Method for reducing alkali consumption in aluminum removal of battery positive electrode waste

A technology for battery positive electrode and positive electrode material, which is applied in the field of reducing alkali consumption and removing aluminum from battery positive electrode waste, can solve the problems affecting the electrochemical stability of the product, rate performance, low aluminum removal efficiency, and aluminum performance influence, etc., and achieve fast and efficient. Aluminium removal, avoid influence, improve the effect of aluminum removal kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

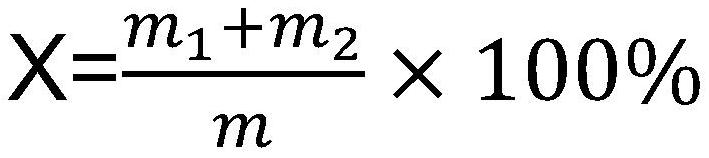

Method used

Image

Examples

Embodiment 1

[0026] According to the liquid-solid ratio of 6:1, 100g of lithium iron phosphate positive electrode waste (particle size is 31 μm, aluminum content is 3.4%) and 1.5wt% NaOH solution are placed in the stirring mill, the reaction time is 2h, and the stirring mill speed is 1500r / min, during which 1g of ascorbic acid was added every 20min, a total of 3g, after the reaction, the ore slurry was filtered to obtain filter residue and filtrate; the filter residue was subjected to the second grinding and leaching, and 5wt% NaOH solution was added according to the liquid-solid ratio of 4:1, and the reaction time was 1h. The rotational speed of the mill was 2000r / min, during which 0.5g of ascorbic acid was added every 30min, and the aluminum leaching rate was 96%.

Embodiment 2

[0028] Compared with Example 1, the ascorbic acid is changed to use tea polyphenols.

[0029] According to the liquid-solid ratio of 6:1, 100g of lithium iron phosphate positive electrode waste (particle size is 31 μm, aluminum content is 3.4%) and 1.5wt% NaOH solution are placed in the stirring mill, the reaction time is 2h, and the stirring mill speed is 1500r / Min, during which 1g of tea polyphenols was added every 20min, 3g in total, after the reaction, the slurry was filtered to obtain the filter residue and filtrate; the filter residue was subjected to the second grinding and leaching, and 5wt% NaOH solution was added according to the liquid-solid ratio of 4:1, and the reaction time was 1h , the rotating speed of the mixing mill is 2000r / min, during which 0.5g ascorbic acid is added every 30min, and the aluminum dipping rate is 95%.

Embodiment 3

[0031] Compared with Example 1, the NaOH concentration of the first aluminum immersion was reduced to 1 wt%.

[0032] According to the liquid-solid ratio of 6:1, 100g of lithium iron phosphate positive electrode waste (particle size is 31 μm, aluminum content is 3.4%) and 1wt% NaOH solution are placed in the stirring mill, the reaction time is 2h, and the stirring mill speed is 1500r / min , add 1g of ascorbic acid every 20min during this period, 3g in total, after the reaction, the ore slurry is filtered to obtain filter residue and filtrate; the filter residue is subjected to grinding and leaching for the second time, and 5wt% NaOH solution is added according to the liquid-solid ratio of 4:1, and the reaction time is 1h. The rotating speed of the machine is 2000r / min, during which 0.5g ascorbic acid is added every 30min, and the aluminum dipping rate is 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com