Efficient preparation system for waste concrete regenerated sand powder

A waste concrete and preparation system technology, which is applied in the field of high-efficiency preparation system of waste concrete recycled sand powder, can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

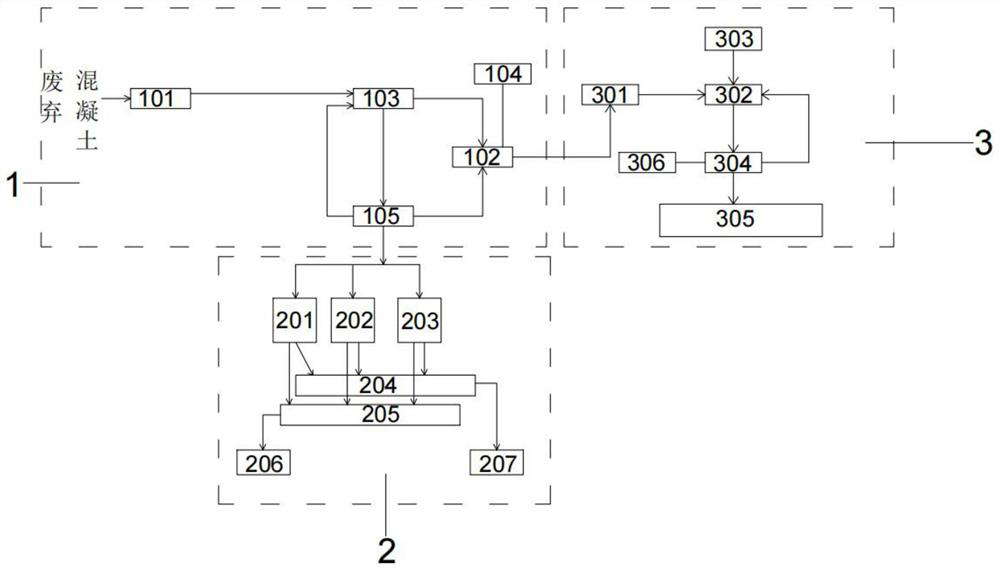

[0039] A high-efficiency preparation system for recycled sand powder from waste concrete, such as Figure 1-3 As shown, it includes: a screening system 1, a deployment system 2 and a regeneration system 3, the screening system 1 is connected to the deployment system 2 and the regeneration system 3 respectively, a cleaning device 1 is provided in the screening system, and the The regeneration system is provided with cleaning device two.

[0040] The beneficial effect of above-mentioned technical scheme is:

[0041] Screening system 1 is used to screen waste concrete to produce recycled sand and fine powder, and the recycled sand produced by screening system 1 is transported to blending system 2, and the fine powder produced by screening system 1 is transported to In the regeneration system 3, the blending system 2 uniformly mixes the reclaimed sand with different particle sizes screened out by the screening system according to a certain proportion, and is used to produce regen...

Embodiment 2

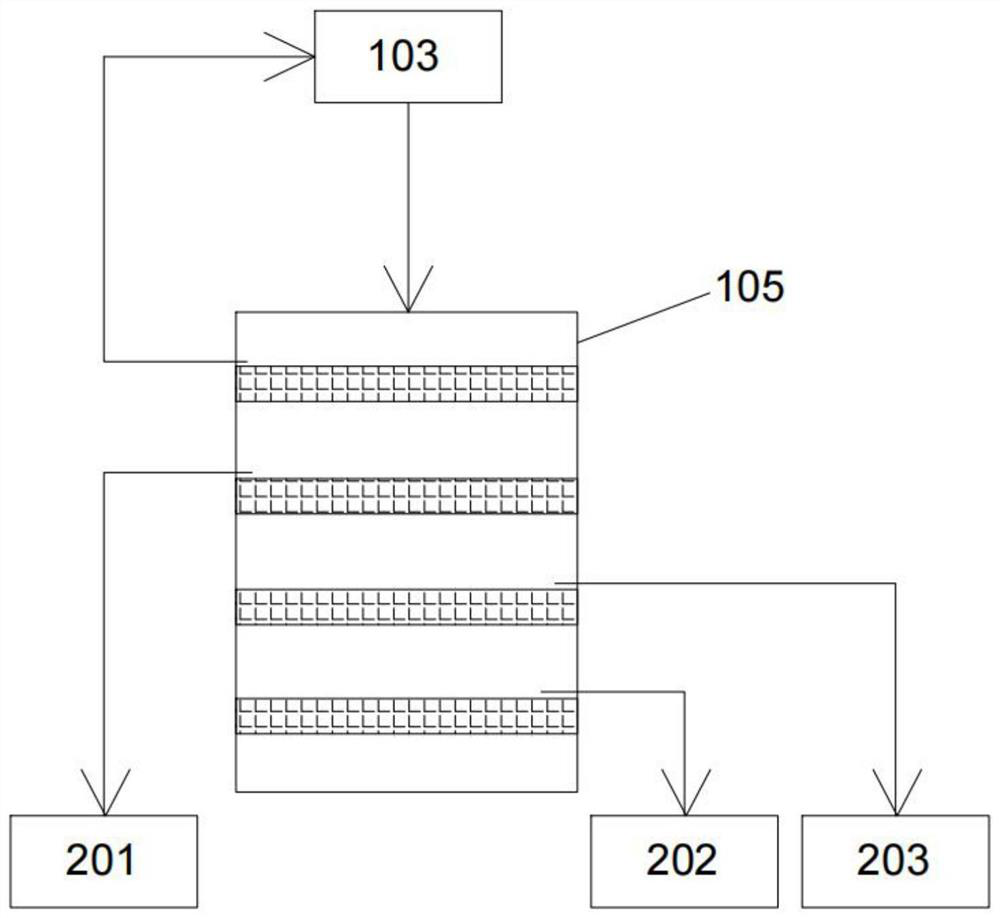

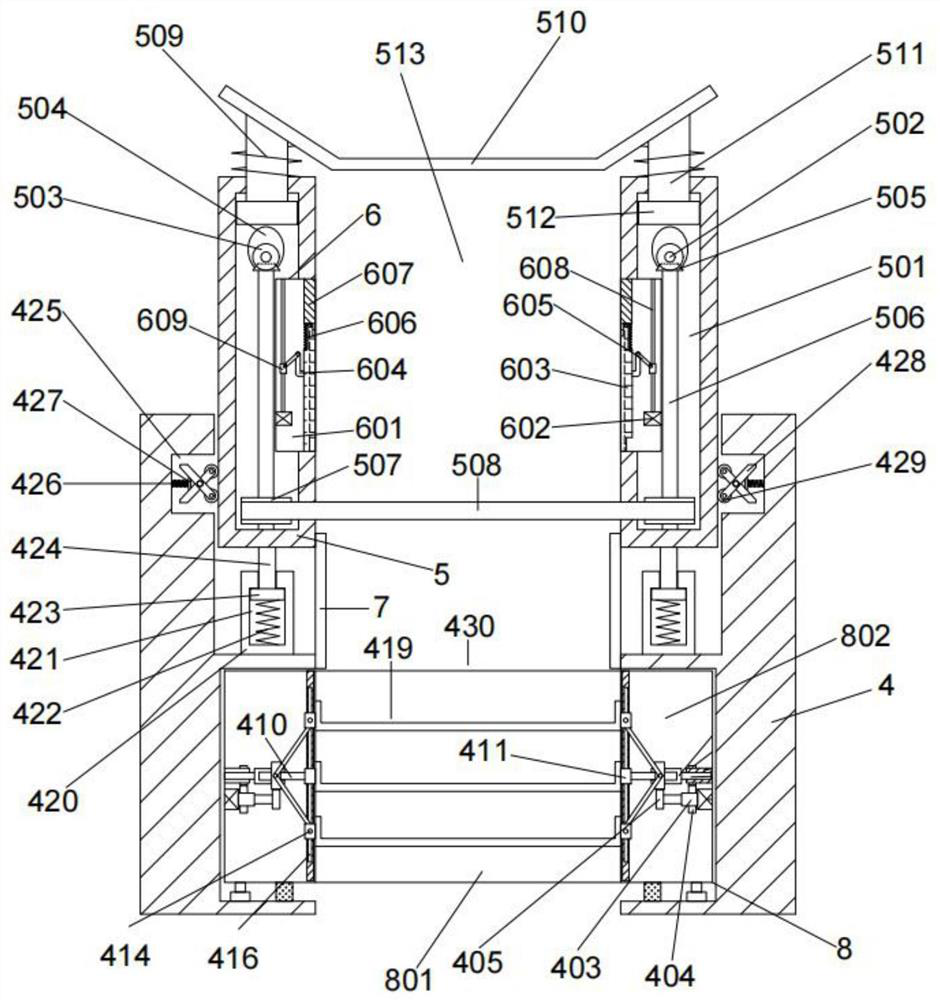

[0043] On the basis of Example 1, such as Figure 4-6 As shown, the screening system includes a waste material feeding device 101, a crushing machine 103 and a screening machine 105. The feed port is connected, and the discharge port of the crushing machine one 103 is connected with the feed port of the screening machine one 105 through the material conveying device two, and the crushing machine one 103 and the screening machine one 105 are respectively connected with the cleaning device One 102, the cleaning device one 102 is connected with a negative pressure device 104;

[0044] The cleaning device one 102 is a filter cartridge dry dust collector, the negative pressure device 104 is a fan one, the air outlet of the crushing machine one 103, the screening machine one 105 is connected with the air inlet of the filter cartridge dry dust collector , the air outlet of the filter cartridge dry dust collector is connected to the air inlet of the fan one, and the air outlet of the...

Embodiment 3

[0050] On the basis of Example 1, such as figure 1 As shown, the deployment system 2 includes a number of the storage warehouses and a number of mixing devices, the storage warehouses are respectively connected to a number of mixing devices through a number of feeding devices, and the feeding devices are used to The materials in the storage warehouse are transferred into the mixing device. Several of the storage warehouses include a regenerated sand warehouse 201, a regenerated sand warehouse 202 and a regenerated sand warehouse 203. The regenerated sand warehouse 1 201 and the regenerated sand warehouse 2 202 and the regenerated sand in the regenerated sand storehouse-203 are different in particle size;

[0051] The several mixing devices include mixing device one 204 and mixing device two 205, the feeding device is a quantitative feeder, the mixing device is a humidifying mixer, and the regenerated sand storehouse one 201, regeneration Sand warehouse two 202, regenerated sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com