Automatic pressing hydraulic machine for commutator

A technology of automatic pressing and hydraulic press, which is applied in the direction of commutator manufacturing, etc., can solve the problems of high work intensity, high mobility of personnel, and difficult breakthrough in processing technology, and achieve the effect of increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

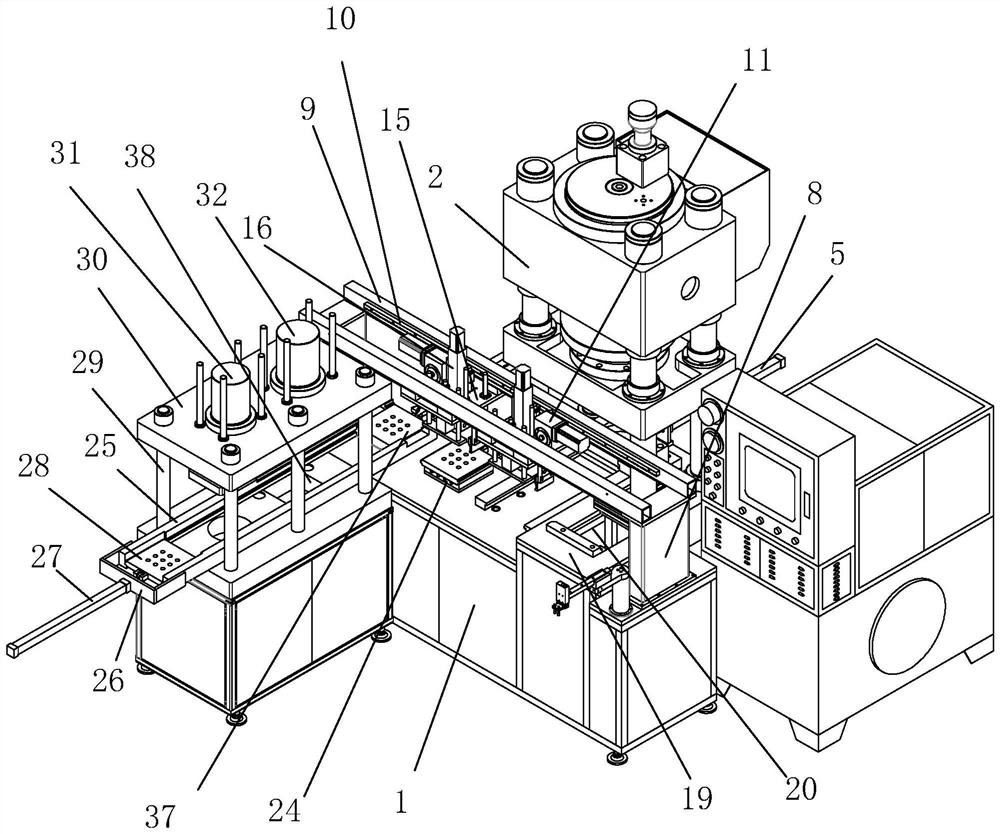

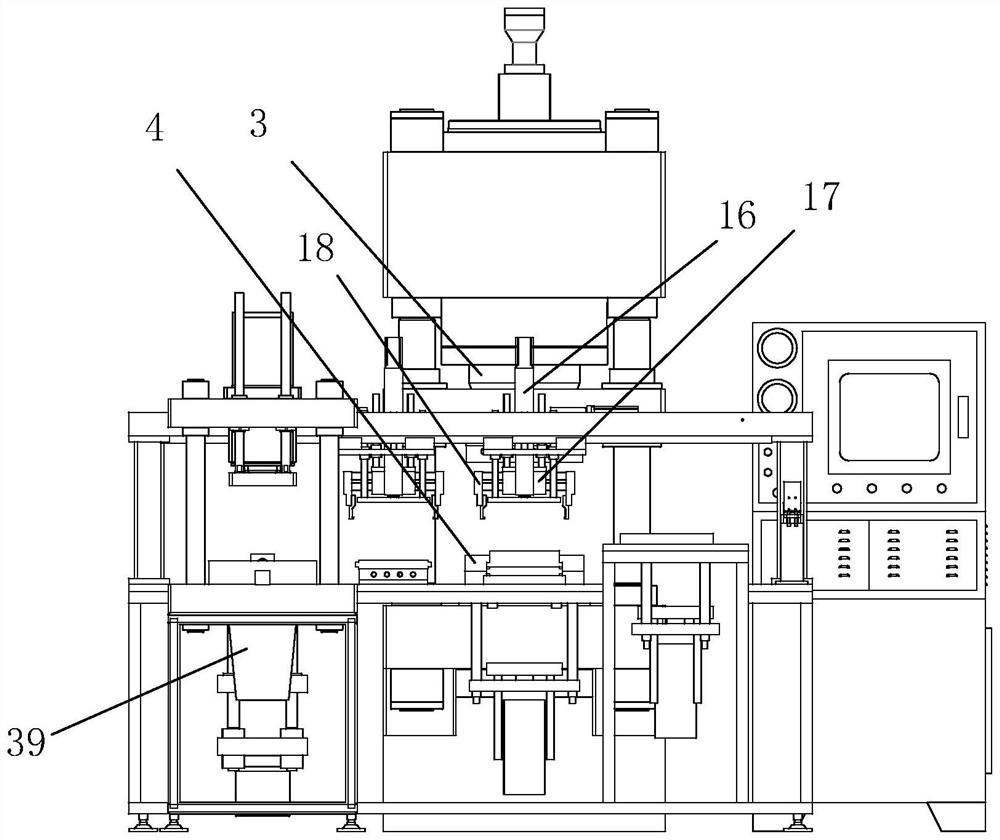

[0032] The present invention will be further described with reference to the accompanying drawings.

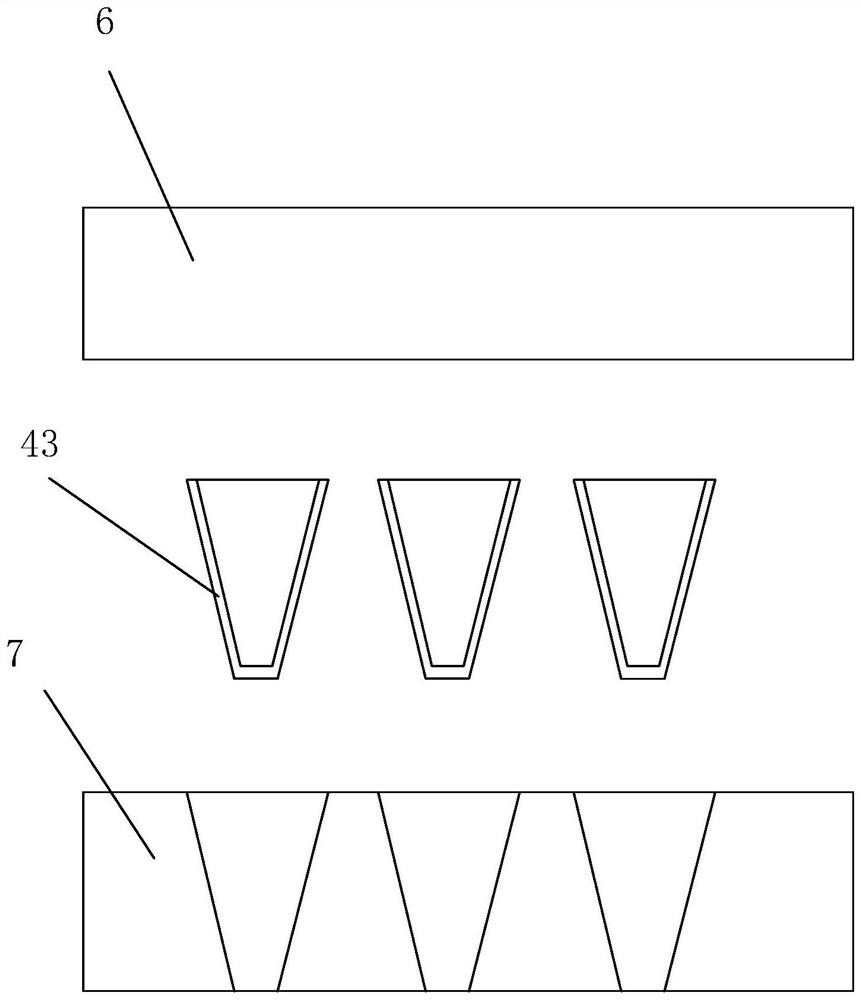

[0033] A commutator automatic pressing hydraulic press, such as Figure 1-Figure 9As shown, it includes a workbench 1, one side of the workbench 1 is provided with a hydraulic press 2 above the workbench 1, the hydraulic press 2 is connected with a hydraulic plate 3, and the lower part of the hydraulic plate 3 is provided with a bearing plate 4, The workbench 1 is provided with a driving cylinder 5 fixedly connected to the load plate 4, and a mold is placed above the load plate 4, and the mold includes an upper mold 6 and a lower mold 7 that can cover each other, and the workbench 1 is provided with a clamping piece. When the driving cylinder 5 drives the carrying plate 4 to move to the bottom of the clamping piece, the clamping piece can clamp the mold on the carrying plate 4 and move. One side of the workbench 1 is set There is a material picking area, and the other side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com