Flexible metal armored field operation optical cable

A field optical cable and flexible metal technology, applied in the field of field optical cable, can solve problems such as difficult wiring and difficult bending of optical cable, and achieve the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

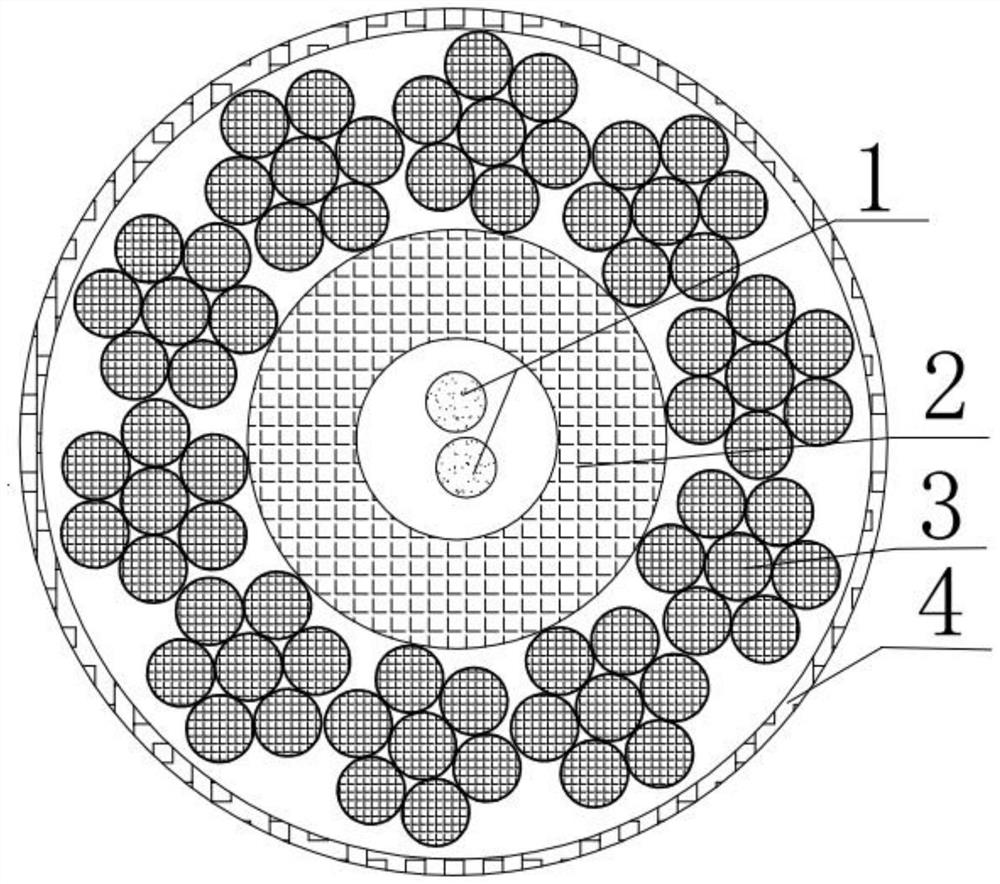

[0023] see figure 1 , is a cross-sectional view of an embodiment of the flexible metal-armored field optical cable of the present invention, the flexible metal-armored field optical cable includes a cable core layer 1, a spiral armored tube 2, a steel wire strand armor layer 3 and an outer sheath 4, wherein the cable The core layer 1 is provided with a single optical fiber or multiple optical fibers and some fillers, the spiral armored tube 2 is wrapped on the outside of the cable core layer 1, the steel wire strand armor layer 3 is wrapped on the outside of the spiral armored tube 2, and the outer sheath 4 wrapped in the outside of the steel wire rope strand armor layer 3. The thickness of the spiral armored tube is 0.15mm-0.3mm, the spiral gap is 0.05mm-0.15mm, the armor layer of the steel wire rope strands is a plurality of strands twisted with each other, and the stranding pitch between the strands of steel wire strands is 30mm -70mm. In this embodiment, the steel wire st...

Embodiment 2

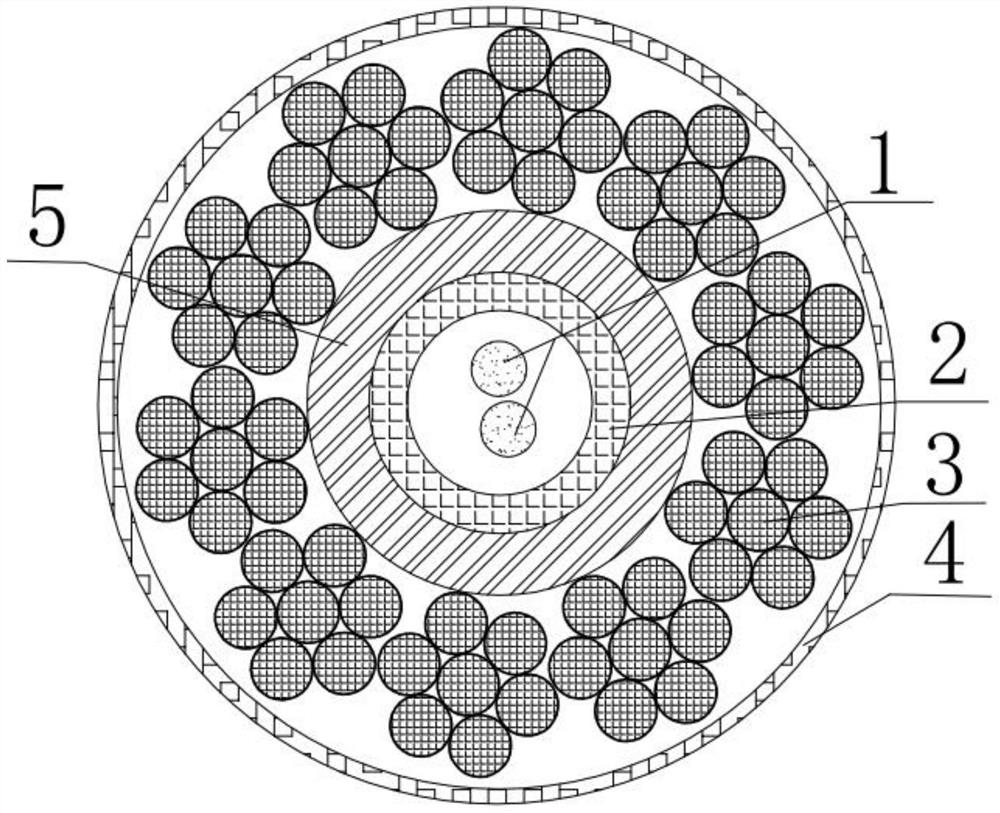

[0025] see figure 2 , is a sectional view of Embodiment 2 of the flexible metal-armored field optical cable of the present invention. The main difference between this embodiment and Embodiment 1 is that a layer is added between the spiral armored tube 2 and the steel wire rope strand armor layer 3 The flexible sheath layer 5 is used to increase the overall flexibility of the field optical cable. The wall thickness of the flexible sheath layer 5 is 0.4mm-1.5mm. The flexible sheath layer 5 can be made of polyethylene, polyurethane, silicone rubber or fluoroplastics. made of any material.

[0026] The manufacturing method of the invented flexible metal armored field optical cable is as follows: first, the stainless steel strip is made by pressing wire, and the stainless steel strip with a wall thickness of 0.2mm is formed by pressing the wire with 0.5mm stainless steel wire, and then single or multiple optical fibers are laid out The wire is put into the digital control tube ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com