 4 、CuSO 4 , FeSO 4 , MnSO 4 Make a mixed solution B with a total concentration of 1mol / L, and configure the complexing agent NH 3 ·H 2 O solution C and precipitant Na 2 CO 3 Solution C; inject solution A, solution C and solution D into the reaction vessel at the same time, and carry out co-precipitation reaction at 50 ° C; after the reaction, inject solution B, solution C and solution D into the reaction vessel at the same time. Carry out co-precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com