Novel anti-backfire gas mixer for gas generator set

A technology of gas mixer and generator set, which is applied in the direction of gas fuel burner, burner, combustion type, etc., can solve the problems of short service life, disperse treatment of gas and air, low mixing rate, etc. probability, the effect of improving gas delivery efficiency, and improving ignition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

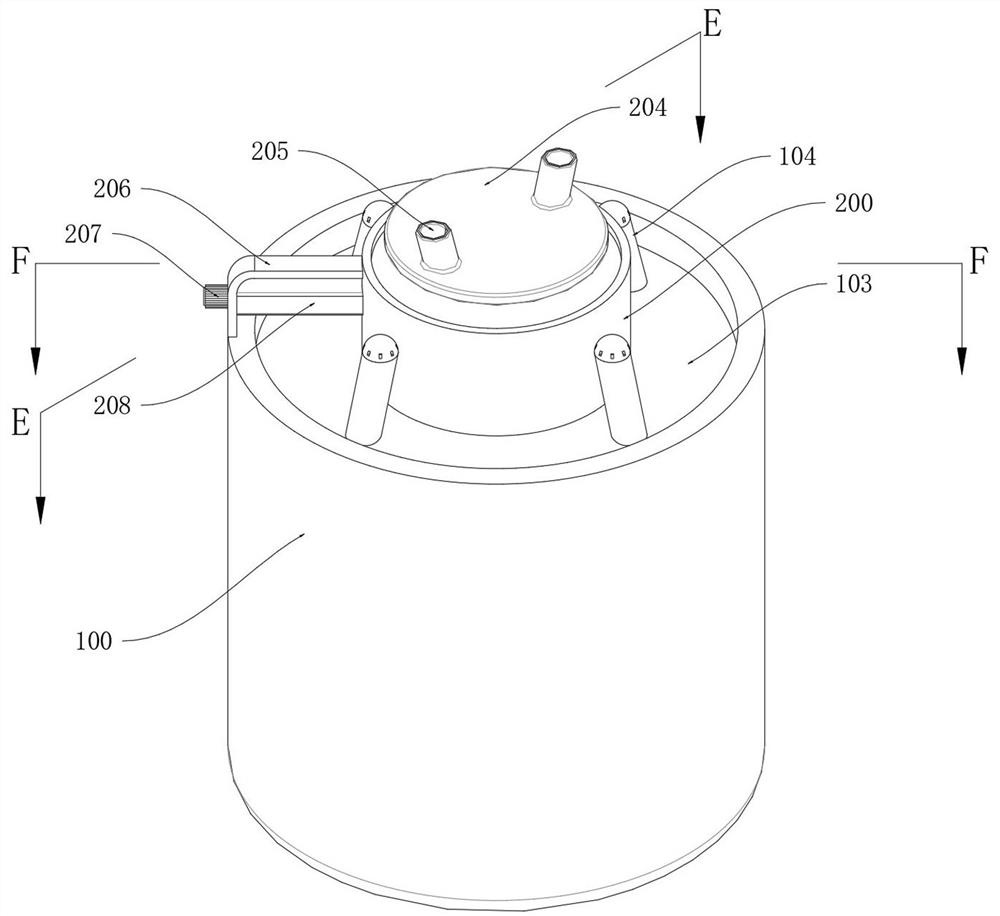

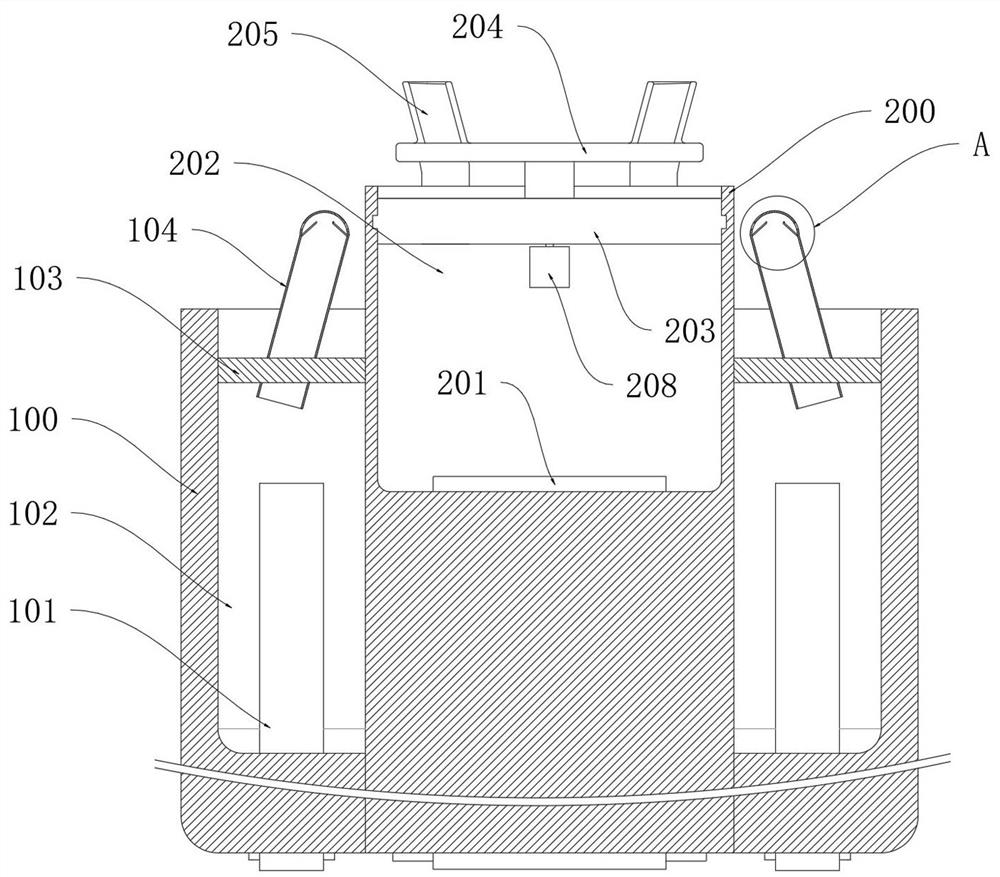

[0034] In order to transport air and gas into the same space, the present invention discloses such as Figure 1-Figure 8 A new anti-backfire gas mixer for a gas generator set as shown, which at least includes an external pipe 100, wherein an internal pipe 200 is sandwiched in the external pipe 100, and the external pipe 100 and the internal pipe 200 are all arranged inside the outer box 300, and the bottom wall of the external delivery pipe 100 and the inner delivery pipe 200 are welded to the bottom wall of the inner cavity of the outer box 300, and the mixing of air and gas is completed in the inner cavity of the outer box 300;

[0035] The internal transportation pipe 200 penetrates the external transportation pipe 100 from the bottom of the external transportation pipe 100, and extends to the top of the external transportation pipe 100, and an annular designed space is formed between the external transportation pipe 100 and the internal transportation pipe 200. It is an in...

Embodiment 2

[0038] In order to disperse the air after it is sent out from the air bypass pipe 101, and mix it with the gas, the present invention discloses such Figure 1-Figure 3 A new anti-backfire gas mixer for a gas generator set is shown, which at least includes a packing plate 103 fixed and sealed on the top of an inner chamber 102 and several circular arrays distributed along the axis of the packing plate 103 There are at least four oblique delivery pipes 104, and at least four oblique delivery pipes 104 are welded with the packing plate 103, and the openings at the bottom of all oblique delivery pipes 104 extend into the inner chamber 102 to realize the ventilation of air. take over;

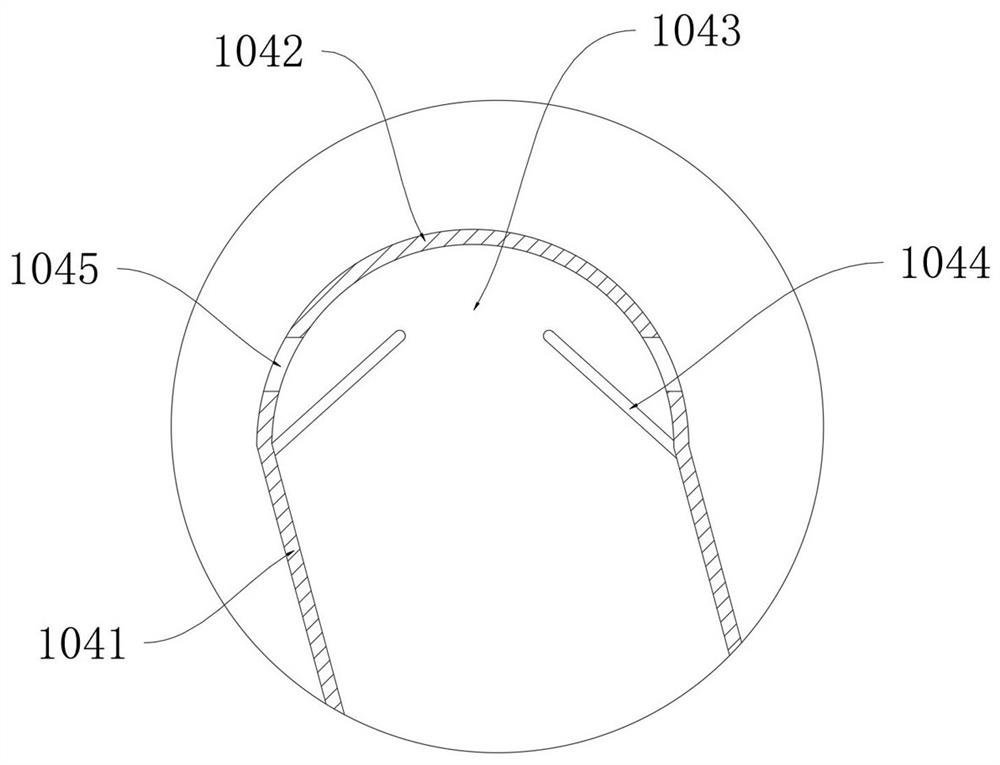

[0039] The inclined feeding pipe 104 is welded by the tube base 1041 and the arc cap 1042. The section of the arc cap 1042 is arc-shaped, and the inner wall of the arc cap 1042 is welded with a circular ring-shaped blocking piece 1044, and the ring-shaped blocking piece 1044 The inside protrudes up...

Embodiment 3

[0042]In order to disperse the gas after entering the inner second chamber 202 and mix it with air, the present invention discloses such figure 2 , Figure 4 and Figure 5 A new anti-backfire gas mixer for a gas generator set is shown, which at least includes a platform cover 203 that is movably sealed on the top of the inner second chamber 202, and an extension tube 205 arranged on the platform cover 203 for dispersing and transporting gas to the outside And the driving facility of the platform cover 203, wherein the driving facility at least includes a cooperating hood 207 and an inner extension seat 208, the hood 207 and the inner extension seat 208 are all arranged on the L-shaped receiving beam 206, and the arrangement is preferably welded ;

[0043] The hood 207 has a built-in drive source, the drive source is preferably a servo motor, and the inner support shaft 209 runs horizontally in the inner extension seat 208, and the inner support shaft 209 is coaxially connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com