Zirconium silicate ball milling process and device

A technology of zirconium silicate and ball milling, which is used in cleaning methods and utensils, grain processing, cleaning hollow objects, etc., can solve the problem that zirconium silicate raw materials are stuck in the feeding box, zirconium silicate cannot be normally unloaded, and normal production is affected. and other problems, to achieve the effect of shortening the ball milling time, preventing clogging and sufficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

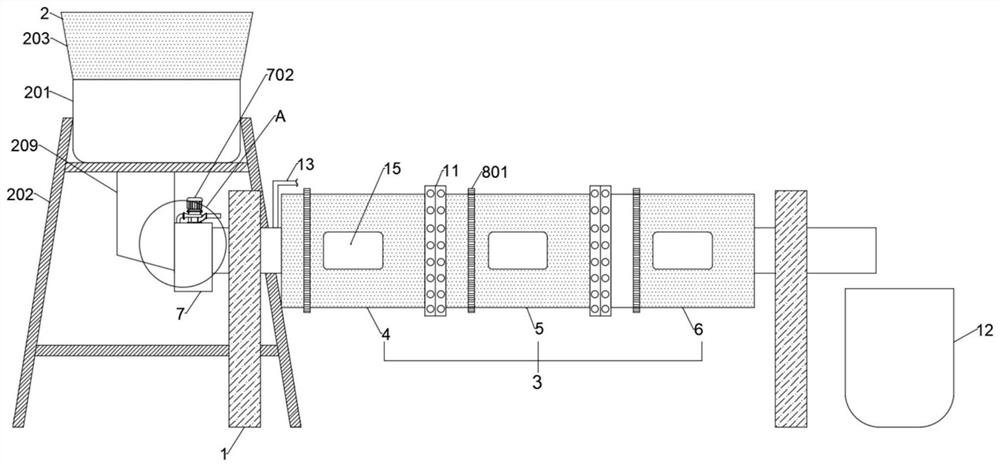

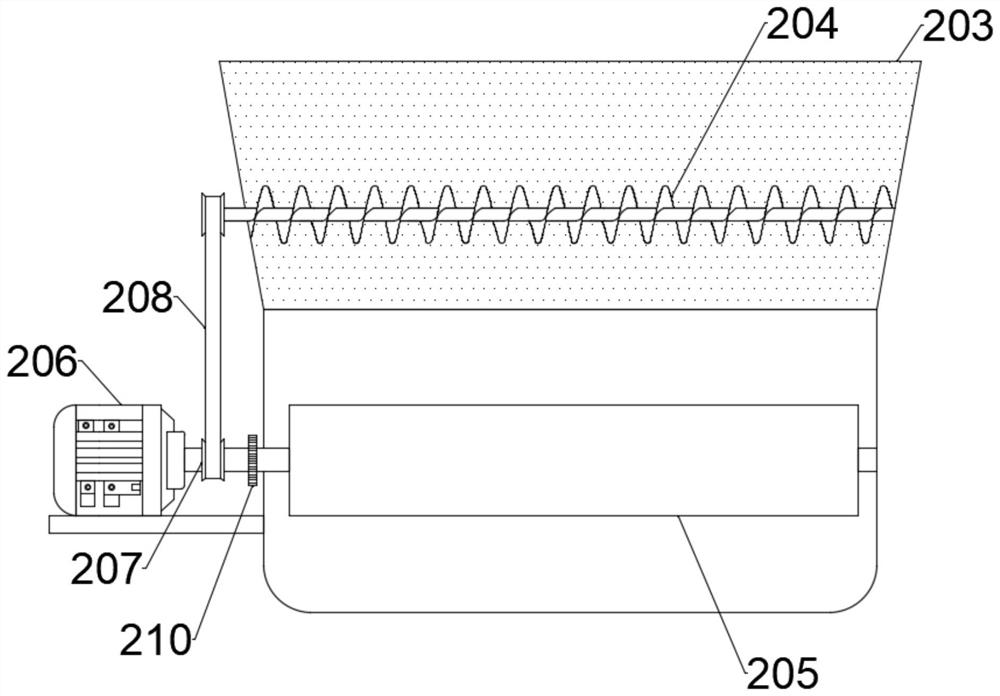

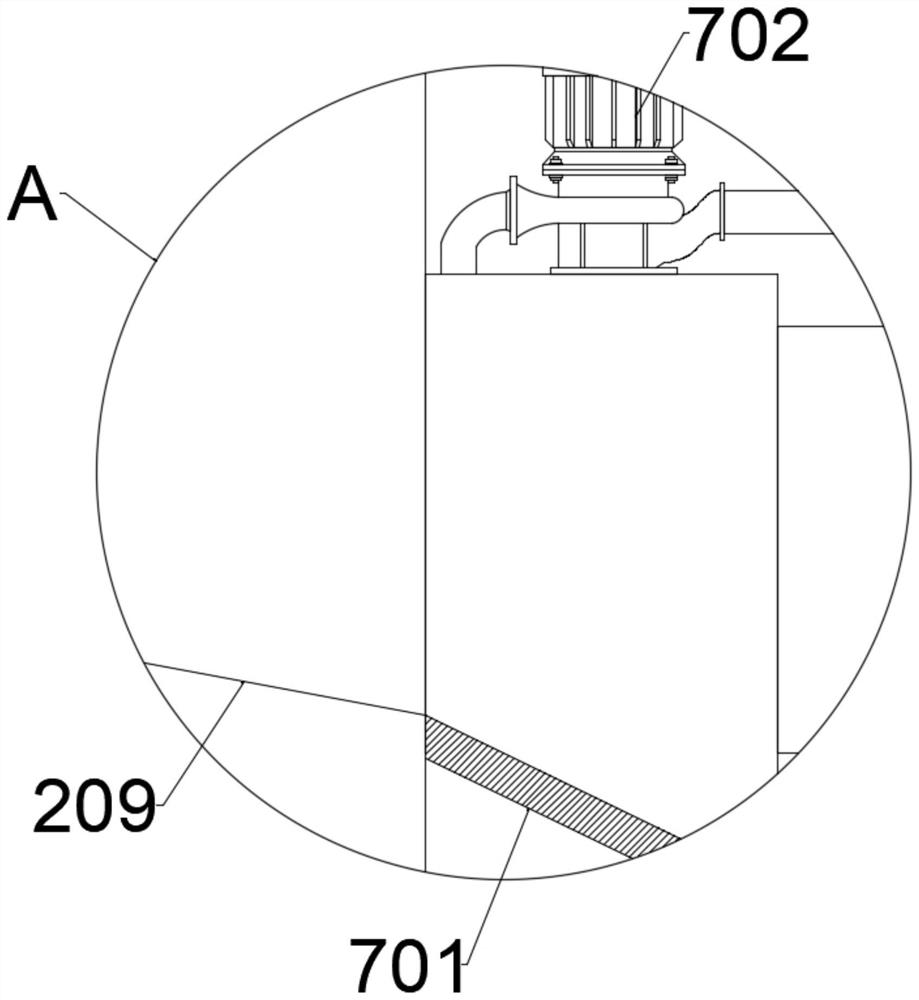

[0035] Such as Figure 1-2 , Figure 4 and Figure 7As shown, a primary grinding assembly 2 is installed on one side of the support frame 1, and a multi-stage ball mill mechanism 3 is installed on the other side of the support frame 1. The first drive motor 206 and the second drive motor 802 are opened, and the first drive motor 206 drives One of the grinding rollers 205 rotates, and the first gear 210 drives the other grinding roller 205 to rotate, and the stirring blade 204 is driven by the rotating wheel 207 and the belt 208 to stir, and the zirconium silicate is put into the feed box 203 and stirred The leaf 204 continuously stirs the zirconium silicate to prevent the large size of the zirconium silicate from entering the grinding box 201 for grinding, and the grinding roller 205 performs primary crushing of the zirconium silicate, which can reduce the number of first-stage ball milling boxes by 4 pairs. The ball milling time of zirconium silicate, after the zirconium si...

Embodiment 2

[0038] Such as figure 1 , Figure 3-8 As shown, the cleaning brush 902 included in the stirring assembly 9 cleans the inner walls of the primary ball milling box 4, the secondary ball milling box 5 and the tertiary ball milling box 6, preventing powdery zirconium silicate from being mixed with water. It is attached to the inner wall of the multi-stage ball mill mechanism 3, and the turning plate 903 connected with the long rod 901 raises the ball milling medium and zirconium silicate, so that the zirconium silicate can be turned over more fully, and the ball milling medium can be carried out from a higher height. The zirconium silicate is ground more fully, and the scraper 904 scrapes off the zirconium silicate powder attached to the outside of the screen 14 to prevent clogging. A screen 14 is installed in the middle of the inside of the body 6. On the one hand, the zirconium silicate that has been milled is filtered and screened, and on the other hand, it is prevented from m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com