Flexible inner wall floating grinding table

A grinding table and flexible technology, applied in the directions of grinding machines, grinding workpiece supports, grinding machine parts, etc., can solve the problems that the dust suction port is easy to block the line of sight, the labor intensity of workers is high, and the adsorption effect is not good, and it can achieve a good blocking effect. Dust effect, realize automatic processing, good effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

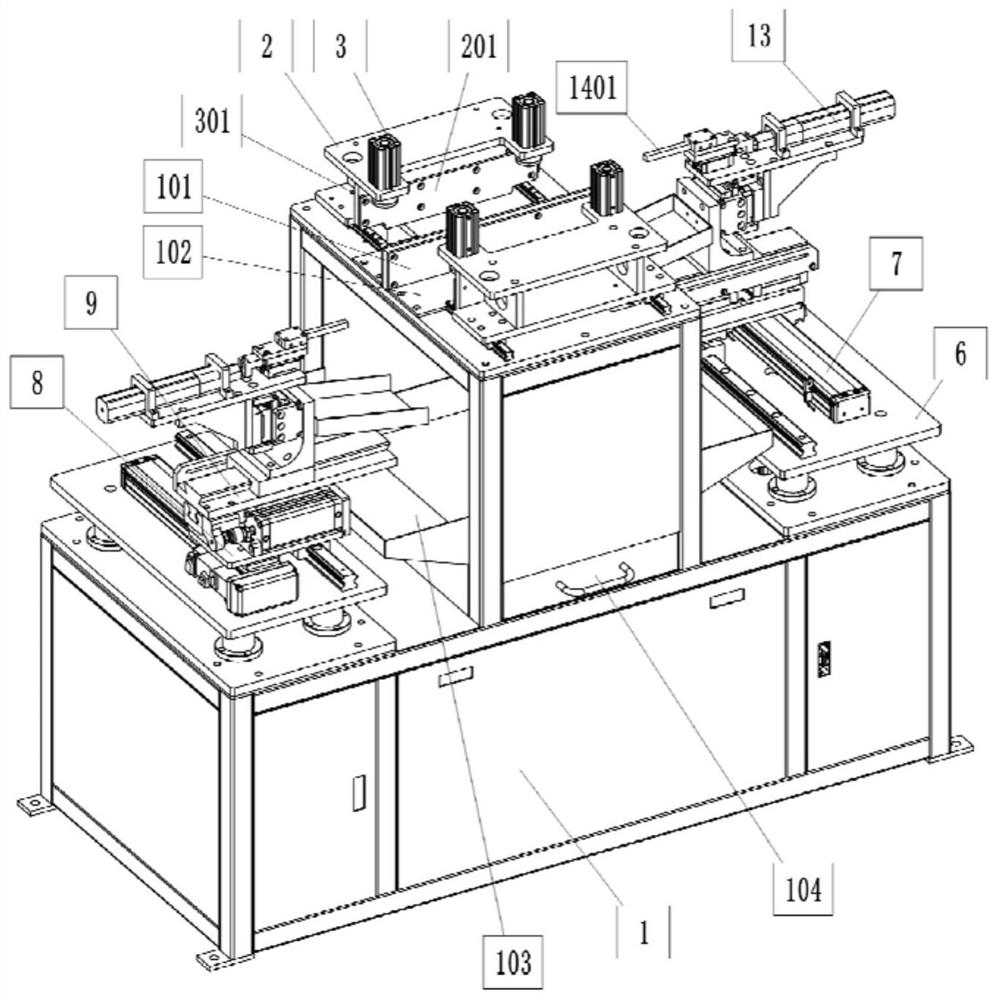

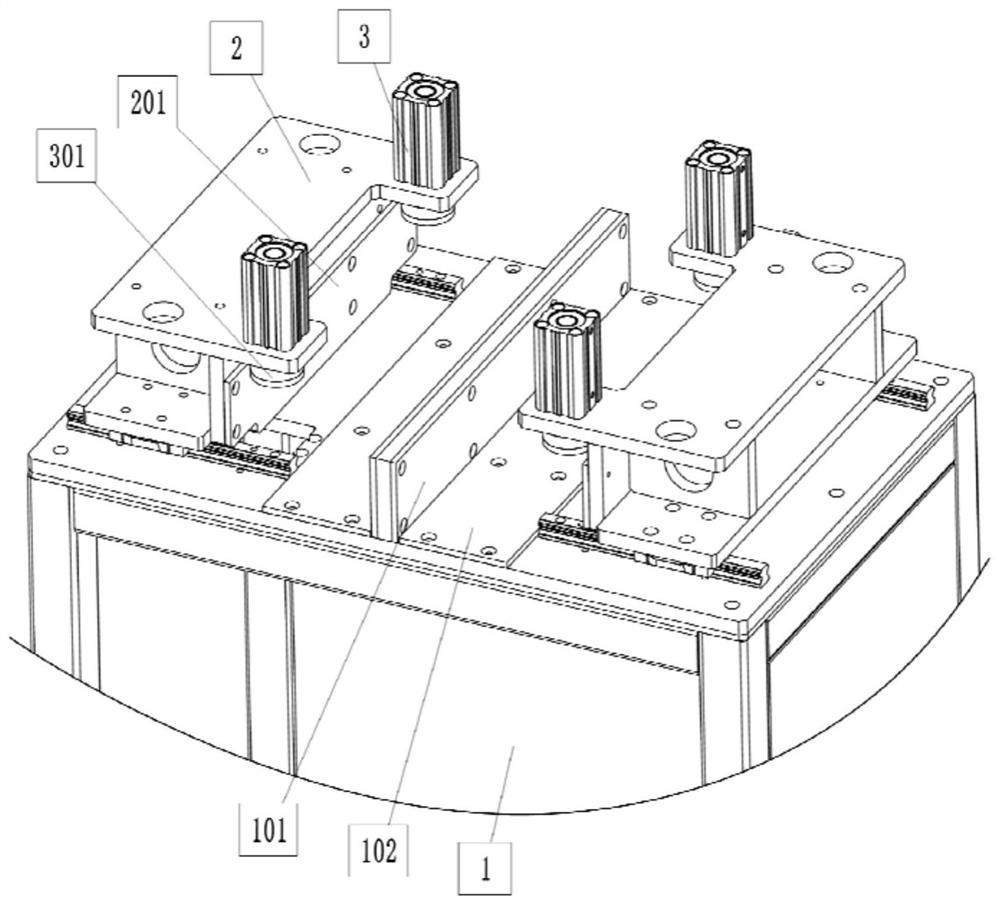

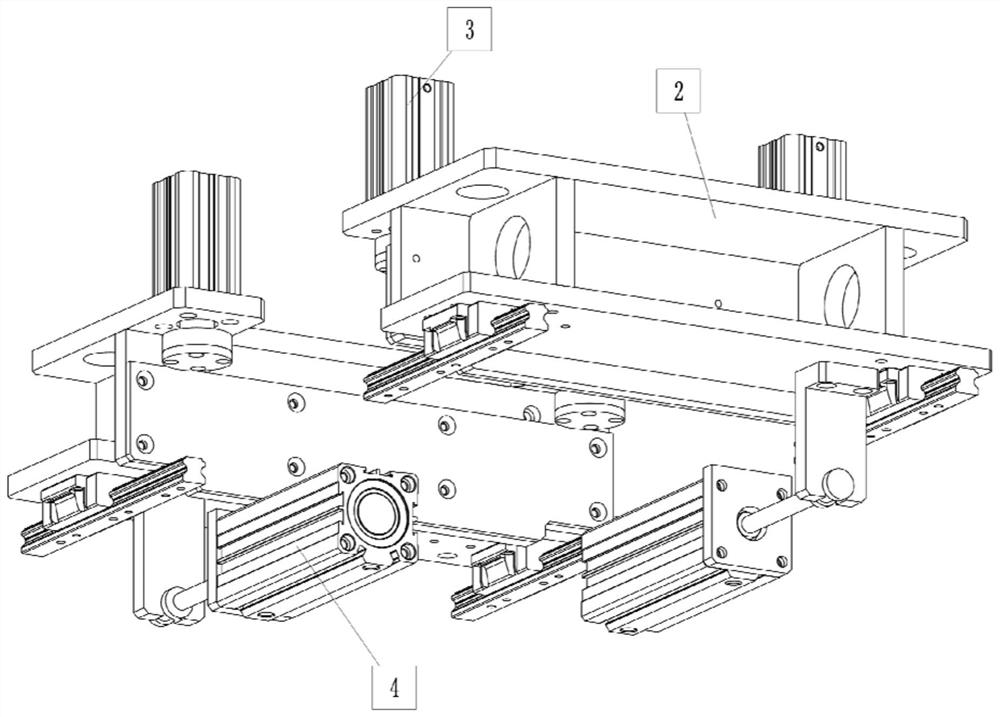

[0065] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a flexible inner wall floating grinding table, including a grinding table bracket 1;

[0066] There are two sets of workpiece fixing components. The two sets of workpiece fixing components are symmetrically arranged on the top of the grinding table bracket 1. The workpiece fixing components are composed of the workpiece pushing part 2, the workpiece pushing driving part 4, the workpiece positioning mechanism, The workpiece pressing component is formed; further, the workpiece positioning mechanism also includes: the workpiece positioning vertical surface 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com