Gas generator set rotor shaft voltage on-line monitoring device

A monitoring device and generator set technology, which is applied to gas turbine devices, jet propulsion devices, safety devices, etc., can solve the problems of increasing the risk of damage to the main equipment of the generator, not being able to obtain the shaft voltage in real time, and not designing a monitoring system, etc. The effect of damage risk, improving safety and reliability, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

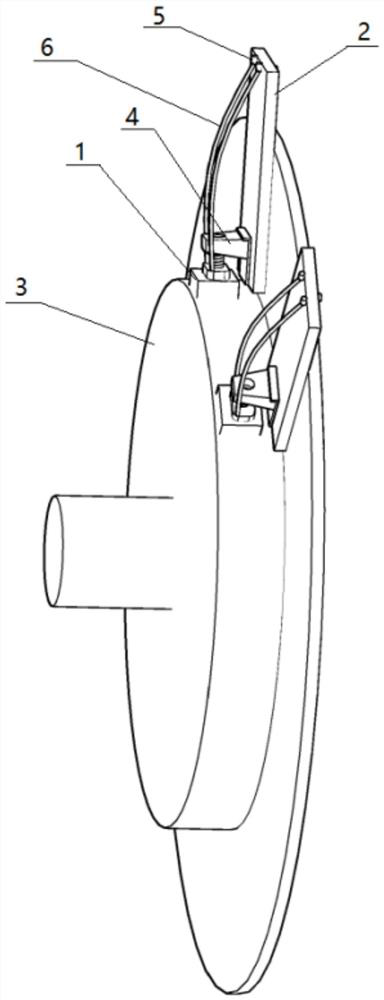

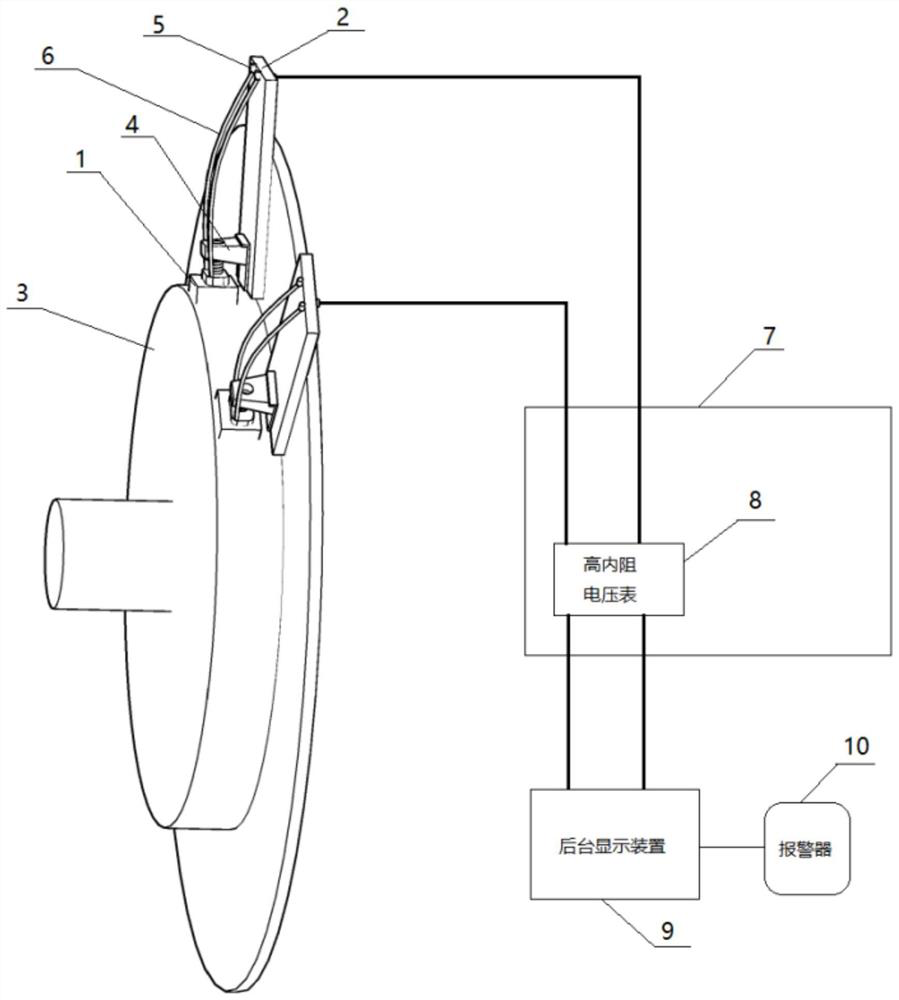

[0024] A gas generator set rotor shaft voltage on-line monitoring device, such as Figure 1-2 As shown, it includes the monitoring device body and the unit control cabinet 7. There are two monitoring device bodies. The monitoring device body includes a conductive carbon brush 1 and a brush bracket 2. The brush bracket 2 adopts an epoxy resin plate with a thickness of 8mm, and the conductive carbon brush 1 is set close to the rotor shaft 3, the brush holder 2 is provided with a brush holder 4, the specification of the brush holder 4 is 25*32*100mm, the brush holder 4 is provided with a bolt hole, and an insulating ring is provided in the bolt hole Oxygen resin paint layer, conductive carbon brush 1 is connected with brush holder 4 by bolts, conductive carbon brush 1 can move freely up and down in brush holder 4 without jamming, and the contact surface coincides with the radian of rotor shaft 3 by more than 75%, conductive carbon brush 1 The model is NCC634, suitable for high-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com