High-recovery-rate residual film recovery device suitable for cotton

A technology with high recovery rate and residual film recovery, which is applied in application, collectors, plant protection covers, etc., can solve the problems of residual film easily entangled with machinery, damage to soil physical properties, incompleteness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

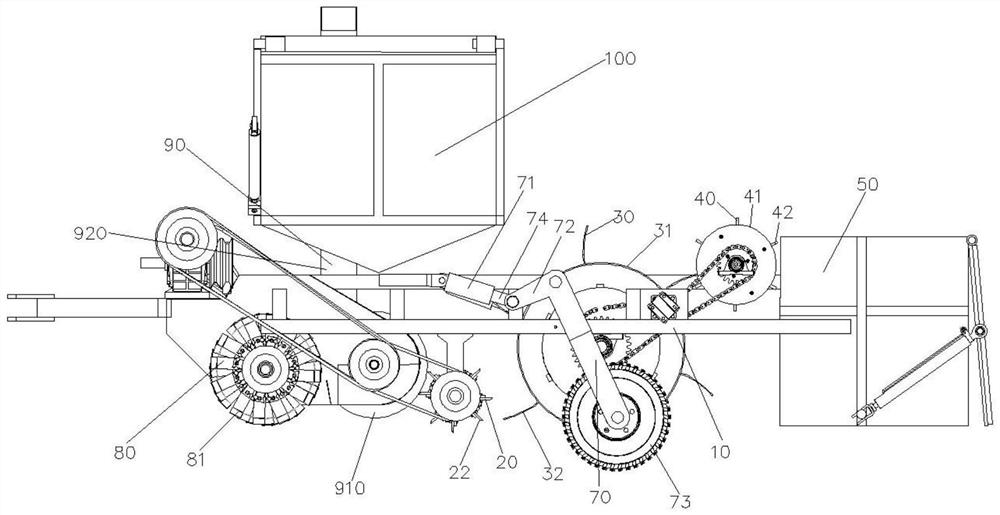

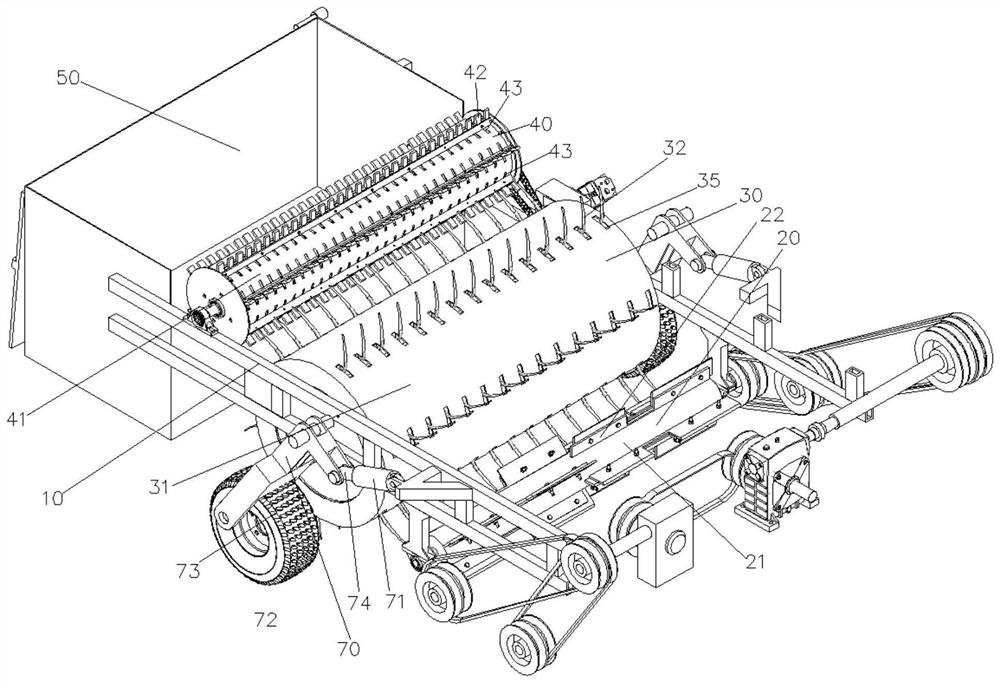

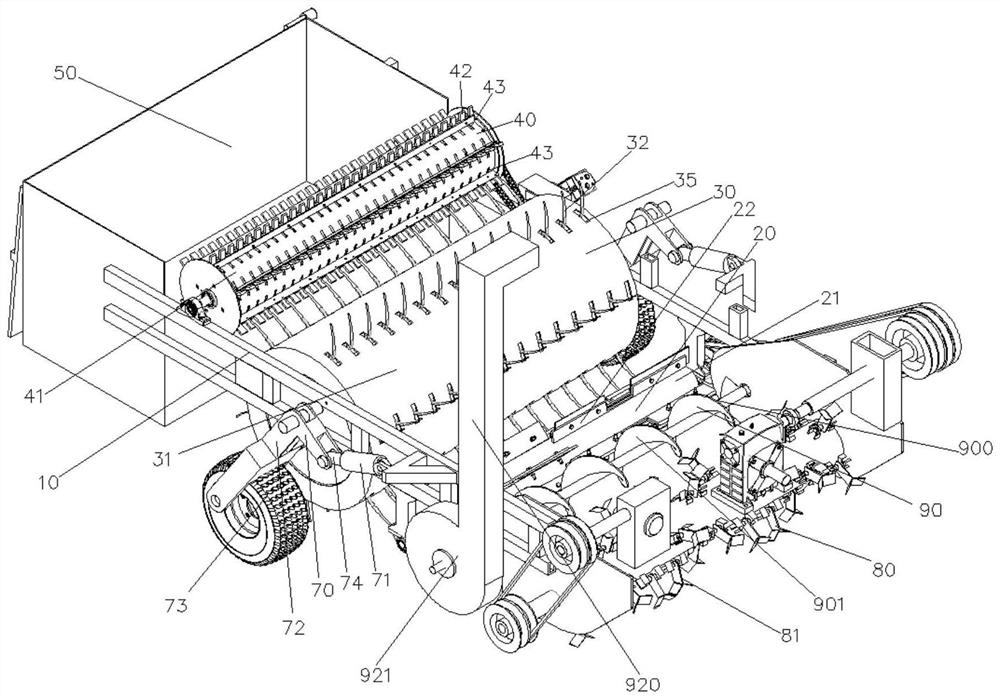

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

[0024] Such as Figure 1-Figure 7 As shown, this high recovery rate residual film recovery device suitable for cotton includes a frame 10, a film lifting mechanism 20, a film picking mechanism 30, a film stripping mechanism 40, a recovery box 50 and transmission parts, wherein the film lifting mechanism 20 passes through the transmission Components are rotatably fixed below the frame 10, the film picking mechanism 30 is rotatably arranged behind the film lifting mechanism 20 through the transmission parts, and the stripping mechanism 40 is rotatably arranged behind the film picking mechanism 30 through the transmission parts, and the recovery box 50 Be arranged at the film stripping mechanism 40 rears, wherein the film stripping mechanism 20 includes the stripping film roller 21 and the stripping shovel 22 arranged on the stripping roller 21, the stripping strip 22 is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com