Coal mining machine traction system and control method thereof

A traction system and traction control technology, which is applied in the direction of multiple motor speed adjustment, output power conversion device, electrical components, etc., can solve the problem of high design cost and accessories cost, inconvenient installation and debugging, and the volume of frequency converter and traction asynchronous motor Large and other problems, to avoid wear or other failures, simplify the structure, improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

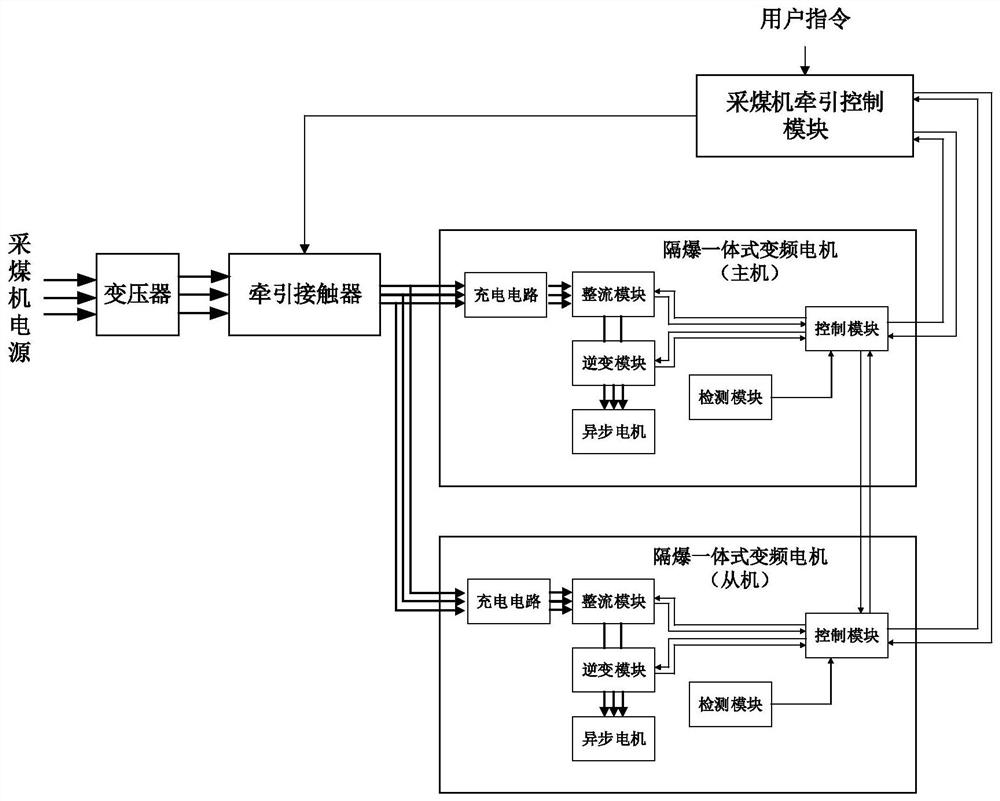

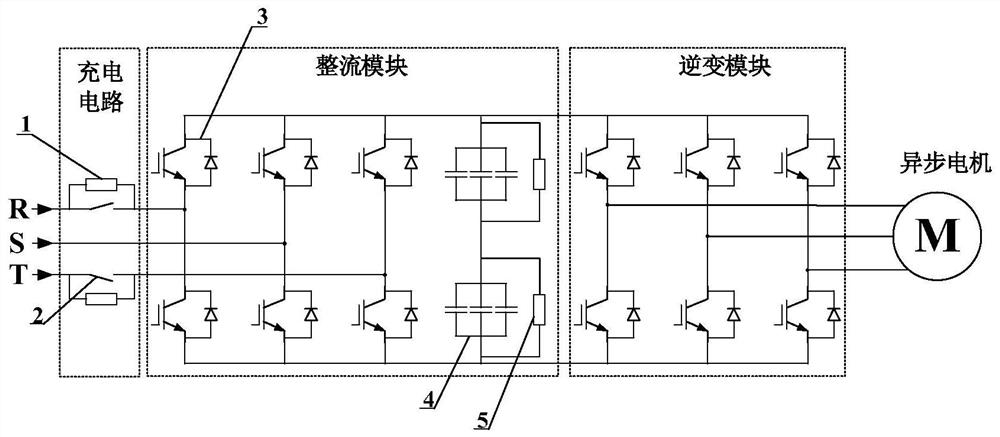

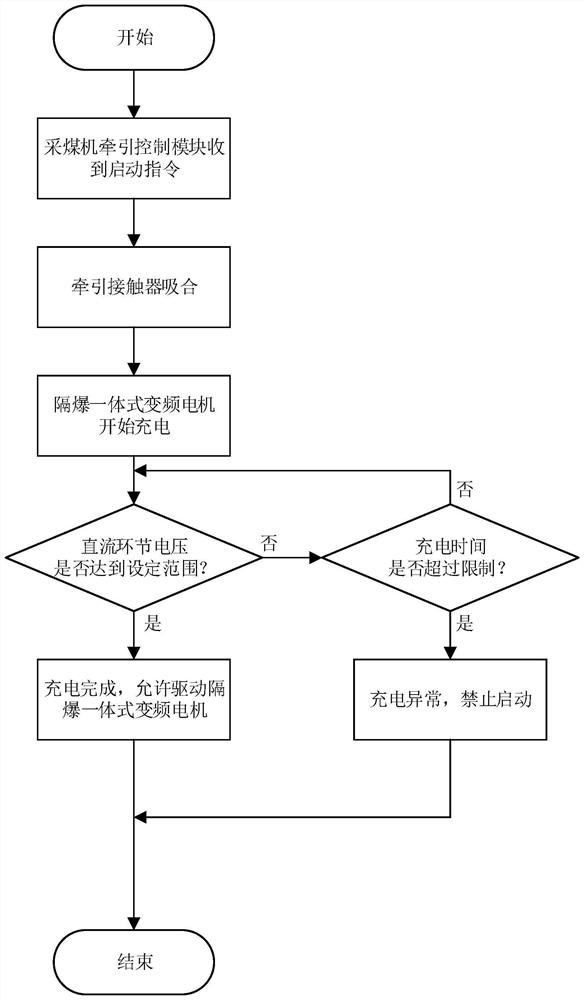

[0031] The invention discloses a shearer traction system, such as figure 1 , 2 As shown, it includes a coal mining machine traction control module and a transformer connected in sequence, a traction contactor and a flameproof integrated frequency conversion motor. The primary side of the transformer is the coal mining machine power input end, and the control circuit of the traction contactor The control input terminal is connected to the control output terminal of the shearer traction control module, the control module of the flameproof integrated frequency conversion motor is connected with the shearer traction control module in two-way communication, and the flameproof integrated frequency conversion motor receives the information from the shearer traction control module. control signal. The shearer traction control module is the control center of the entire shearer traction system, which centrally controls and manages the on-off of the traction contactor and the flameproof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com