Steam turbine generator unit waste heat heating control method and steam turbine generator unit

A technology of a steam turbine generator set and a control method, which is applied in the control of superheat temperature, hot water central heating system, heating method, etc., can solve problems such as the reduction of power generation efficiency, and achieve the reduction of failure rate, production cost, and steam exhaust. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

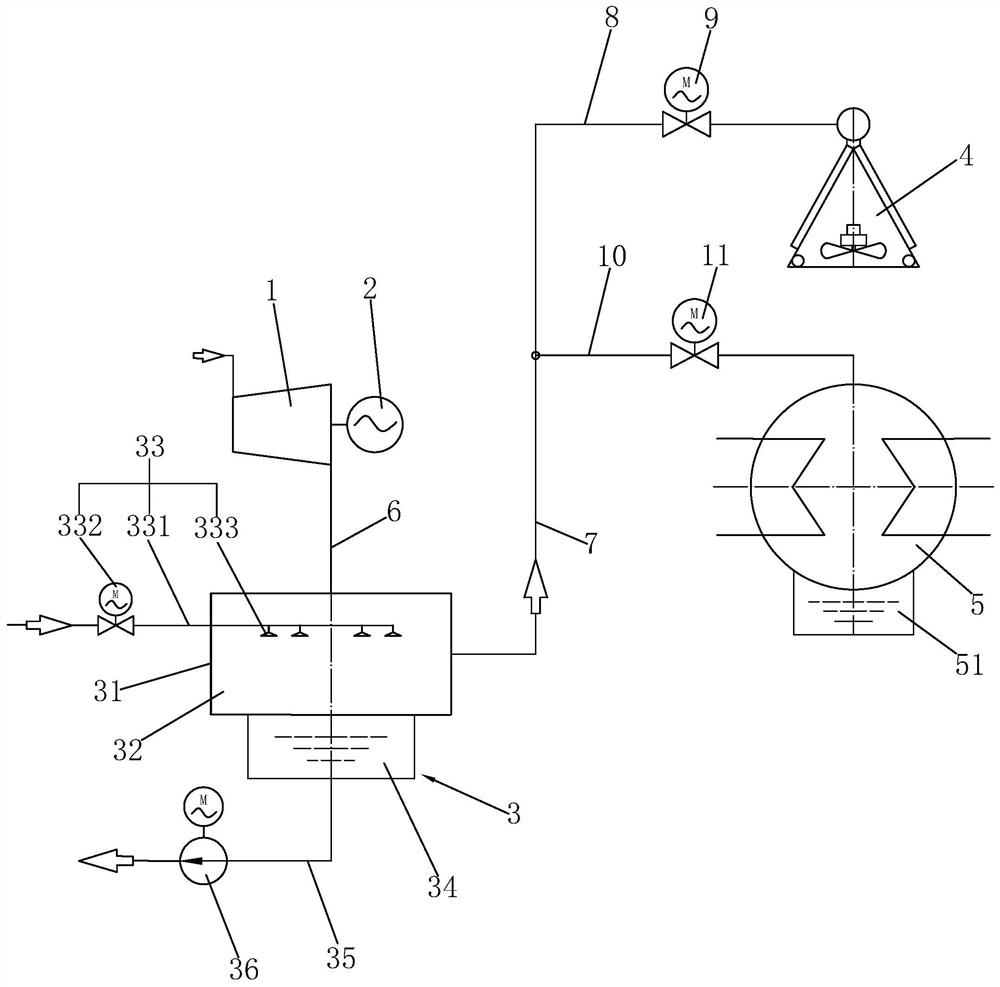

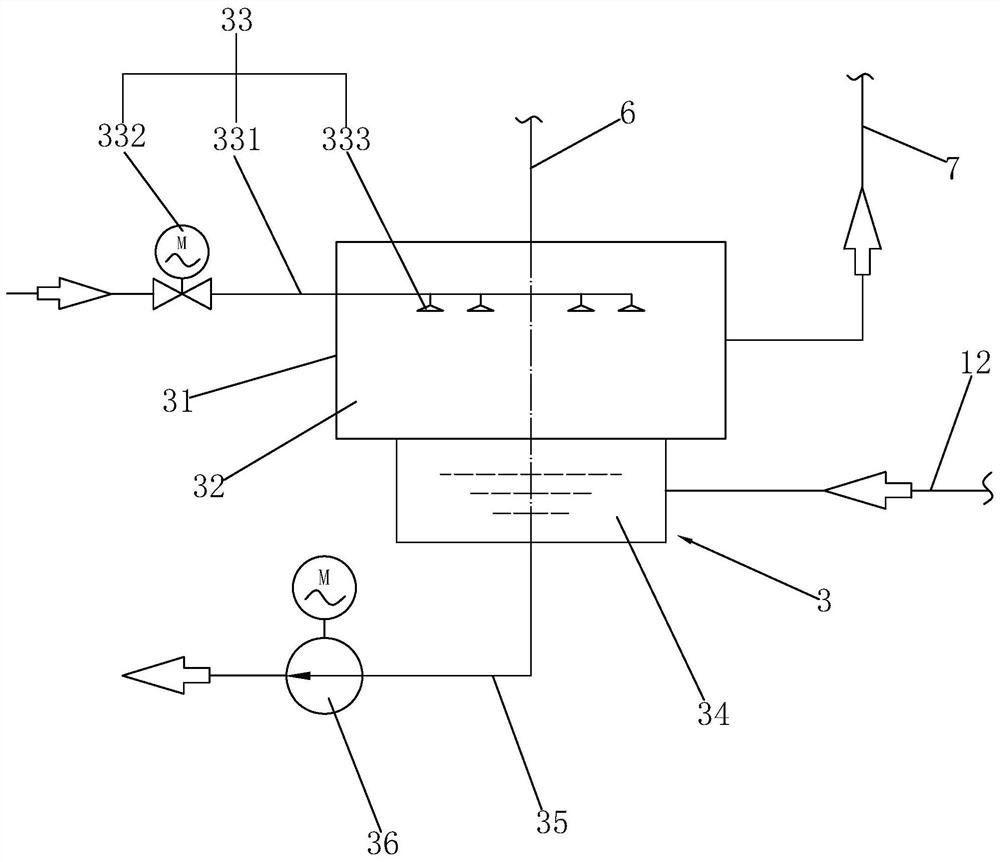

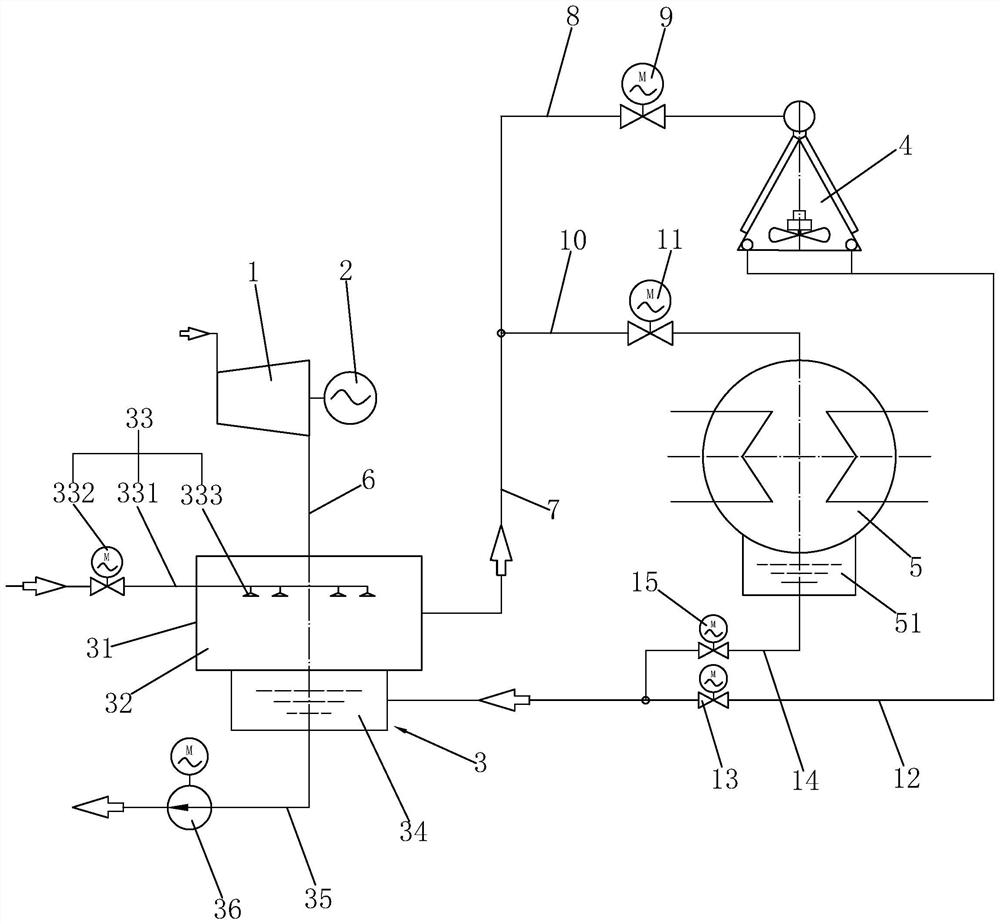

[0044] Such as figure 1 As shown, the present invention proposes a steam turbine generator set, including a steam turbine 1 and a generator 2. The steam turbine 1 and the generator 2 are coaxially connected through a coupling. When working, the steam generated by the boiler enters the steam turbine 1 and expands to perform work. , so that the blades rotate to drive the generator 2 to generate electricity, and the steam releasing thermal potential energy will be discharged from the exhaust port of the steam turbine 1, and the discharged steam is called exhaust steam.

[0045]The steam turbine generator set also includes a steam exhaust device 3 for cooling exhaust steam, an air cooler 4 and a surface c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap