Method for producing semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device production, can solve problems such as incomplete electrical connection and conductive disconnection of lower and upper interconnects 302 and 307

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

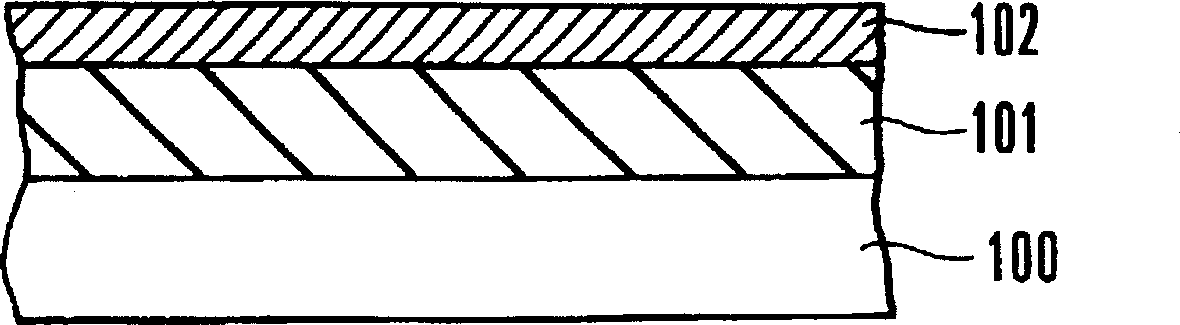

[0024] First, if Figure 1A As shown, a predetermined element (not shown), a wiring layer (not shown) to be distributed on the element, and the like are formed on a semiconductor substrate 100, and an interlayer insulating film 101 is formed to cover the semiconductor substrate 100. surface. Then, lower interconnect 102 made of aluminum is formed on interlayer insulating film 101 .

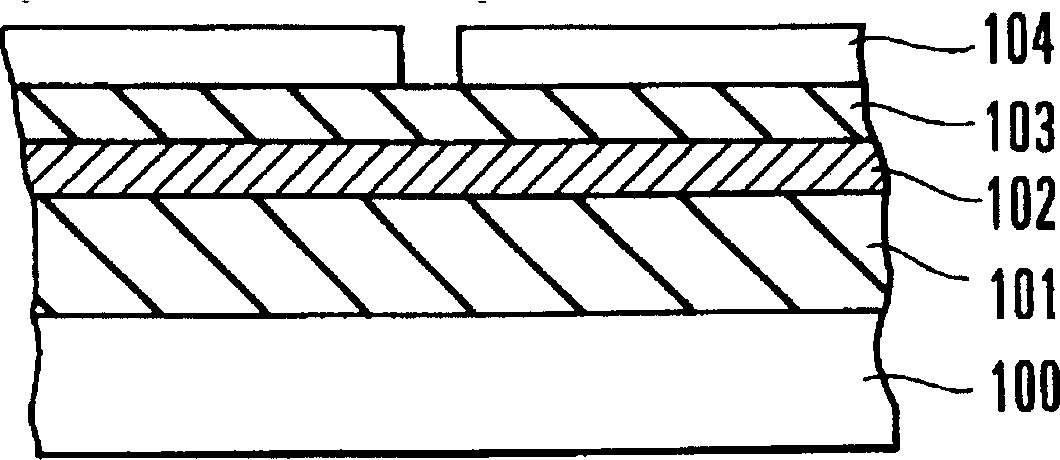

[0025] Such as Figure 1B As shown, an interlayer insulating film 103 is formed on an interlayer insulating film 101 including a lower interconnection 102, and a protective pattern 104 having an opening is formed on the interlayer insulating film 103 on the lower interconnection 102 by using a known photolithography technique.

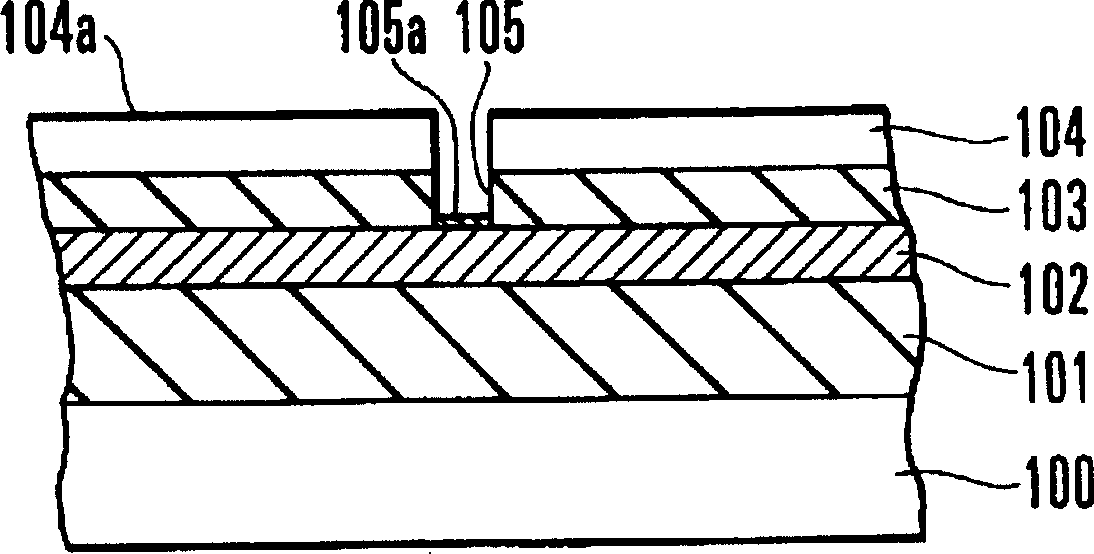

[0026] Such as Figure 1C As shown, by using the resist pattern 104 as a mask, the interlayer insulating film 103 is selectively etched by dry etching (reactive ion etching) using a fluorine-containing gas, thereby forming a via hole 105 . More specifically, fluorinate...

no. 2 example

[0035]The case where a conductive antireflection film is formed on a metal wiring layer (for example, an aluminum layer) will be described below. When the degree of microfabricated patterns increases, when forming fine interconnection patterns by photolithography, anti-reflection patterns are used to suppress light reflection of the bottom layer.

[0036] First, if Figure 2A As shown, a predetermined element (not shown), a wiring layer (not shown) to be distributed on the element, and the like are formed on a semiconductor substrate 200, and an interlayer insulating film 201 is formed to cover the semiconductor substrate 200. surface. Then, lower interconnection 202 made of aluminum is formed on interlayer insulating film 201 . A conductive anti-reflection coating 202 a is formed on the lower interconnect 202 . Figure 2A A cross-sectional view of the lower interconnection 202 in the width direction is shown.

[0037] Such as Figure 2B As shown, an interlayer insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com